Preparation method and tooling of photoresist microstructure of large-aperture thin-film diffractive lens

A technology of diffractive lens and photoresist, which is applied in microlithography exposure equipment, photoplate making process of patterned surface, optomechanical equipment, etc. It can solve the problems that imaging cannot be realized, and it is difficult to obtain wave aberration that meets imaging requirements. , to achieve the effect of high-resolution optical imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

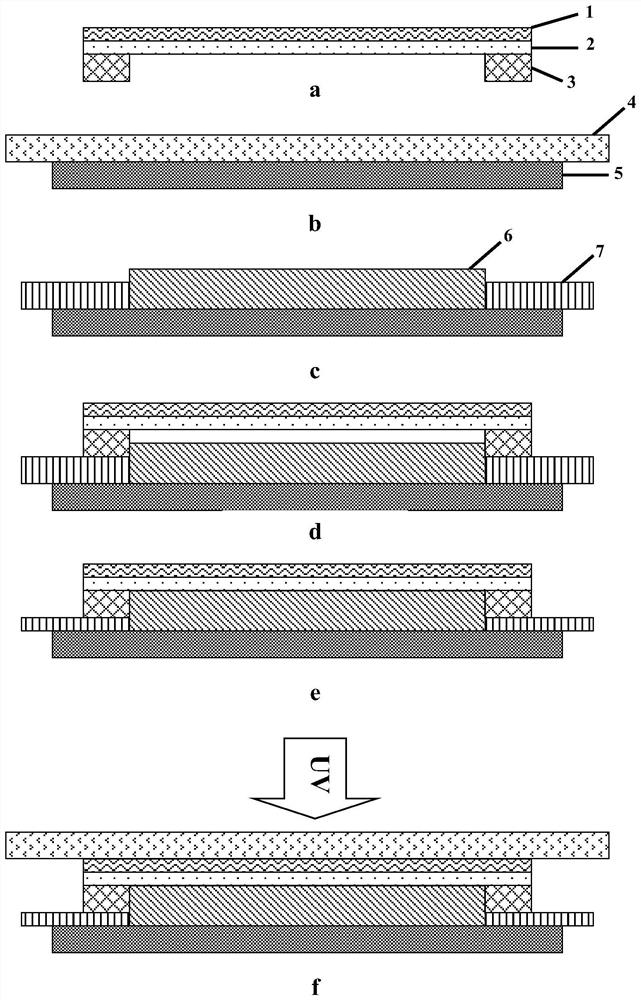

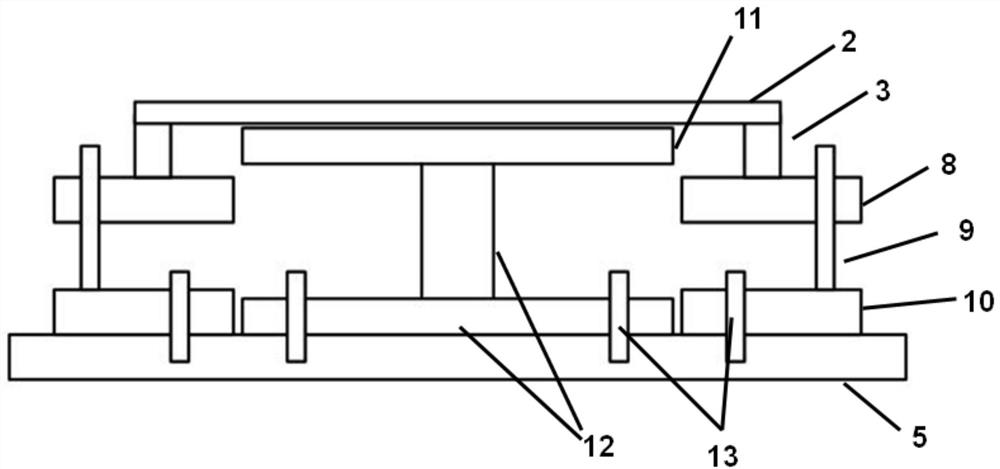

[0032] The present invention takes the preparation of photoresist microstructure of polyimide film diffractive lens with 400 mm aperture as an example, combined with the schematic diagram of the preparation method of photoresist microstructure of large aperture film diffractive lens figure 1 of figure 1 a- figure 1 f, The principle and process steps of the preparation method of the photoresist microstructure of the large-aperture thin-film diffractive lens in detail. in, figure 1 a is a schematic diagram of the coating process steps of the method for preparing the photoresist microstructure of the large-aperture thin-film diffractive lens; figure 1 b is a schematic diagram of the datum plane leveling process steps of the method for preparing the photoresist microstructure of the large-aperture thin film diffractive lens; figure 1 c is a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com