Preparation method of 3D printed carbon fiber reinforced aluminum matrix composite

A composite material and reinforced aluminum-based technology, which is applied in the direction of additive processing, can solve the problems of uneven distribution and agglomeration of carbon fibers, and achieve excellent performance, material performance improvement, and performance improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

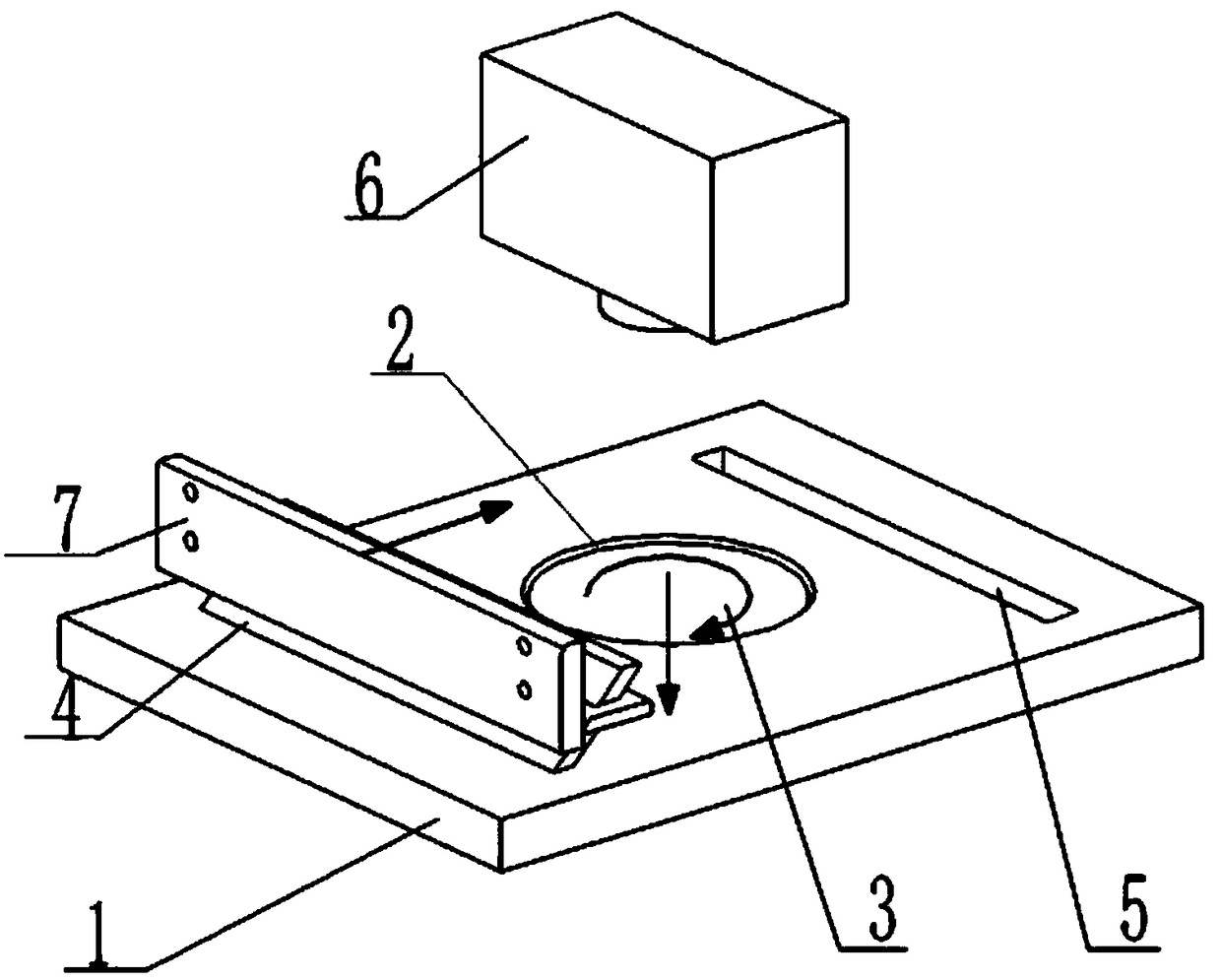

[0029] see figure 1 , figure 2 , Figure 4 and Figure 5 Shown:

[0030] The first step is to design the directional arrangement of carbon fibers:

