A kind of road asphalt material cold recycling equipment

A road asphalt, cold recycling technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of low foaming rate of asphalt and low foaming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is further described in detail through specific implementation methods:

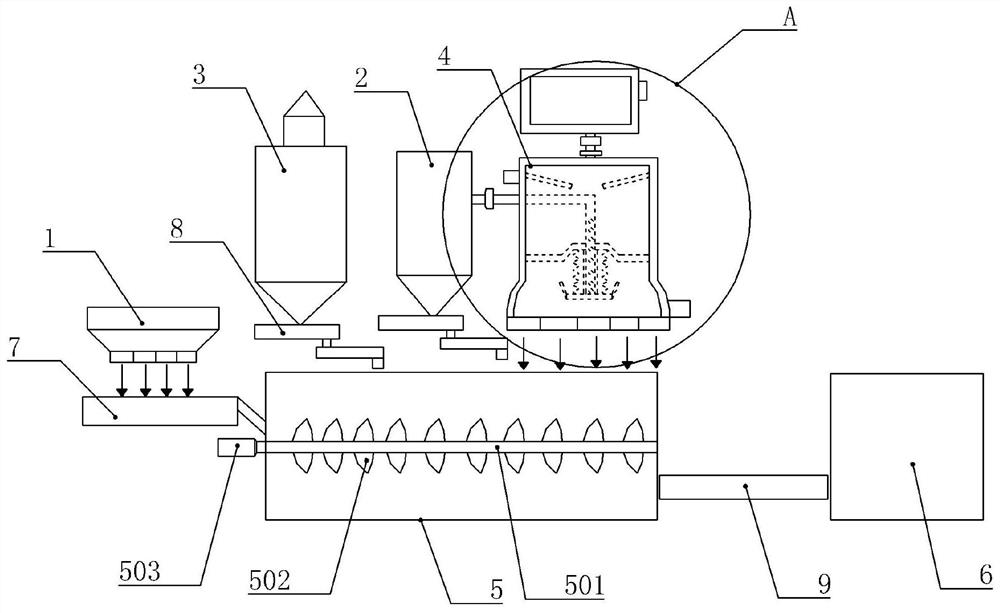

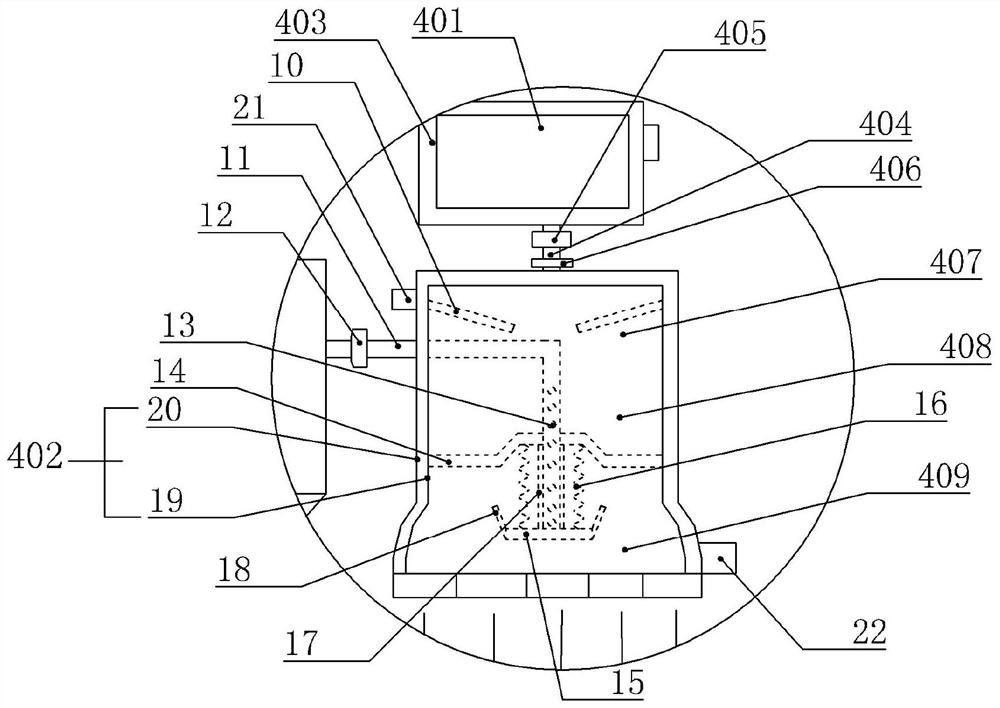

[0016] The reference signs in the accompanying drawings of the specification include: old asphalt material storage mechanism 1, water storage mechanism 2, cement storage mechanism 3, foamed asphalt storage mechanism 4, heating tank 401, pipe body 402, first interlayer 403, first channel Liquid pipe 404, asphalt injection pump 405, control valve 406, entry section 407, mixing section 408, discharge section 409, mixing box 5, rotating shaft 501, stirring blade 502, first motor 503, collection box 6, first transmission Mechanism 7, rotary valve decrement scale 8, second transmission mechanism 9, deflector 10, water pipe 11, water pump 12, water hole 13, mixing platform 14, fixed plate 15, first spring 16, elastic pipe 17, Seal block 18, inner pipe 19, outer pipe 20, oil inlet 21, oil outlet 22.

[0017] Example figure 1 and figure 2 Shown: a road asphalt material cold recycling equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com