Method and device for aftertreatment of exhaust gases of internal combustion engines

An internal combustion engine and reprocessing technology, which is applied to the electronic control of exhaust treatment devices, mechanical equipment, exhaust treatment, etc., can solve the problem of expensive sensor devices, failure to reach the regeneration temperature of the regenerated particulate filter, and nitrogen oxides that cannot be catalyzed in three ways Converter conversion and other issues to achieve the effect of avoiding the remaining loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

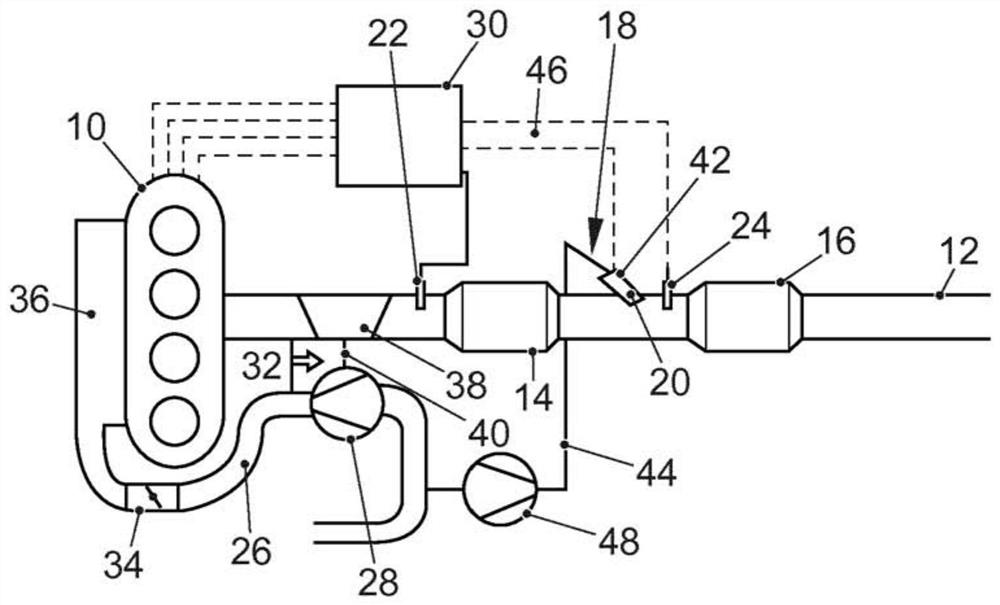

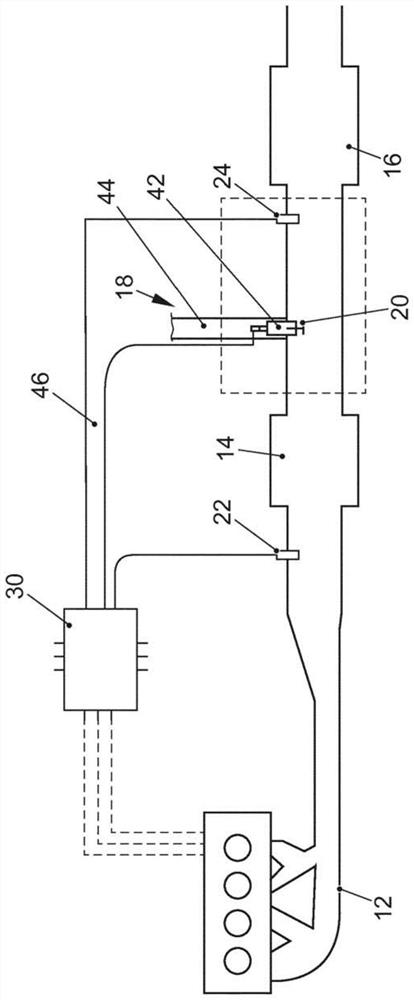

[0033] figure 1 An internal combustion engine 10 in the form of a gasoline engine equipped with a turbocharger 32 is shown having an intake duct 26 and an exhaust gas duct 12 . A compressor 28 , a throttle valve 34 and a charge air cooler 36 are arranged in the intake passage 12 . Arranged in the exhaust gas duct 12 in the flow direction of the exhaust gas of the internal combustion engine 10 is a turbine 38 of a turbocharger 32 which drives a compressor 28 of the turbocharger 32 via a drive shaft 40 . Alternatively, the compressor 28 can also be designed as a mechanically driven compressor or as an electric compressor.

[0034] Downstream of the turbine 38 in the flow direction of the exhaust gas of the internal combustion engine 10 through the exhaust gas passage 12 , a three-way catalytic converter 14 is arranged in the exhaust gas passage 12 . In this case, the three-way catalytic converter 14 is preferably arranged close to the engine in order to enable rapid heating of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com