Car body part stamped by intelligent equipment and forming compound die of car body part

A forming mold and compound mold technology, which is applied to vehicle parts, forming tools, and ejection equipment, can solve the problems of not showing a more rational idea, lower processing accuracy, and clumsy large-scale equipment, so as to improve production efficiency and production capacity And the effect of improving production quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

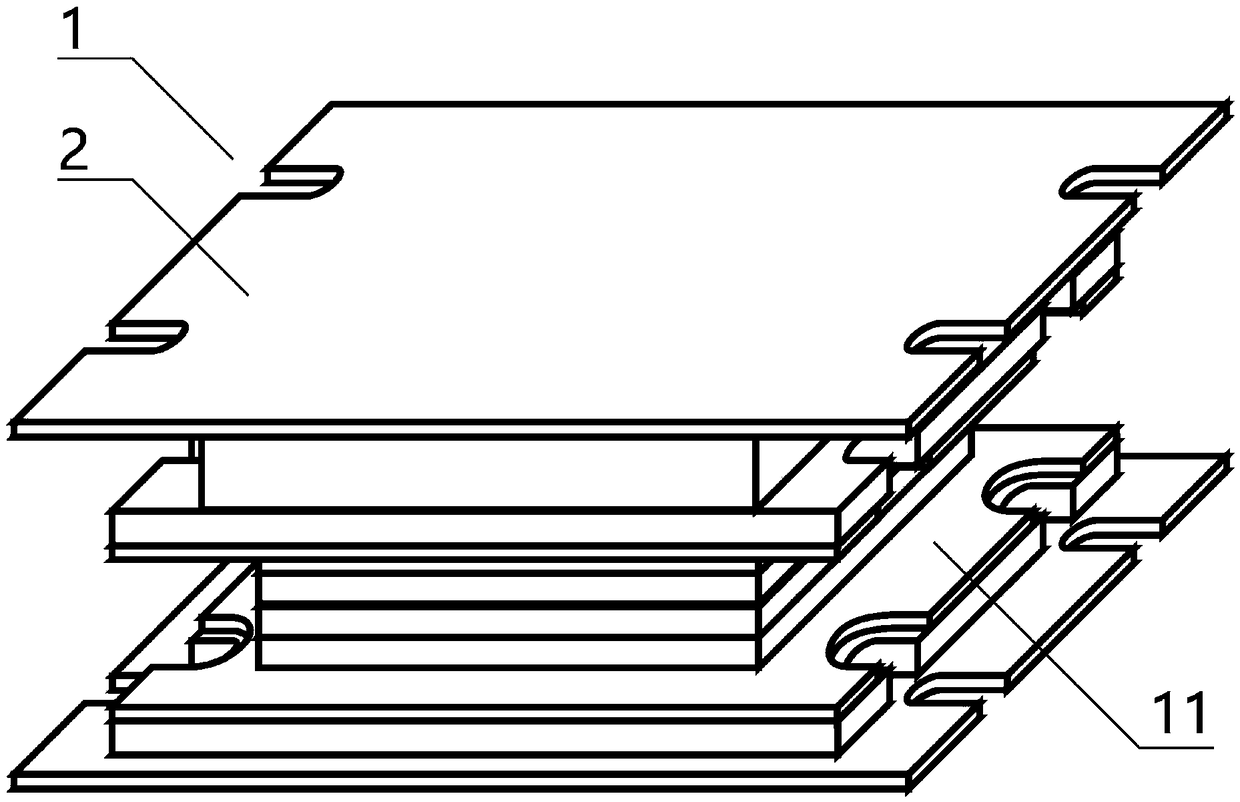

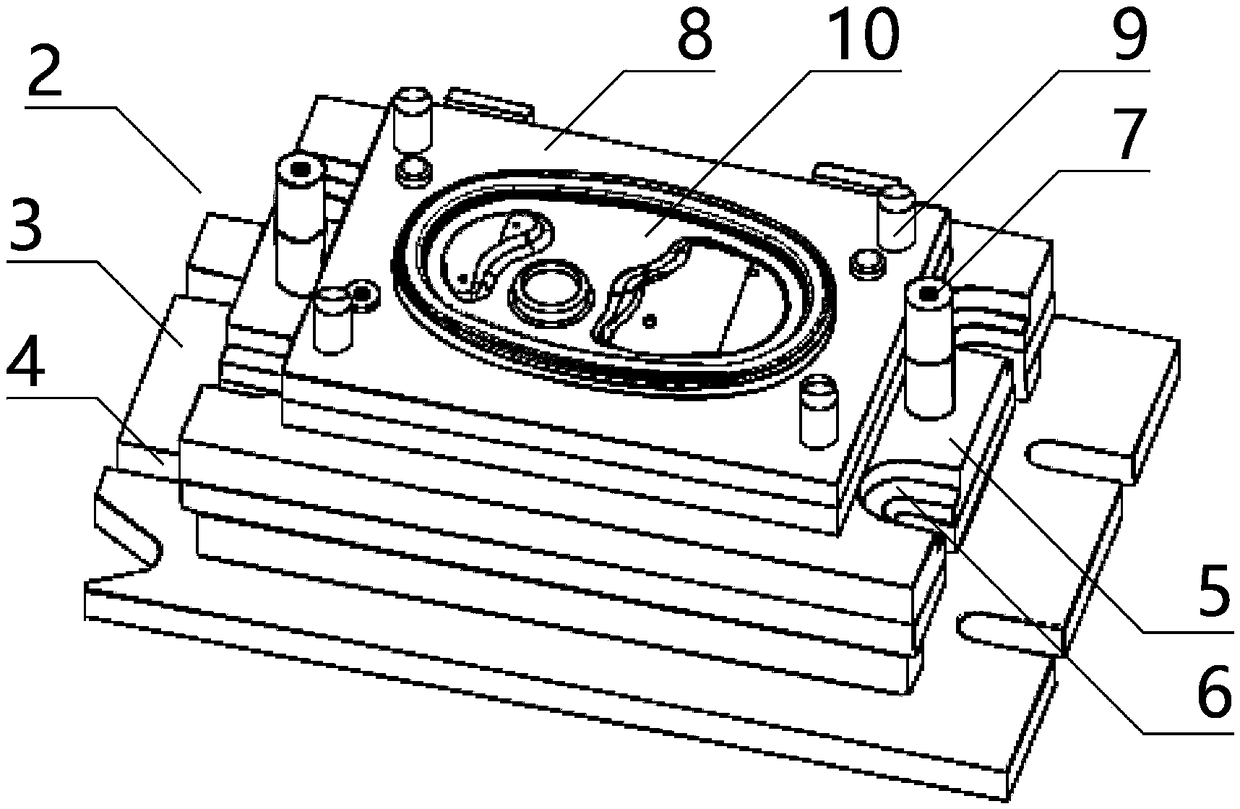

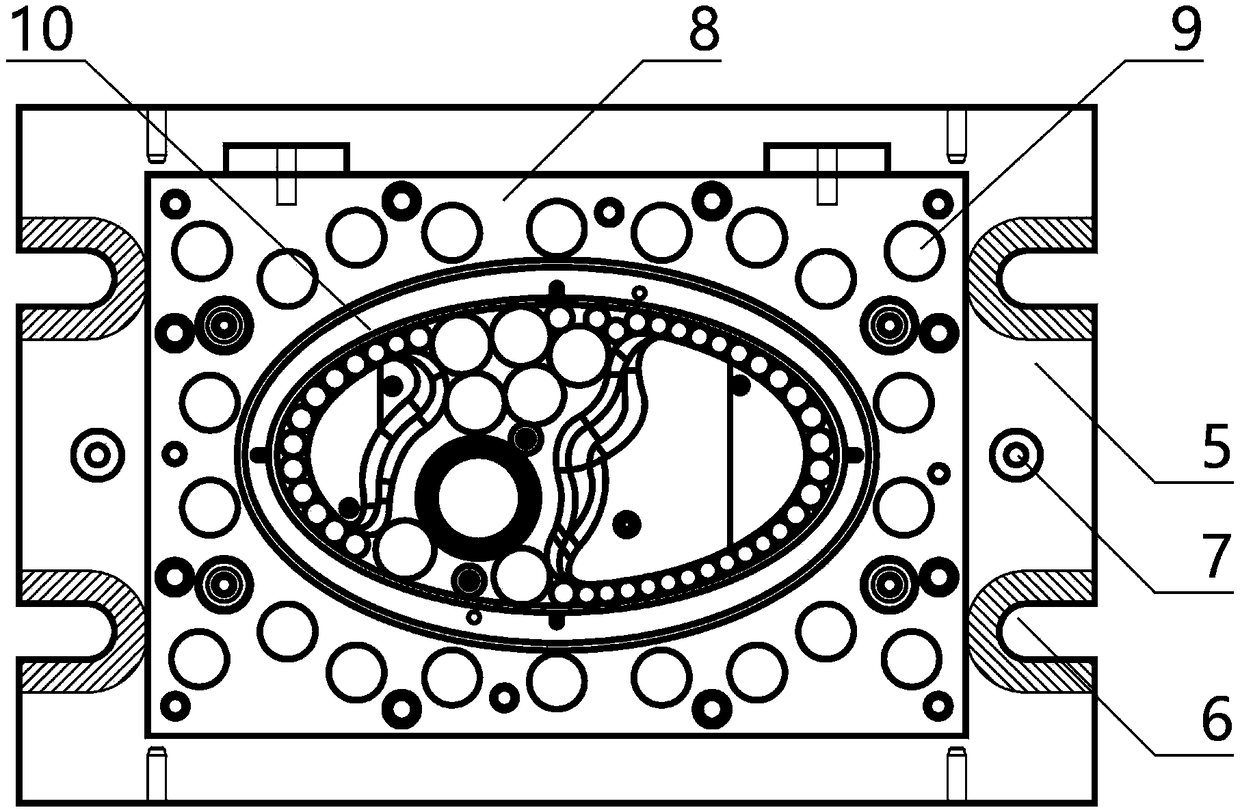

[0048] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13Shown is a car body part stamped by intelligent equipment and its molding composite mold, including a molding composite mold 1, a component body 20 and an intelligent stamping mechanism 25, and the molding composite mold 1 is installed in the intelligent stamping mechanism 25, The forming composite mold 1 is fixedly connected with the intelligent stamping mechanism 25, and the component body 20 is formed by punching and clamping the forming composite mold 1, and the forming composite mold 1 includes the upper forming mold 2 and the vehicle body Parts lower molding die 11, the upper molding die 2 of the car body part is composed of the upper molding die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com