Oil cylinder fast movement device and control mode

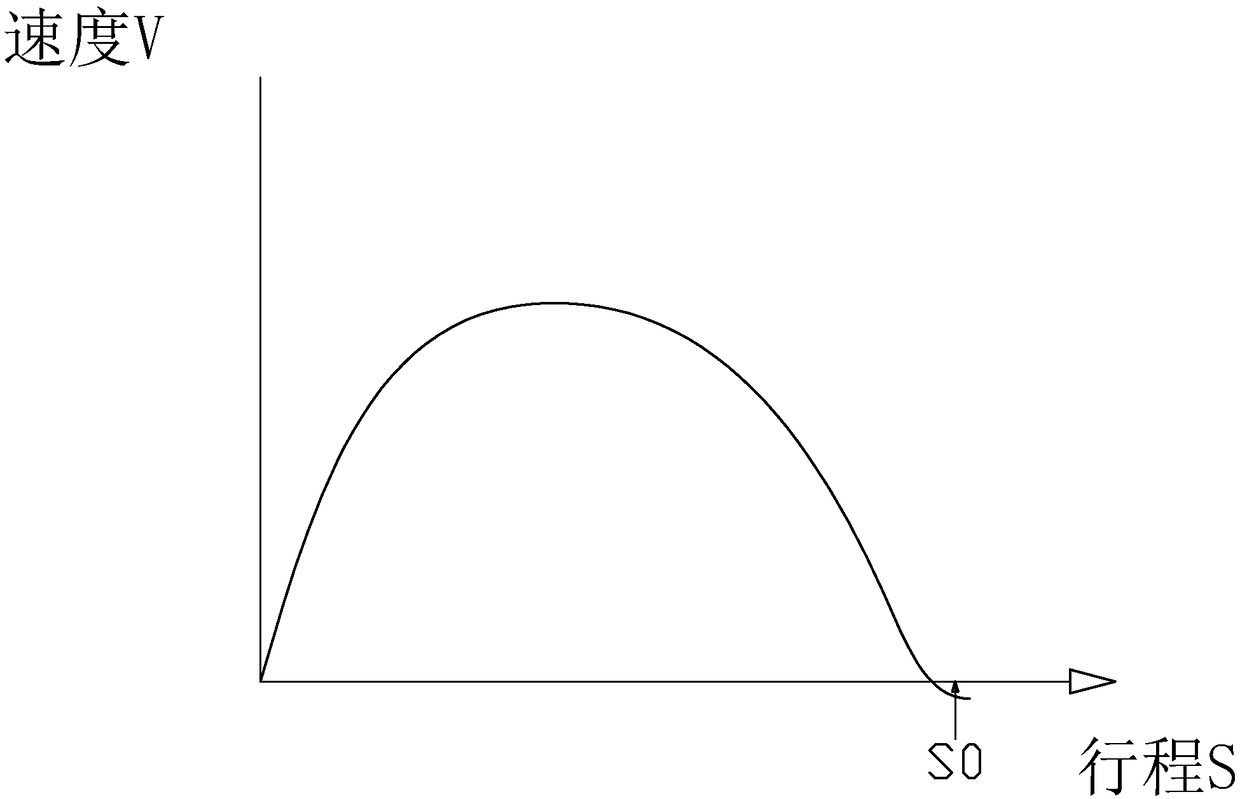

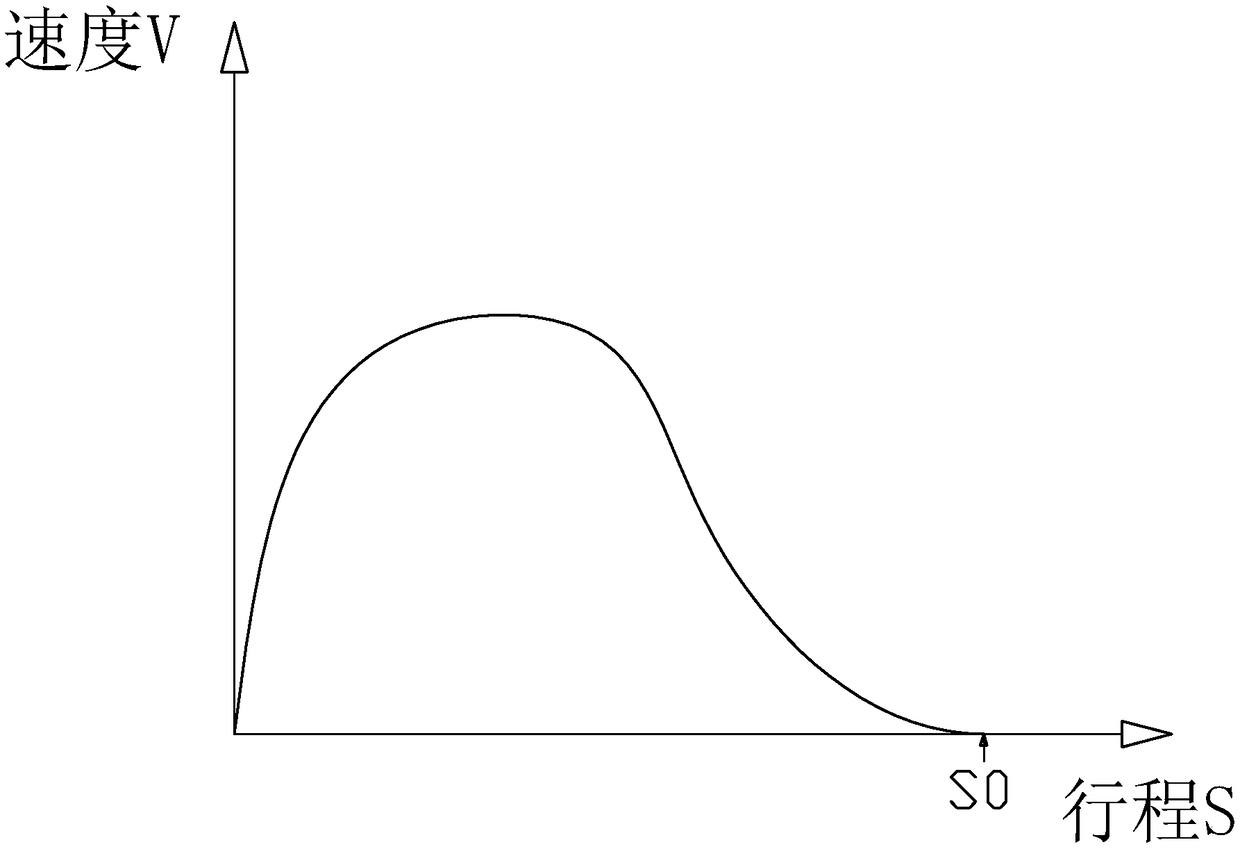

A fast-moving, oil-cylinder technology, used in fluid pressure actuating devices, fluid pressure actuating system testing, servo motors, etc., can solve problems such as longer movement time of oil cylinders, difficulty in stopping accurate stops, and rapid changes in servo pump displacement. Achieve the effect of simple structure, precise and controllable piston rod position, and short movement period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

