A method for predicting performance degradation of thin-film thermal control coatings under near-ultraviolet radiation

A technology of thermal control coating and prediction method, which is applied in the field of space environment engineering, can solve the problems of increasing solar absorption ratio and reducing optical performance, etc., and achieve the effect of improving test efficiency and saving test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

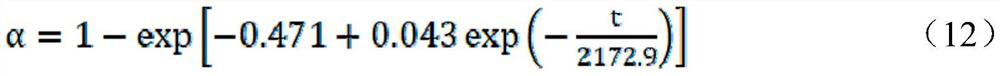

[0041]A method for predicting the performance degradation of a thin film thermal control coating under near ultraviolet radiation, specifically a method for predicting the change of the solar absorption ratio α of the thin film thermal control coating under near ultraviolet radiation with the near ultraviolet radiation amount t (ESH).

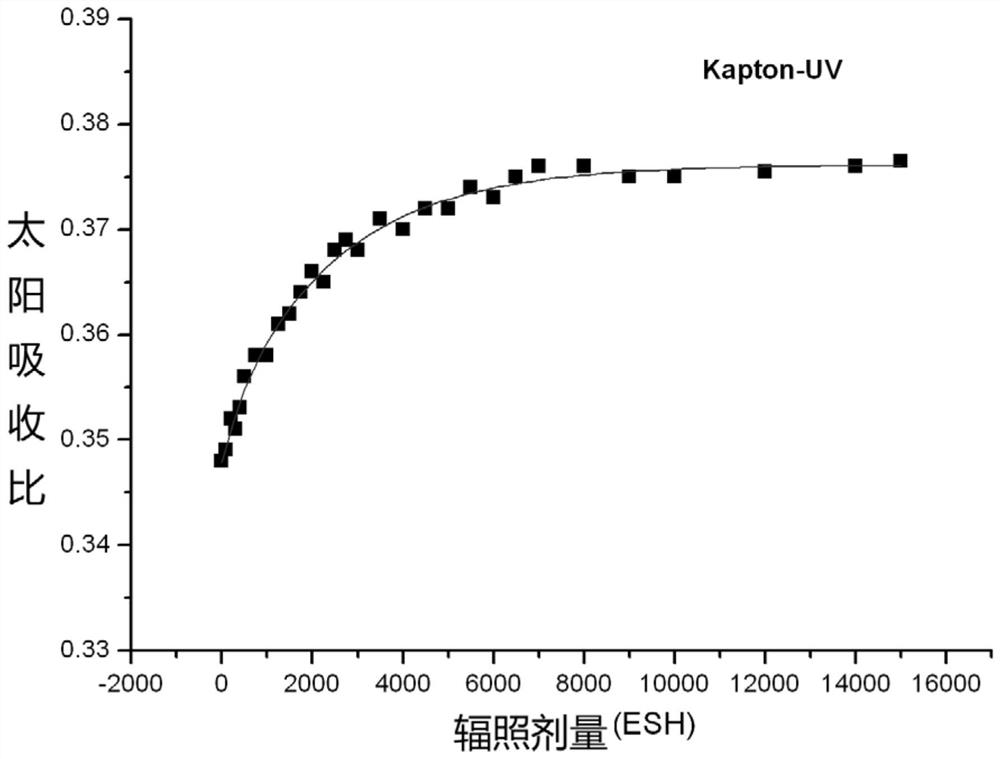

[0042]A near-ultraviolet radiation test was carried out for aluminized polyimide film. The radiation source was a mercury-xenon lamp, the acceleration factor was 4 to 5 times, and the total radiation was 15000ESH. This is to obtain the difference between the solar absorption ratio of the material and the near ultraviolet radiation. Change relationship, in the experiment, set multiple test points, including 0, 100, 200, 300, 400, 500, 750, 1000, 1250, 1500, 1750, 2000, 2250, 2500, 2750, 3000, 3500, 4000, 4500, 5000, 5500, 6000, 6500, 7000, 8000, 9000, 10000, 12000, 14000 and 15000 (all units are ESH).figure 2 It is a graph of the relationship between sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com