TBM hob dynamic and static loaded-line cutting test bed

A technology of loading line and test bench, which is applied in the field of underground space engineering, can solve the problems of complex structure, deviation of processing track, inability to carry out hob rolling rock breaking test, etc., and achieve the effect of simple structure and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

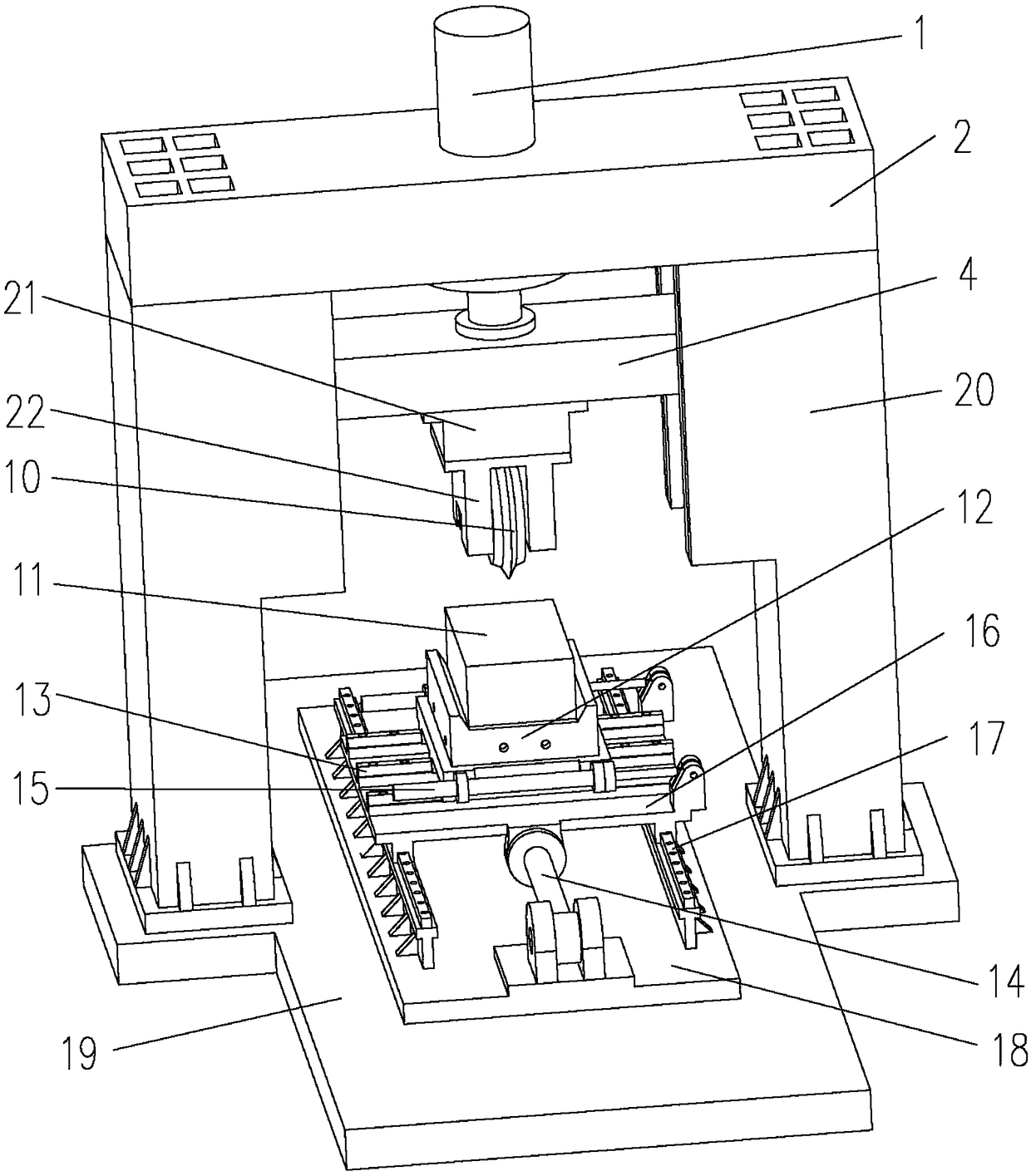

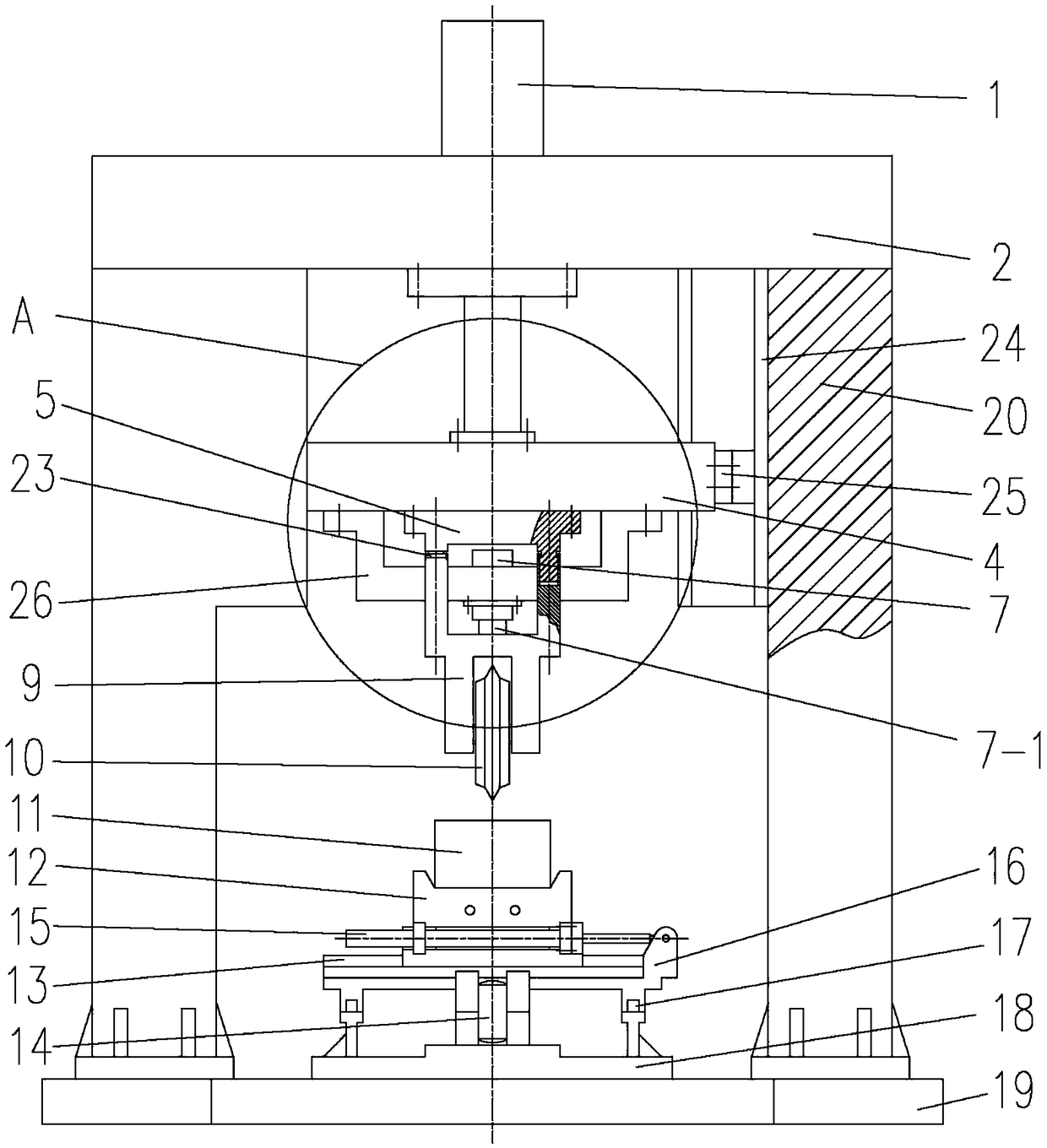

[0033] In order to solve the problem that the hob loading device of the existing TBM standard wire cutting test bench cannot carry out the rock breaking test under the condition of dynamic and static loading, the present invention provides a TBM hob dynamic and static loading line on the basis of the existing TBM standard wire cutting test bench Cutting test bench. Such as figure 2 and Figure 5 As shown, a kind of TBM hob dynamic and static loading wire cutting test bench provided by the present invention includes: vertical hydraulic cylinder (1), beam (2), vertical guide rail (24), column I (20), slide block (25 ), movable beam I (4), vibrator (7), stone bin support platform (16), longitudinal guide rail (17), stone bin support base (18), base (19), transition connection support (5 ), end cover (23), exciter mounting base (26), hob mounting base II (9), hob (10), stone bin (12), horizontal oil cylinder (15), horizontal guide rail (13 ), longitudinal oil cylinder (14), it...

