Formaldehyde degradation filter screen, preparation method thereof and purifier

A formaldehyde purification and filter screen technology, applied in the field of air purification, can solve the problems of unenvironmental protection of the catalyst production process, the toxic cost of the reactant, and the unenvironmental health, etc., to achieve high-efficiency formaldehyde removal effect, improve formaldehyde removal effect, and improve air contact speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing the formaldehyde-removing filter screen described in the above technical solution, comprising the following steps:

[0043] a) impregnating the small carrier with a guanine solution, and then drying to obtain a small carrier loaded with a guanine active ingredient;

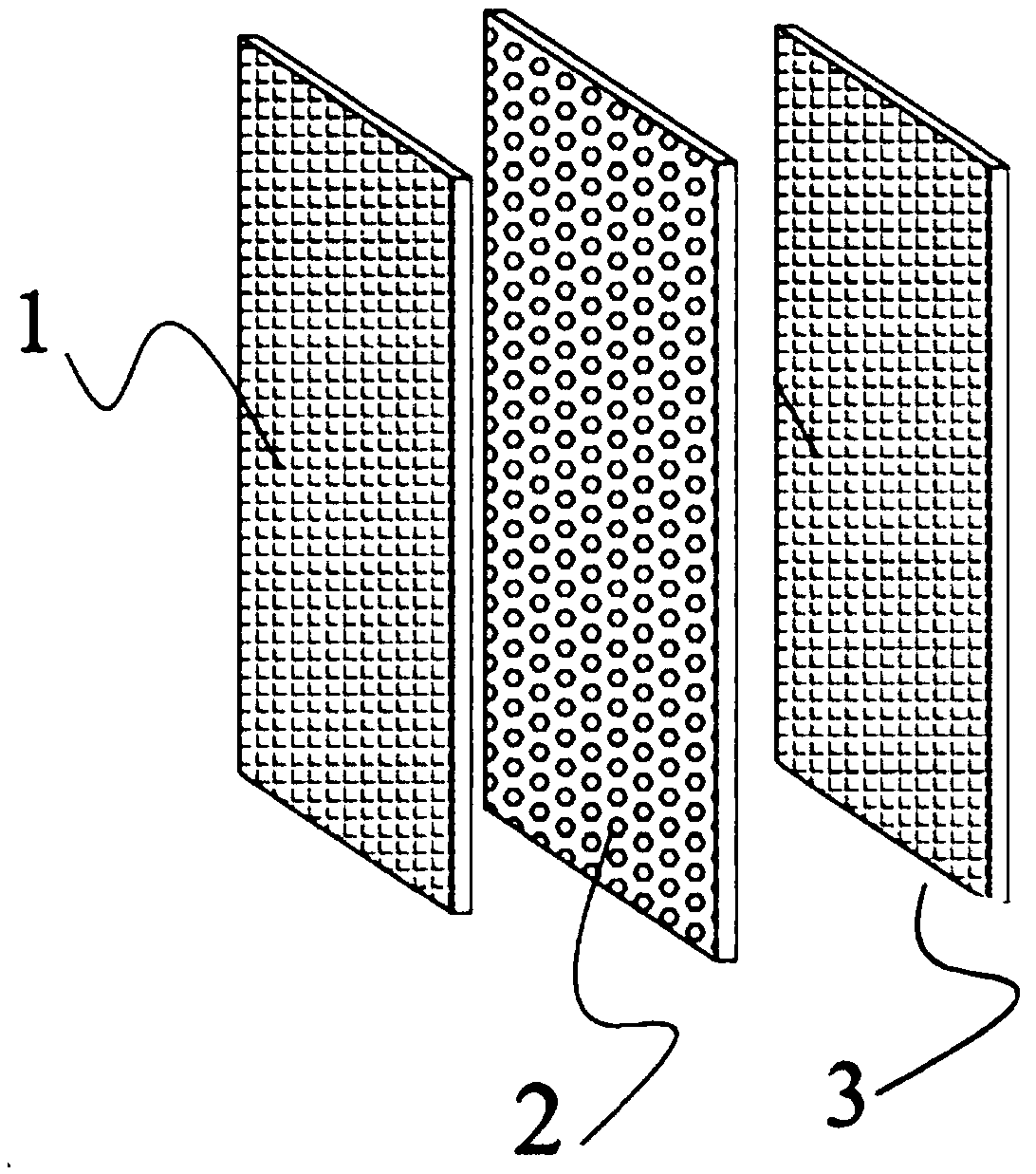

[0044] b) immobilizing the small carrier loaded with the guanine active ingredient on a porous large carrier to obtain a formaldehyde purification layer;

[0045] c) Fixing primary effect mesh cloth layers on both sides of the formaldehyde purification layer to obtain a formaldehyde removal filter.

[0046] Wherein, the types, characteristics and sources of the guanine, the small carrier, the porous large carrier and the primary effect mesh layer are all consistent with those described in the above technical solution, and will not be repeated here.

[0047] According to the present invention, the small carrier is impregnated with the guanine soluti...

Embodiment 1

[0058] 4L coconut shell activated carbon carrier (20-40 mesh, specific surface area is 1200m 2 / g) Soak in 3000g mass concentration of 10% guanine aqueous solution, the soaking temperature is 60 DEG C, the time is 2 hours, then remove the water by suction filtration, and bake at 100 DEG C for 2 hours to obtain the small carrier loaded with guanine .

