Elastic shoe sole with shock absorption effect and preparation method and application thereof

A technology of elasticity and elastomer, applied in the field of shock-absorbing and rebounding shoe soles and its preparation, to achieve the effects of improving comfort experience, simple preparation process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Some embodiments of the present invention provide a method for preparing a shock-absorbing and rebounding shoe sole as described above, comprising the following steps:

[0040] Melting and kneading the thermoplastic elastomer resin, and then blowing and inflating to prepare a plurality of inflatable elastic pellets;

[0041] The plurality of inflatable elastic balls are stacked and placed in the cavity of the midsole mold, and the bottom of the cavity of the midsole mold is placed with a large bottom. After the mold is closed, microwave or radio frequency is used for heating and bonding, and the mold is opened to obtain a shock-absorbing return. Bouncy soles.

[0042] In the embodiment of the present invention, it is preferable to dry and mix the thermoplastic elastomer resin and processing aids, then put them into the barrel of the twin-screw extruder for melt mixing, and then quickly introduce them into the mold for blow molding and inflate after extrusion to obtain m...

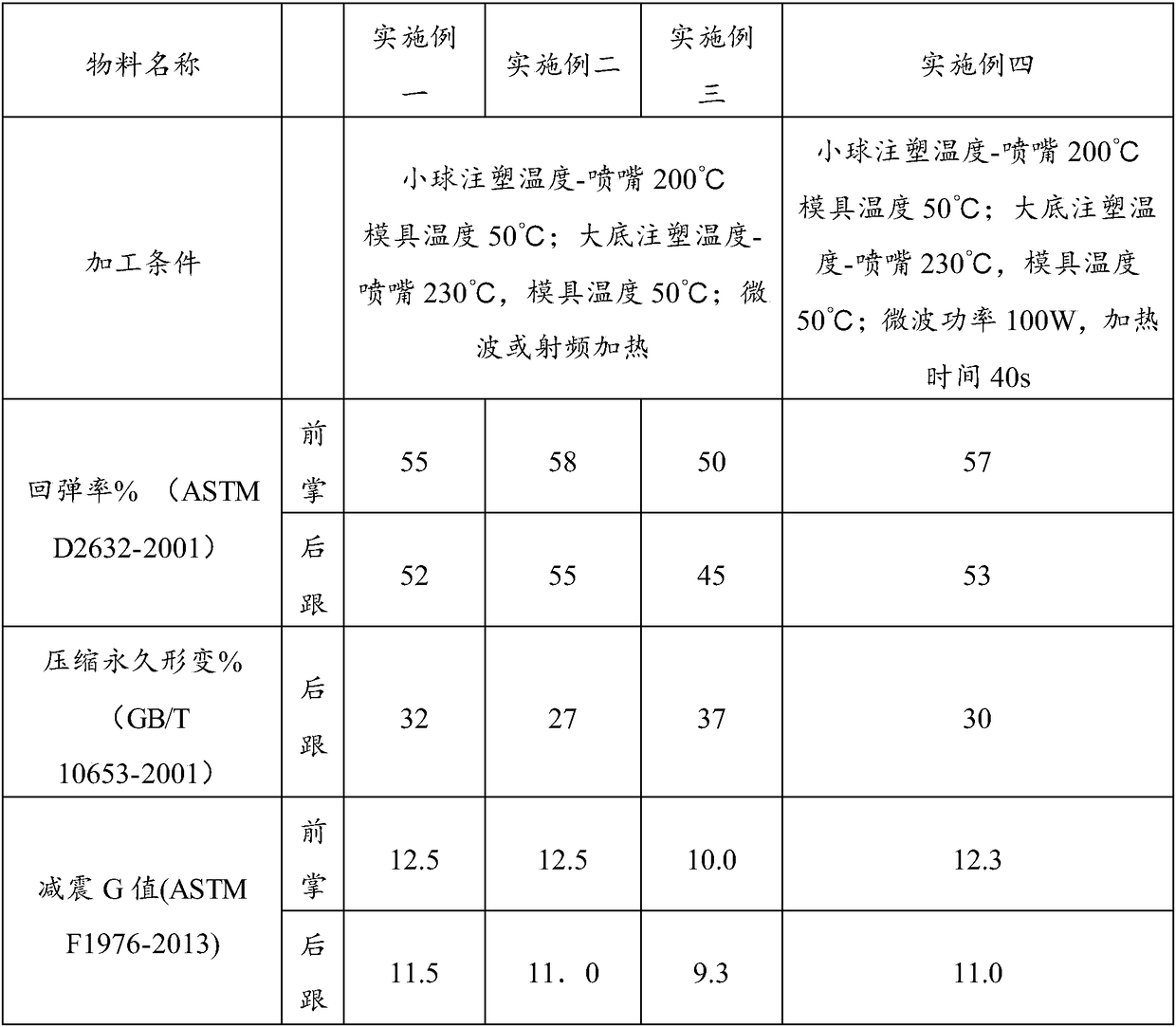

Embodiment 1

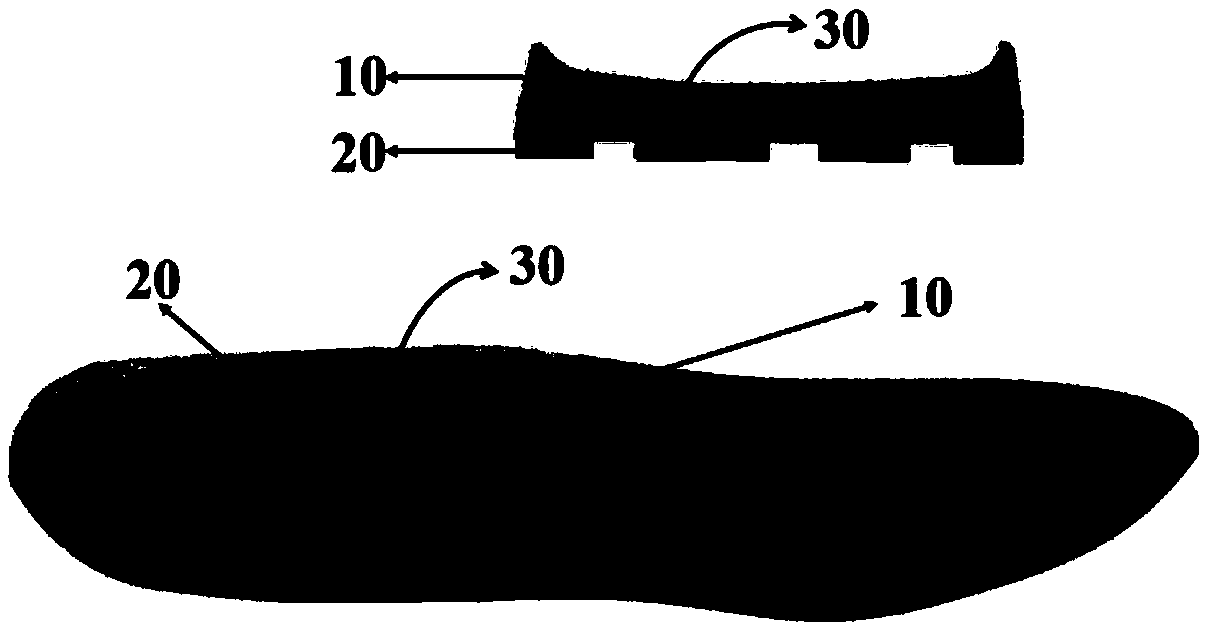

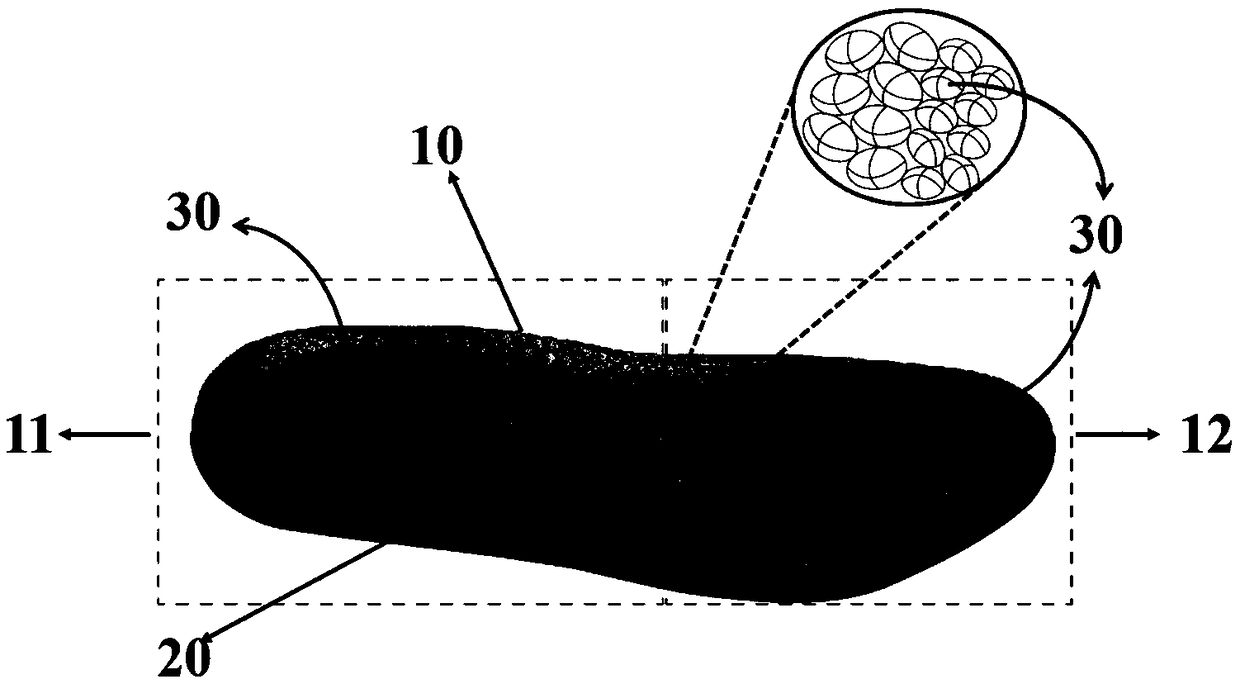

[0050] figure 2 It is a schematic diagram of the sole structure provided by Embodiment 1 of the present invention, wherein 10 is the midsole, 20 is the outsole, 30 is the inflatable elastic ball, 11 is the heel area, and 12 is the forefoot area.

[0051] Such as figure 1 with figure 2 As shown, a transparent high shock-absorbing and rebounding sole includes: a shoe midsole 10 with a TPU hollow elastic ball 30 and a wear-resistant and non-slip TPU outsole 20; wherein, the shoe midsole 10 includes a forefoot region 12 and heel area 11. In this embodiment, the forefoot area 12 includes a hollow elastic ball 30 with a diameter of 3 mm and a thickness of 12 mm; the heel area 11 includes a hollow elastic ball 30 with a diameter of 6 mm and a thickness of 24 mm.