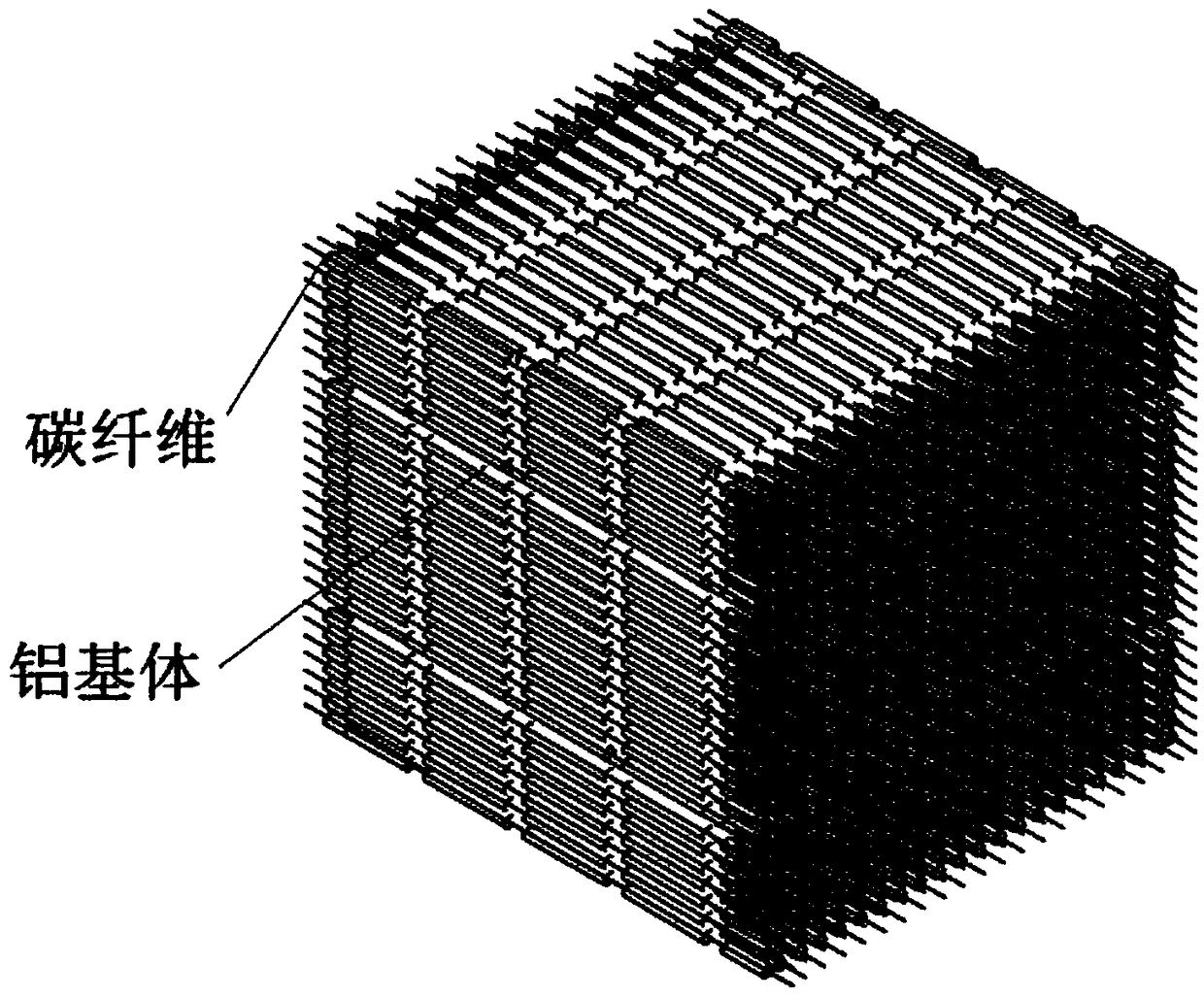

[0031] According to the layout requirements, the thickness of the sample is designed to be 10mm, and the carbon fibers are arranged in parallel between layers (see attached figure 2 ).

[0032] The second step, prepare printing paste:

[0033] Take 2% of carbon fiber, 80% of aluminum powder and 18% of photosensitive resin according to the mass percentage, and stir the three into a uniform slurry by mechanical stirring, the stirring time is 25min, and the stirring speed is 90r / min.

[0034] The third step, 3D printing CF / Al composite material blank:

[0035] According to the carbon fiber arrangement in the first step, divide the whole material into 20 equal layers horizontally, each layer is 0.5mm, and print layer by layer from bottom to top; (3) Drop 0.5mm at a speed of 0.25mm / s. Pour the slurry into the mold groove (2)...

