Preparation method of novel hydrophobic oleophilic resin

A hydrophobic and lipophilic, new type of technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve problems that limit practical applications, and achieve the effect of high-efficiency adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

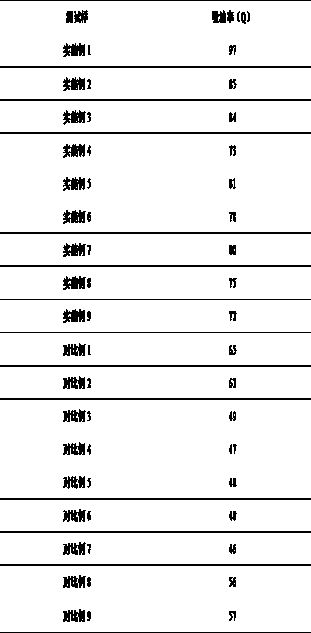

Examples

Embodiment 1

[0010] 1) Weigh 5 parts by weight of serpentine powder and add it to 300 parts by weight of deionized water, stir magnetically for 24 hours at 150rmp to obtain a stable suspension of serpentine; weigh 0.18 parts by weight of cetyltrimethyl Ammonium bromide, add the deionized water of 60 weight parts, continue stirring and dissolving 30min, make cetyltrimethylammonium bromide aqueous solution, finally this cetyltrimethylammonium bromide aqueous solution that will make is added Add 0.5 parts by weight of sodium dodecylbenzenesulfonate to the chrysotile suspension, react at 80°C for 3 hours, then use a high-speed emulsifying disperser to disperse at a speed of 6000r / min for 60 minutes, and then mix the obtained slurry Centrifuge at a speed of 3000r / min for 5min, take the precipitate and wash it three times with 100 parts by weight of methanol with a concentration of 30% and 100 parts by weight of deionized water to remove unreacted substances, and dry at 80°C for 24 h to prepare ...

Embodiment 2

[0016] It is exactly the same as Example 1, except that 10 parts by weight of new platinum nanoparticles and 52 parts by weight of organic chrysotile are added.

Embodiment 3

[0018] It is exactly the same as Example 1, except that 16 parts by weight of new platinum nanoparticles and 46 parts by weight of organic chrysotile are added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com