High-temperature-resistant environmental barrier coating and preparation method thereof

An environmental barrier coating and high temperature resistant technology, which can be used in coatings, metal material coating processes, melt spraying, etc. less, low thermal expansion coefficient, good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

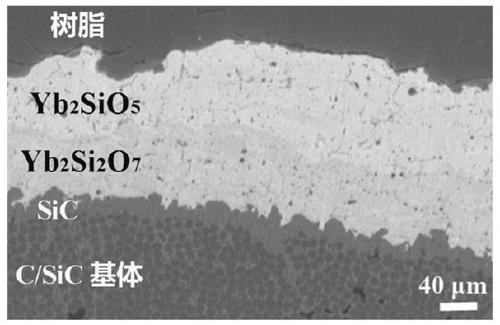

[0045] Preparation of the middle layer. By plasma spraying method, the Yb 2 Si 2 o 7 The powder is sprayed onto a substrate with a SiC bond coat. Wherein, the thickness of the intermediate layer in the high-temperature-resistant environment barrier coating may be 5-200 μm, preferably 30-200 μm. The parameters of the plasma spraying process include: plasma gas Ar: 35-55 slpm; powder carrier gas Ar: 2-7 slpm; plasma gas H 2 : 5~15slpm; Spraying distance: 90~200mm; Spraying power: 30~50kw; Powder feeding rate: 10~35r / min.

[0046] Preparation of toppings. Rare earth monosilicate ((Re 2 SiO 5 , for example: Y 2 SiO 5 、Sc 2 SiO 5 、Gd 2 SiO 5 、Er 2 SiO 5 、Tm 2 SiO 5 , Yb 2 SiO 5 、Lu 2 SiO 5 At least one of the) powder spraying on the surface with SiC bonding layer and Yb 2 Si 2 o 7 On the substrate of the intermediate layer, the high temperature resistant environment barrier coating is prepared. Wherein the surface layer in the environmental barrier coating ...

Embodiment 1

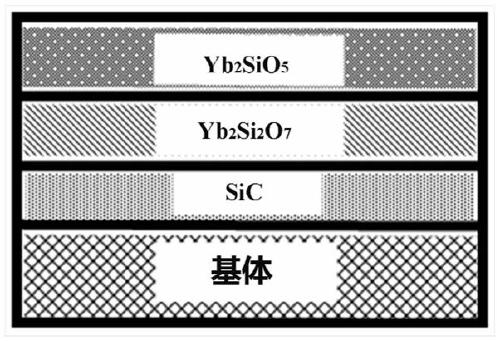

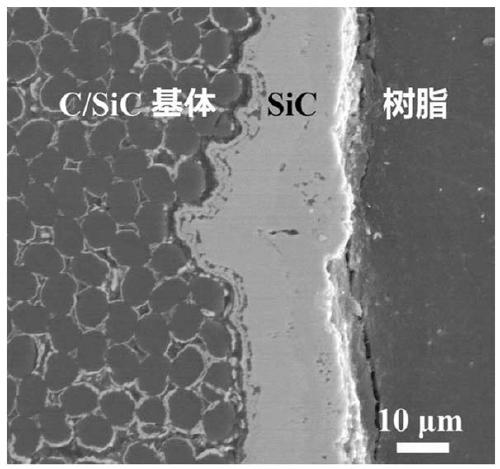

[0050] Preparation of SiC / Yb on C / SiC Composite Matrix 2 Si 2 o 7 / Yb 2 SiO 5 Coating, the coating is composed of 3 layers, from the inner layer to the outer layer, its composition is: bonding layer: SiC; middle layer: Yb 2 Si 2 o 7 ; Surface layer: Yb 2 SiO 5 .

[0051] The steps of coating preparation are as follows:

[0052] Step 1: Sandblasting the surface of the C / SiC composite material substrate with a sandblasting pressure of 0.3MPa;

[0053] Step 2: Prepare a Si coating on the surface pretreated C / SiC composite material substrate by plasma spraying method; the spraying process parameters are shown in Table 1, and the thickness of the silicon coating is 150 μm;

[0054] Table 1 is the process parameters of plasma spraying Si coating

[0055] Plasma gas Ar

34 slpm

Powder carrier gas Ar

4slpm

Plasma gas H2

10slpm

Spray distance

130mm

Spraying power

37kw

Powder feeding rate

20rpm

[0056] *slpm: st...

Embodiment 2

[0067] The difference between this embodiment and the coating described in Embodiment 1 is that the base material used is a C / C composite material, and the rest are the same as in Embodiment 1. The resulting high-temperature-resistant environment barrier coating is shown in the physical picture Figure 7 Shown in (a).

[0068] After 10 and 20 thermal shock experiments (T=1500°C), the coating remained intact, and no peeling occurred on the surface of the sample ( Figure 7 (b) and (c)). It shows that the coating structure prepared in this example maintains good high temperature stability and thermal shock resistance in an environment of 1500°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com