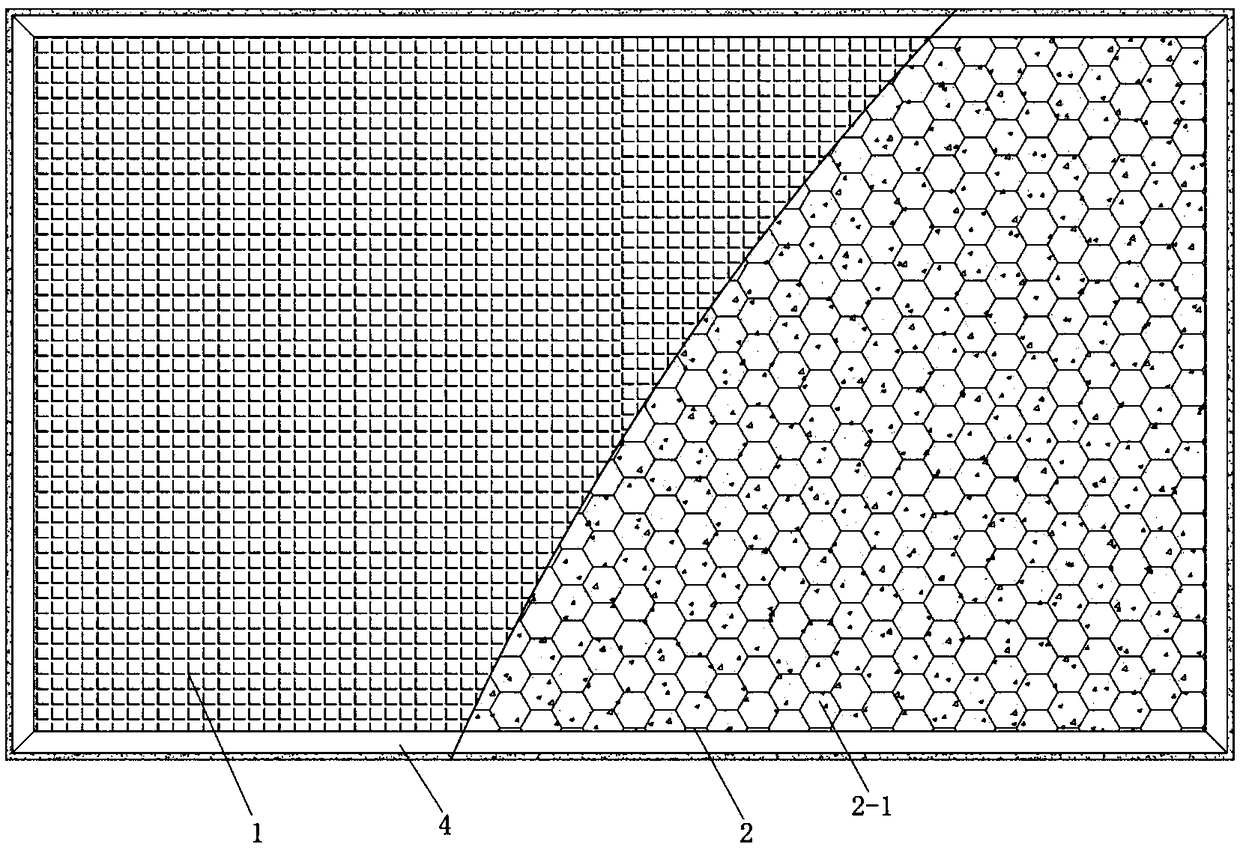

[0059] To the 6L porous large carrier porous PU sponge surface (thickness is 15mm, the volume ratio of small carrier and porous large carrier is 2: 3) evenly spray self-adhesive on the inner wall of large carrier mesh, film thickness 0.1-0.2mm, the gained The small carrier loaded with guanine is bonded and fixed on the surface of the porous large carrier mesh, and then the primary effect PET non-woven mesh (thickness is 0.3mm) is respectively fixed on the windward side and the windward side to ensure that both sides are even and smooth, and hot melt adhesive is used around the Seal and fix the corrugated paper frame to obtain th...

Embodiment 2

[0061] 4L of coal-based carbon particle carrier (50-70 mesh, specific surface area of 1500m 2 / g) Soak in 2000g mass concentration of 15% guanine aqueous solution, the soaking temperature is 50 DEG C, the time is 3 hours, then remove the moisture by suction filtration, and bake at 100 DEG C for 2 hours to obtain the small carrier loaded with guanine .

[0062] To the surface of the 4.3L porous large carrier porous PET plastic honeycomb (thickness is 12mm, the volume ratio of the small carrier to the porous large carrier is 2.8:3) evenly spray self-adhesive on the inner wall of the large carrier mesh, the film thickness is 0.1-0.2mm, The obtained small carrier loaded with guanine is bonded and fixed on the surface of the porous large carrier mesh, and then the primary effect glass fiber mesh cloth (thickness is 0.4mm) is respectively fixed on the windward side and the windward side to ensure that the surface is even and smooth, and that both sides are even It is flat, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com