Waterproof heat-insulating material and preparation method thereof

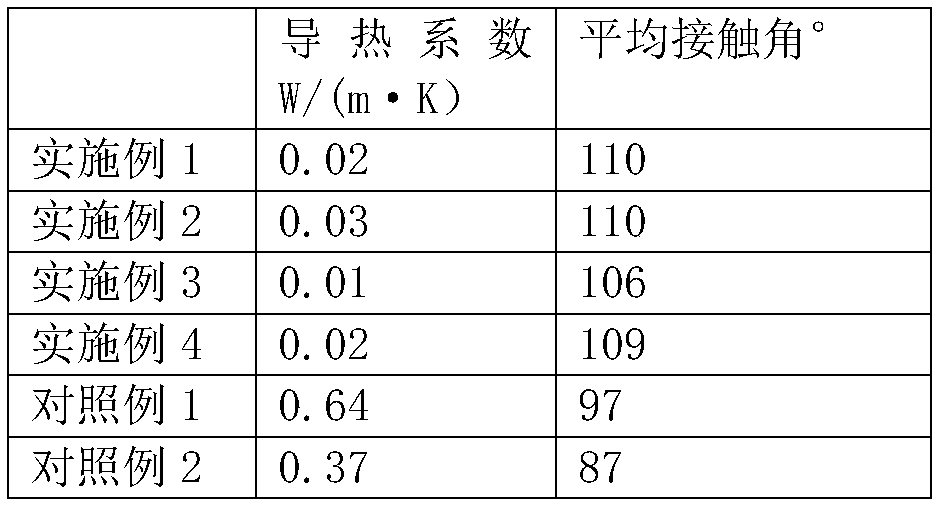

A technology of thermal insulation materials and raw materials, applied in the field of materials, can solve the problems of non-waterproof insulation materials, and achieve the effects of improving the average contact angle, good waterproof effect, and good thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The waterproof and heat-insulating material includes the following raw materials in parts by weight: 70 parts of tetraphenylresorcinol diphosphate, 60 parts of polytetrafluoroethylene, 50 parts of pentaerythritol phosphate, 20 parts of dimethyl phthalate, three 50 parts of methylethylenediamine, 40 parts of glass fiber, 45 parts of polyurethane methacrylic resin, 5 parts of methacrylic acid, 7 parts of cumene hydroperoxide.

[0019] The preparation method of the waterproof and heat-insulating material comprises the following steps: mixing tetraphenylresorcinol diphosphate, pentaerythritol phosphate, and dimethyl phthalate, and stirring evenly; adding glass fibers while stirring, and raising the temperature to 80 ~100°C, add polyurethane methacrylic resin, methacrylic acid, keep warm for 2~3h; cool down to 40~60°C, add polytetrafluoroethylene, cumene hydroperoxide, trimethylethylenediamine, mix well ; Inject into the heat insulation layer.

Embodiment 2

[0021] The waterproof and heat-insulating material includes the following raw materials in parts by weight: 40 parts of tetraphenylresorcinol diphosphate, 40 parts of polytetrafluoroethylene, 20 parts of pentaerythritol phosphate, 10 parts of dimethyl phthalate, three 40 parts of methylethylenediamine, 30 parts of glass fiber, 40 parts of polyurethane methacrylic resin, 4 parts of methacrylic acid, 3 parts of cumene hydroperoxide.

[0022] The preparation method of the waterproof and heat-insulating material comprises the following steps: mixing tetraphenylresorcinol diphosphate, pentaerythritol phosphate, and dimethyl phthalate, and stirring evenly; adding glass fibers while stirring, and raising the temperature to 80 ~100°C, add polyurethane methacrylic resin, methacrylic acid, keep warm for 2~3h; cool down to 40~60°C, add polytetrafluoroethylene, cumene hydroperoxide, trimethylethylenediamine, mix well ; Inject into the heat insulation layer.

Embodiment 3

[0024] The waterproof and heat-insulating material includes the following raw materials in parts by weight: 100 parts of tetraphenylresorcinol diphosphate, 80 parts of polytetrafluoroethylene, 100 parts of pentaerythritol phosphate, 30 parts of dimethyl phthalate, three 60 parts of methylethylenediamine, 50 parts of glass fiber, 50 parts of polyurethane methacrylic resin, 6 parts of methacrylic acid, 10 parts of cumene hydroperoxide.

[0025] The preparation method of the waterproof and heat-insulating material comprises the following steps: mixing tetraphenylresorcinol diphosphate, pentaerythritol phosphate, and dimethyl phthalate, and stirring evenly; adding glass fibers while stirring, and raising the temperature to 80 ~100°C, add polyurethane methacrylic resin, methacrylic acid, keep warm for 2~3h; cool down to 40~60°C, add polytetrafluoroethylene, cumene hydroperoxide, trimethylethylenediamine, mix well ; Inject into the heat insulation layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com