[0052] In an embodiment, thermoplastic polyurethane resin (BASF Elastollan 1185A10, hardness 85A, melt index<20g / 10min, 190°C, 21.6kg), and processing aid (0.2 part of antioxidant AT10, nucleating agent silica 1 part,...

Embodiment 2

[0056] Such as figure 1 As shown, a transparent high-shock-absorbing rebound sole includes: a shoe midsole 10 with a TPU hollow elastic ball 30 and a wear-resistant and non-slip TPU outsole 20 . Wherein, the midsole 10 includes a forefoot area and a heel area. In this embodiment, the forefoot area includes a hollow elastic ball 30 with a diameter of 3 mm and a thickness of 12 mm; the heel area includes a hollow elastic ball 30 with a diameter of 3 mm and a thickness of 24 mm.

[0057] In this embodiment, thermoplastic polyurethane resin (BASF Elastollan 1185A10, hardness 85A, melt index<20g / 10min, 190°C, 21.6kg), and processing aids (0.2 parts of antioxidant AT10, nucleating agent silica 1 part, 0.5 part of lubricant zinc stearate), after drying and stirring and mixing, add to the twin-screw extruder barrel and carry out melt mixing, and then quickly introduce it into the mold for blow molding after extrusion to obtain a hollow ball. Among them, the wall thickness of the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com