Embodiment 2

[0041] see figure 1 , image 3 , Figure 6 and 7 Shown:

[0042] The first step is to design the directional arrangement of carbon fibers:

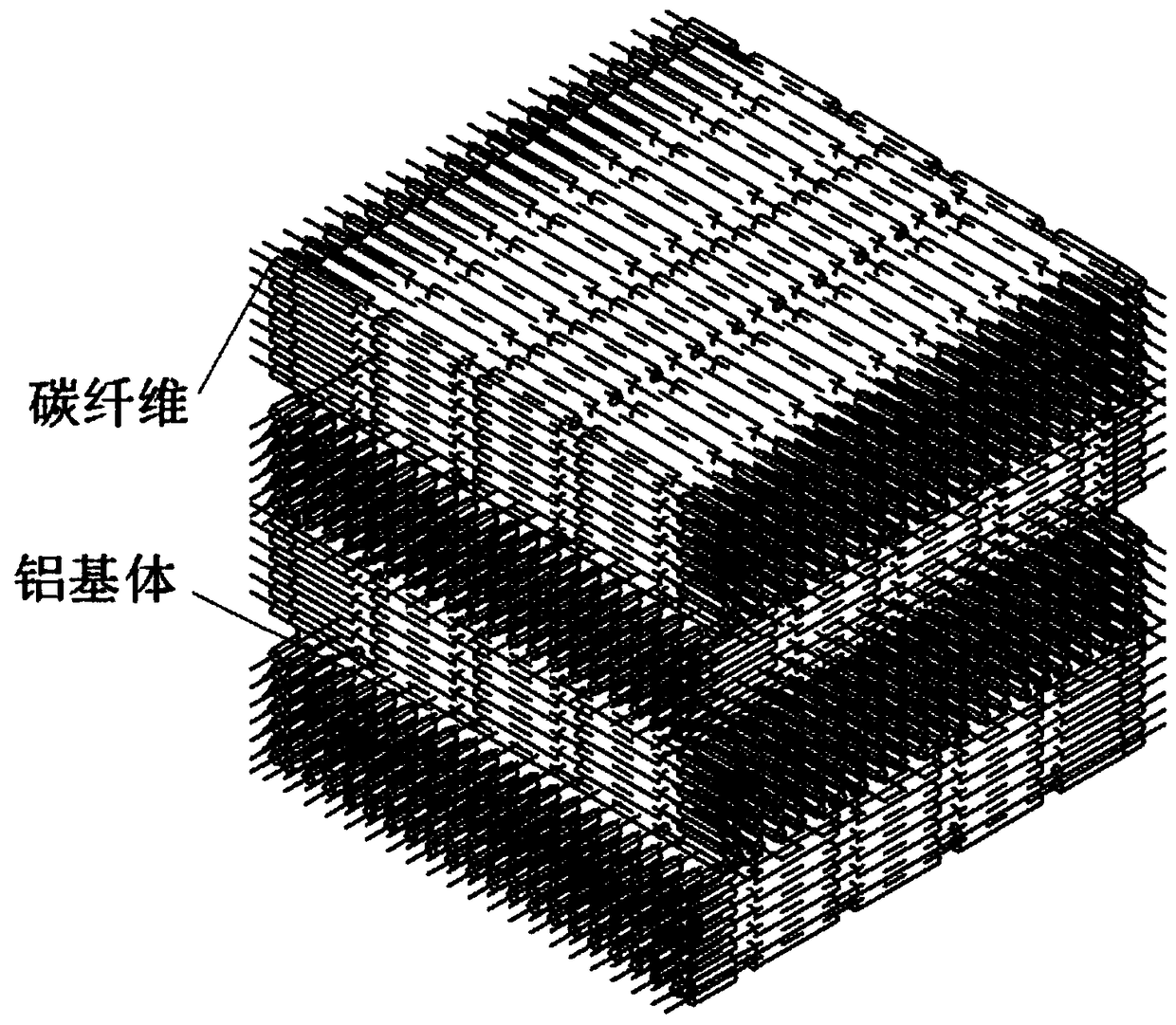

[0043] According to the requirements, the thickness of the sample is designed to be 12mm, and the carbon fibers between adjacent layers are arranged vertically to each other (see attached image 3 ).

[0044] The second step, prepare printing paste:

[0045] Take 3% of carbon fiber, 75% of aluminum powder and 22% of photosensitive resin by mass percentage. The three are stirred into a homogeneous slurry by means of mechanical stirring, the stirring time is 40min, and the stirring speed is 150r / min.

[0046] The third step, 3D printing CF / Al composite material blank:

[0047] According to the carbon fiber arrangement in the first step, divide the whole material into 40 layers horizontally, each layer is 0.3mm, and print layer by layer from bottom to top; (3) Drop 0.3mm at a speed of 0.2mm / s. The slurry is poured into the mold groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com