Laser cladding additive forming online monitoring device and look-ahead-feedback control method

A feedback control, laser cladding technology, applied in the fields of laser cladding and laser additive manufacturing, laser cladding additive forming online monitoring device and forward-feedback control, can solve the problem of online mismatch of process parameters, and achieve computing The effect of high speed, reduction of forming defects, and stable melt-solidification state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

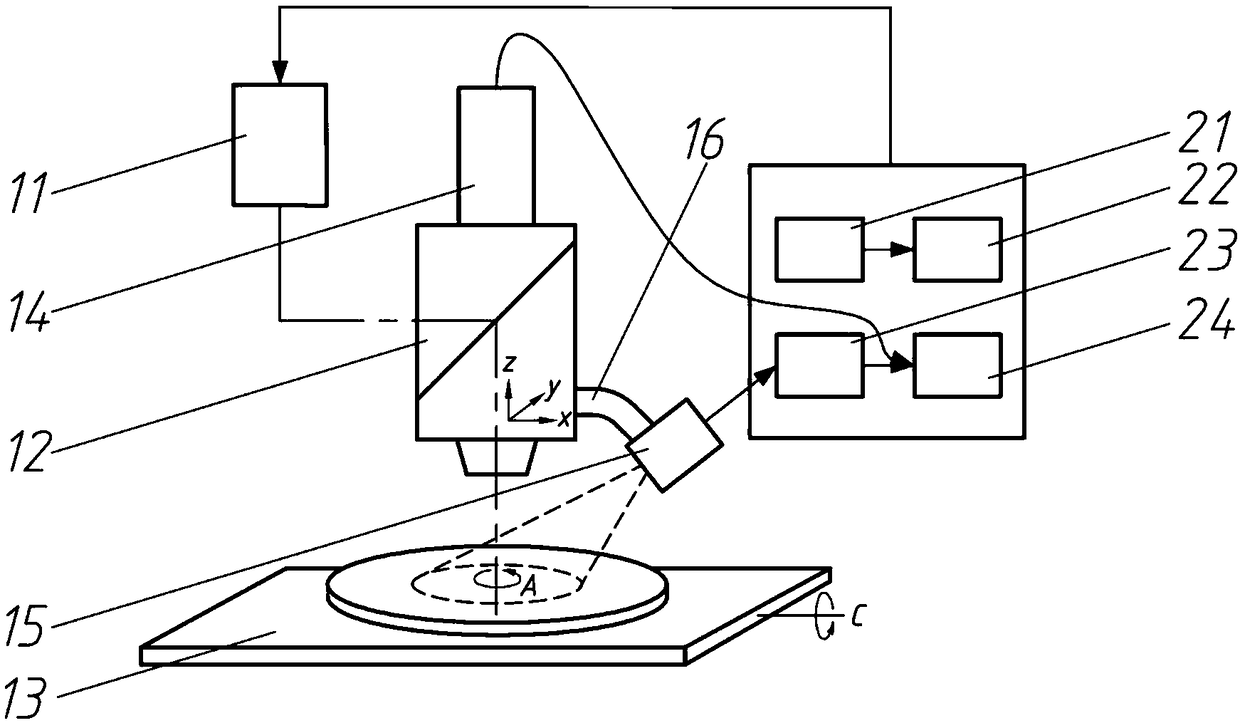

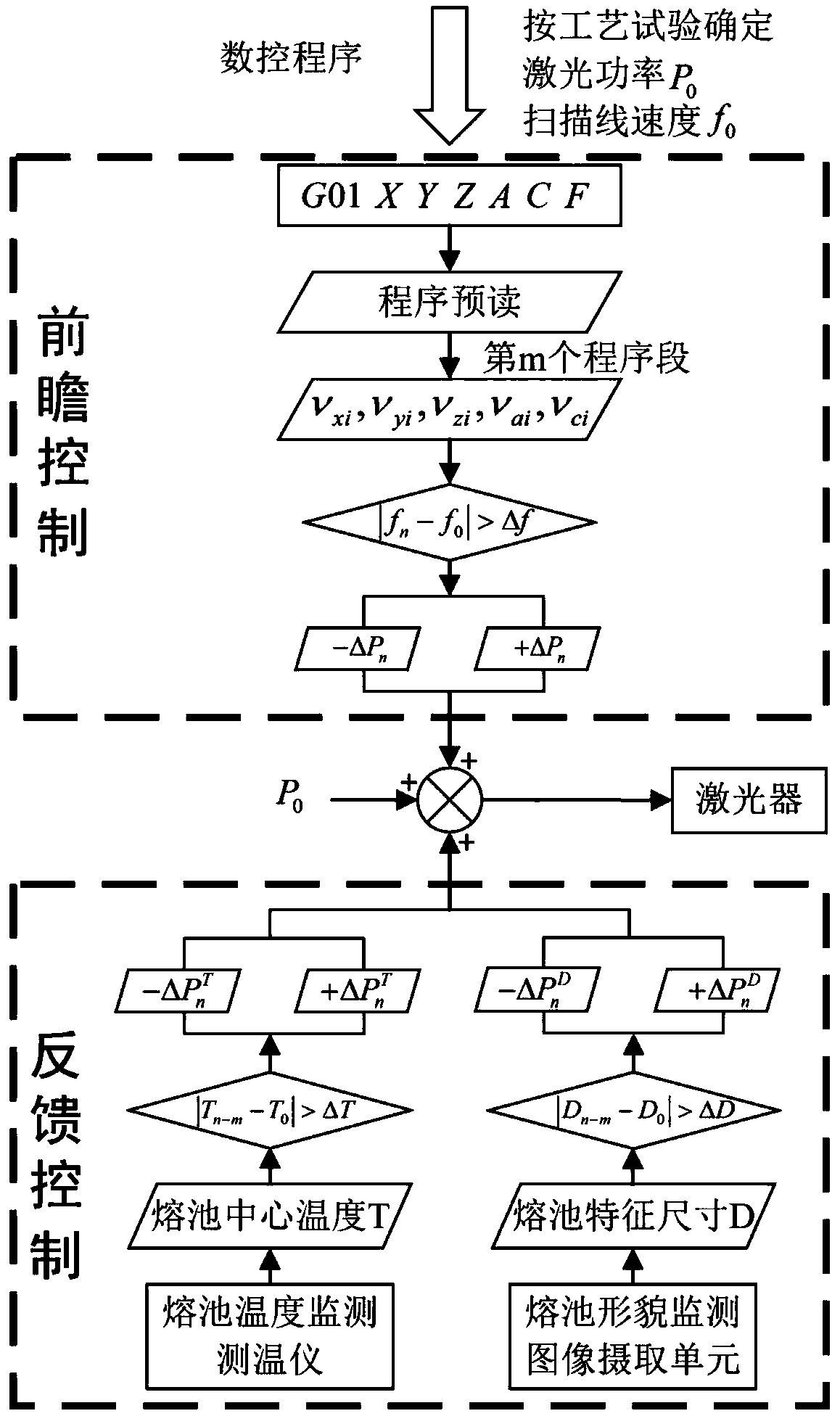

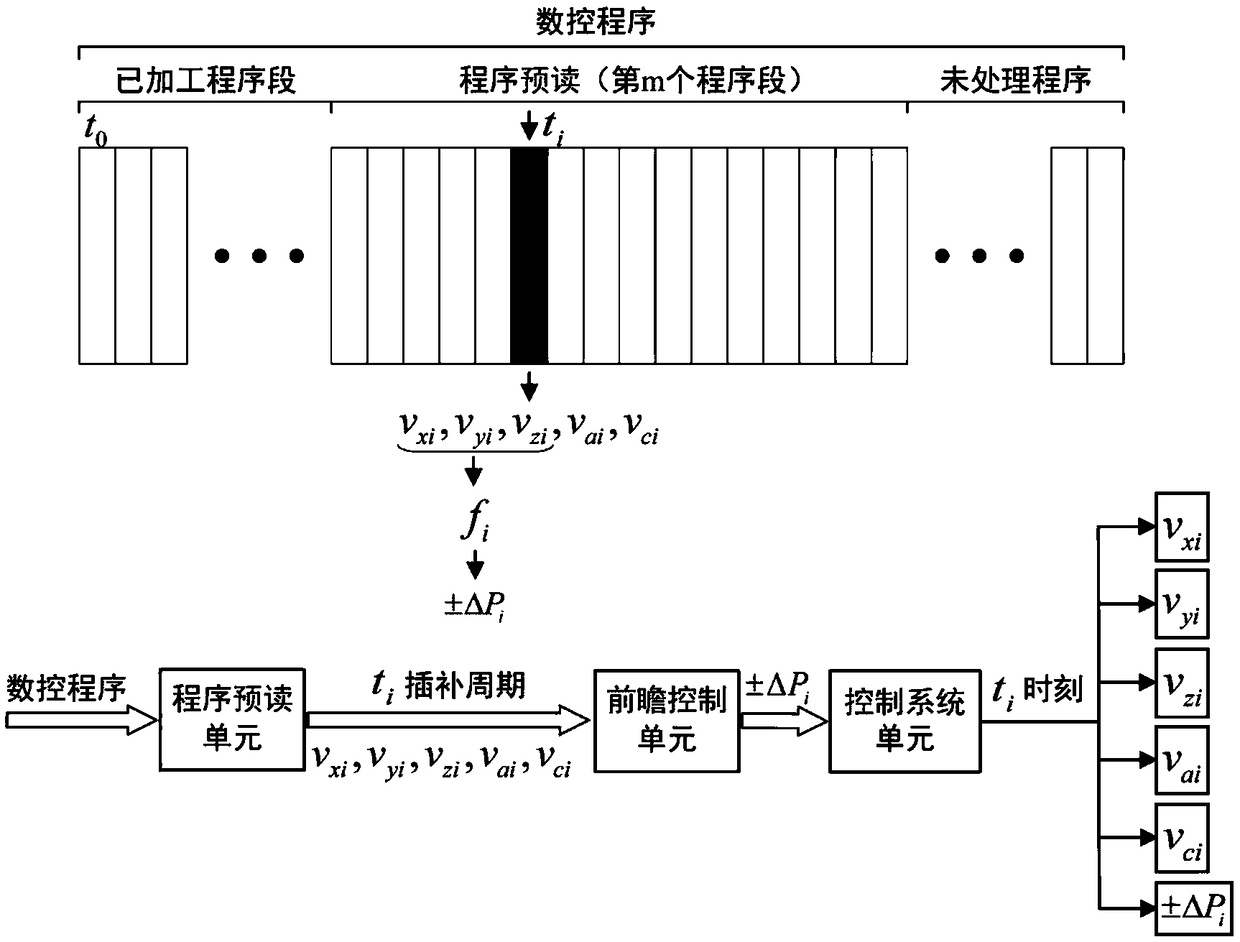

[0042] See figure 1 , figure 1 It is a schematic diagram of the online monitoring device for laser cladding and additive forming of the present invention. The online monitoring device for laser cladding additive forming is used in laser rapid manufacturing process, including laser 11, cladding head 12, workbench 13, temperature measuring instrument 14, image capture unit 15, connecting frame 16 and control system unit. A laser beam generated by the laser 11 is respectively reflected, collimated and converged to the laser processing area. The cladding head 12 is integrated in a five-axis CNC machining center (not shown in the figure), and can move in three directions: x, y, and z. The workbench 13 is composed of a turntable and a cradle that rotate around the z-axis and the x-axis respectively, and realizes five-axis linkage with the cladding head 12 that can move in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com