Electrolyte for preparing bioactive element contained porous membrane on titanium metal surface through micro-arc oxidation

A micro-arc oxidation, bioactive technology, applied in surface reaction electrolytic coatings, electrolytic coatings, coatings, etc., to achieve the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

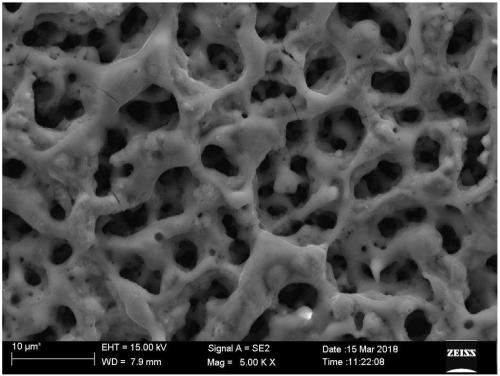

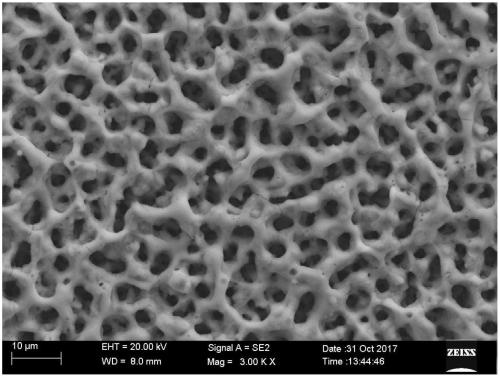

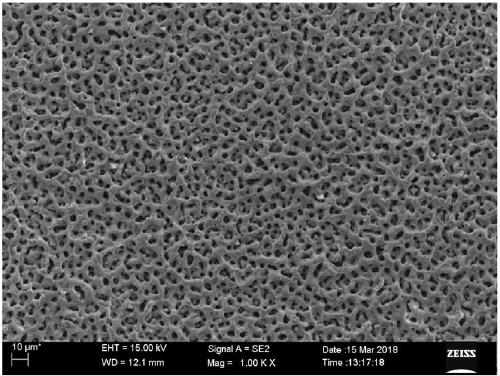

Image

Examples

Embodiment 1

[0034] Each component is weighed according to the molar concentration and mixed and stirred to form an electrolyte solution. The solvent is: deionized water; the solute is: sodium tetraborate (Na 2 B 4 o 7 10H 2 O) 0.15mol / L; suspended matter: calcium oxide (CaO) 0.05mol / L. XRD shows that the prepared micro-arc oxidation coating is mainly composed of rutile phase titanium dioxide and anatase phase titanium dioxide. EDS shows that the prepared micro-arc oxidation coating has an atomic percentage of calcium of about 2%, and the contact angle test shows that the prepared micro-arc oxidation coating The water contact angle of the coating is about 7°.

Embodiment 2

[0036] Each component is weighed according to the molar concentration and mixed and stirred to form an electrolyte solution. The solvent is: deionized water; the solute is: lithium tetraborate (Li 2 B 4 o 7 ) 0.15mol / L; suspended matter: strontium oxide (SrO) 0.05mol / L. XRD shows that the prepared micro-arc oxidation coating is mainly composed of rutile phase and anatase phase titanium dioxide, EDS shows that the prepared micro-arc oxidation coating has an atomic percentage of strontium of about 2%, and the contact angle test shows that the prepared micro-arc oxidation coating The layer water contact angle is about 6°.

Embodiment 3

[0038] Each component is weighed according to the molar concentration and mixed and stirred to form an electrolyte solution. The solvent is: deionized water; the solute is: sodium tetraborate (Na 2 B 4 o 7 10H 2 O) 0.15mol / L; suspended matter: strontium oxide (SrO) 0.025mol / L, calcium oxide (CaO) 0.025mol / L. XRD shows that the prepared micro-arc oxidation coating is mainly composed of rutile phase and anatase phase titanium dioxide. EDS shows that the prepared micro-arc oxidation coating has about 1 atomic percent of calcium element and about 1 atomic percent of strontium element. The sum of the atomic percentages of calcium and strontium is about 2%, and the contact angle test shows that the water contact angle of the prepared micro-arc oxidation coating is about 5°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com