specific Embodiment 2

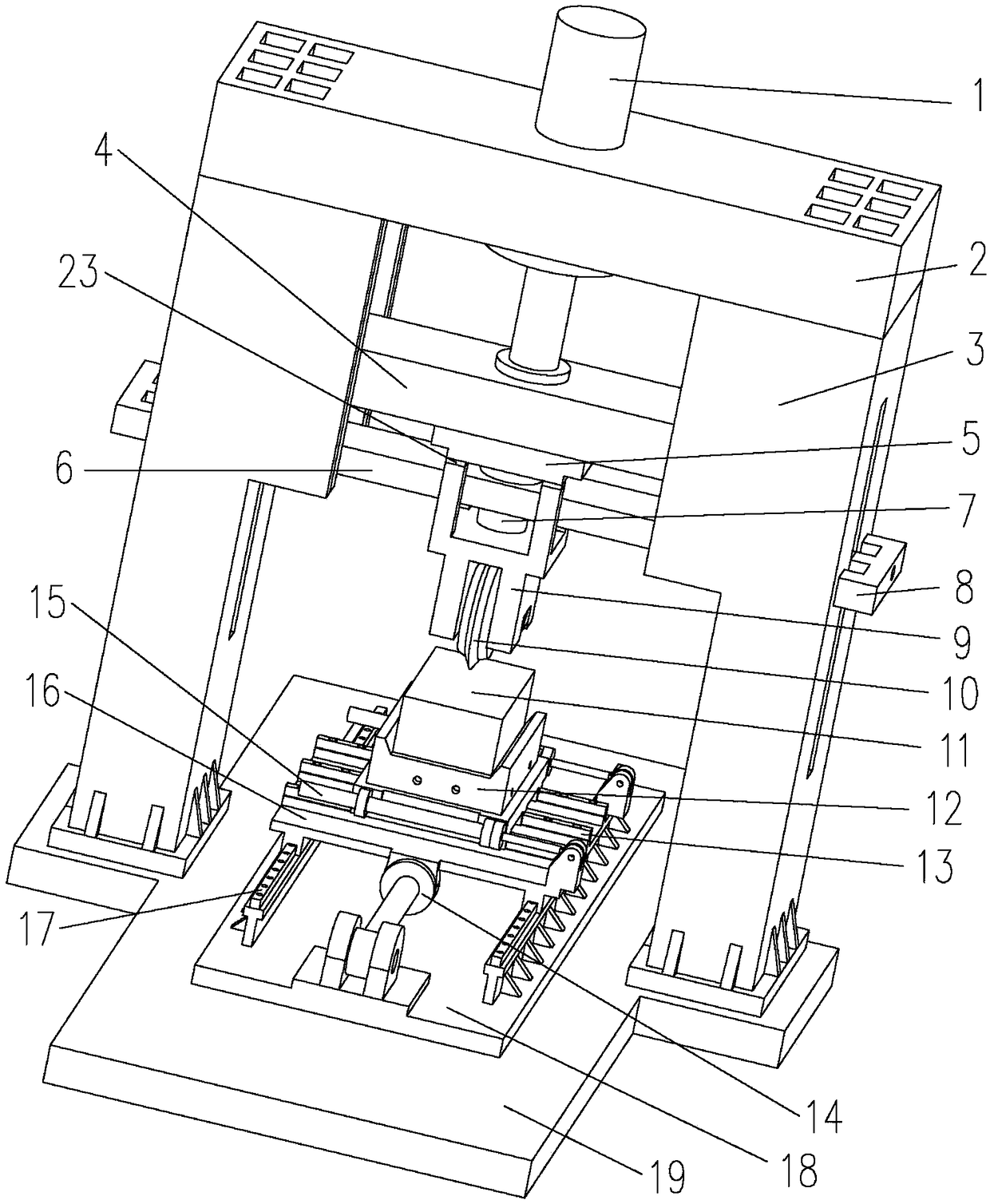

[0046] In order to avoid the excitation reaction force from being transmitted to the vertical hydraulic cylinder (1) when the exciter (7) is working, as a preference, as image 3 , Figure 4 and Figure 6 As shown, the exciter mount (26) fixedly connected to the movable beam I (4) is replaced with the movable beam II (6); a guide groove is provided on the column II (3) to obtain the column II (3); the movable beam II (6) horizontally passes through the gap between the transition connection support (5) and the hob installation seat II (9), and the two ends of the movable beam II (6) are vertically and movable embedded in the guide groove; The relative position of the movable crossbeam II (6) relative to the guide groove can be adjusted; in this example, more specifically, the two ends of the movable crossbeam II (6) pass through the guide groove and then are respectively fixed with the movable crossbeam fixing bolts (8). Connect; the movable crossbeam fixing bolt (8) is provi...

specific Embodiment 1

[0049] Comparative analysis of specific embodiment one and specific embodiment two can know:

[0050] 1) Compared with the existing TBM standard wire-cutting test bench, the specific embodiment 1 has less changes, and the cost of equipment modification is lower, but the excitation reaction force is transmitted to the vertical hydraulic cylinder (1) when the vibrator (7) is working;

[0051] 2) Compared with the existing TBM standard wire-cutting test bench, the specific embodiment 2 has a large change (for example, a guide groove is processed on the column I (20) to obtain the column II (3)), and the cost of equipment modification is relatively high, but the vibration exciter (7) The excitation reaction force will not be transmitted to the vertical hydraulic cylinder (1) during operation;

[0052] In addition, the movable crossbeam II (6) is limited on the column II (3) only by means of set screws, which has poor reliability and is difficult to adjust (time-consuming and labor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com