Antibacterial fabric and production process thereof

A production process and technology of antibacterial fabrics, applied in the field of fabrics, can solve the problems of poor antibacterial effect, inconspicuous antibacterial effect, and low comfort, and achieve the effect of good effect, good comfort, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

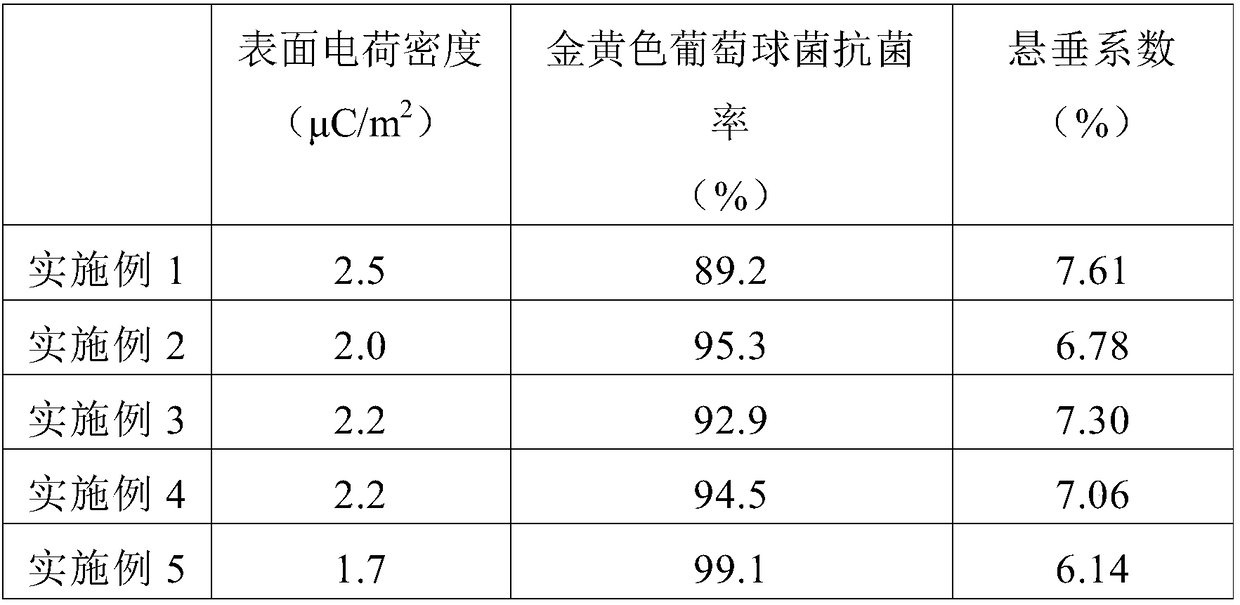

Examples

Embodiment 1

[0028] The production process of antibacterial fabric comprises the following steps:

[0029] (1) 8 parts by weight of water-based polyurethane emulsion, 0.9 parts by weight of carbon nanotubes, 0.4 parts by weight of surfactant, 0.5 parts by weight of sodium polyacrylate, 0.3 parts by weight of coupling agent, and 0.6 parts by weight of antimicrobial agent are added to 90 parts by weight to remove Stir in deionized water at a speed of 300r / min for 20min and mix evenly to obtain a finishing solution;

[0030] (2) Immerse the fabric in the finishing solution at a bath ratio of 1:40 (g / mL) for 60 minutes, the dipping temperature is 40°C, one dipping and one rolling, the excess rate is 75%, the fabric is taken out, and pre-baked at 95°C After 4 minutes, dry at 40°C for 30 hours to obtain an antibacterial fabric.

[0031] The surfactant is dodecyltrimethylammonium chloride.

[0032] The antibacterial agent is chitosan biguanide hydrochloride.

[0033] The coupling agent is 3-(m...

Embodiment 2

[0038] The production process of antibacterial fabric comprises the following steps:

[0039] (1) 8 parts by weight of water-based polyurethane emulsion, 0.9 parts by weight of modified carbon nanotubes, 0.4 parts by weight of surfactant, 0.5 parts by weight of sodium polyacrylate, 0.3 parts by weight of coupling agent, and 0.6 parts by weight of antibacterial agent are added to 90 parts by weight in turn One part of deionized water was stirred at a speed of 300r / min for 20min and mixed evenly to obtain a finishing solution;

[0040] (2) Immerse the fabric in the finishing solution at a bath ratio of 1:40 (g / mL) for 60 minutes, the dipping temperature is 40°C, one dipping and one rolling, the excess rate is 75%, the fabric is taken out, and pre-baked at 95°C After 4 minutes, dry at 40°C for 30 hours to obtain an antibacterial fabric.

[0041] The surfactant is dodecyltrimethylammonium chloride.

[0042] The antibacterial agent is chitosan biguanide hydrochloride.

[0043] T...

Embodiment 3

[0049] The production process of antibacterial fabric comprises the following steps:

[0050] (1) 8 parts by weight of water-based polyurethane emulsion, 0.9 parts by weight of modified carbon nanotubes, 0.4 parts by weight of surfactant, 0.5 parts by weight of sodium polyacrylate, 0.3 parts by weight of coupling agent, and 0.6 parts by weight of antibacterial agent are added to 90 parts by weight in turn One part of deionized water was stirred at a speed of 300r / min for 20min and mixed evenly to obtain a finishing solution;

[0051] (2) Immerse the fabric in the finishing solution at a bath ratio of 1:40 (g / mL) for 60 minutes, the dipping temperature is 40°C, one dipping and one rolling, the excess rate is 75%, the fabric is taken out, and pre-baked at 95°C After 4 minutes, dry at 40°C for 30 hours to obtain an antibacterial fabric.

[0052] The surfactant is dodecyltrimethylammonium chloride.

[0053] The antibacterial agent is chitosan biguanide hydrochloride.

[0054] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com