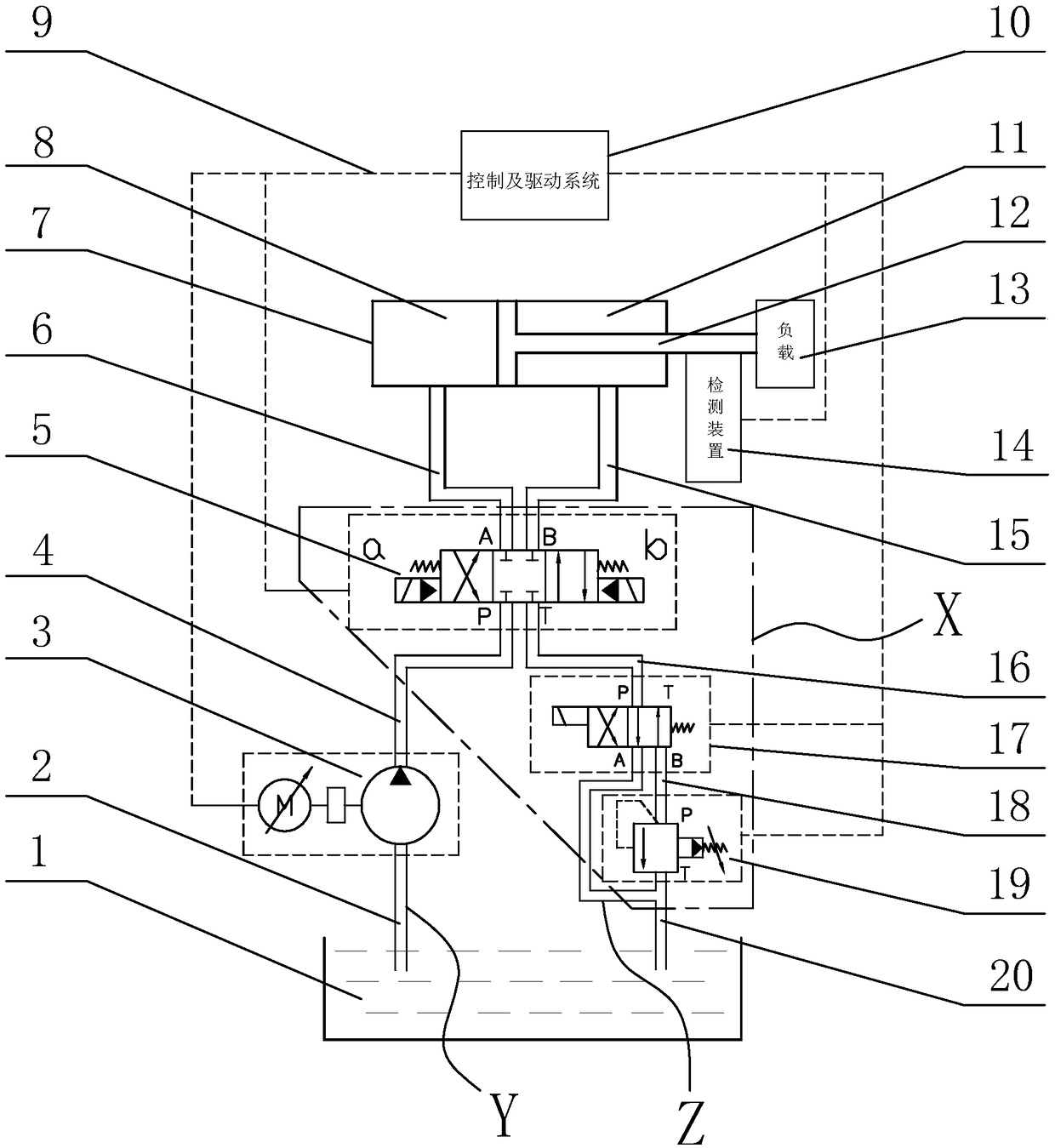

[0030] The present invention will be further described in detail below in conjunction with the embodiments in the accompanying drawings.

[0031] like image 3 As shown, the oil cylinder rapid movement device of the present invention includes a fuel tank 1, a servo motor pump unit 3, a pipeline structure X, a direction control mechanism Y, and a load 13, wherein a piston rod 12 is arranged in the oil cylinder 7, and the piston rod 12 divides the oil cylinder into 7 points. The rod chamber 11 and the rodless chamber 8, the load 13 is fixed on the piston rod 12, the oil tank 1, the servo motor pump unit 3, the direction control mechanism Y, the rodless chamber 8, and the rod chamber 11 pass through the pipeline structure X connection, it is characterized in that: the oil cylinder rapid movement device is provided with a control and drive system 10 and a detection device 14, and the detection device 14 is fixed on the piston rod 12 to detect the moving position of the piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com