Fiber-reinforced foam sandwich structure radome and making method

A technology of radome and sandwich structure, applied in the field of radome, can solve the problems of impact resistance, bending resistance, buckling resistance, and poor delamination resistance performance, so as to improve shear strength, impact resistance, and flat pressure. Effects of Strength and Modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

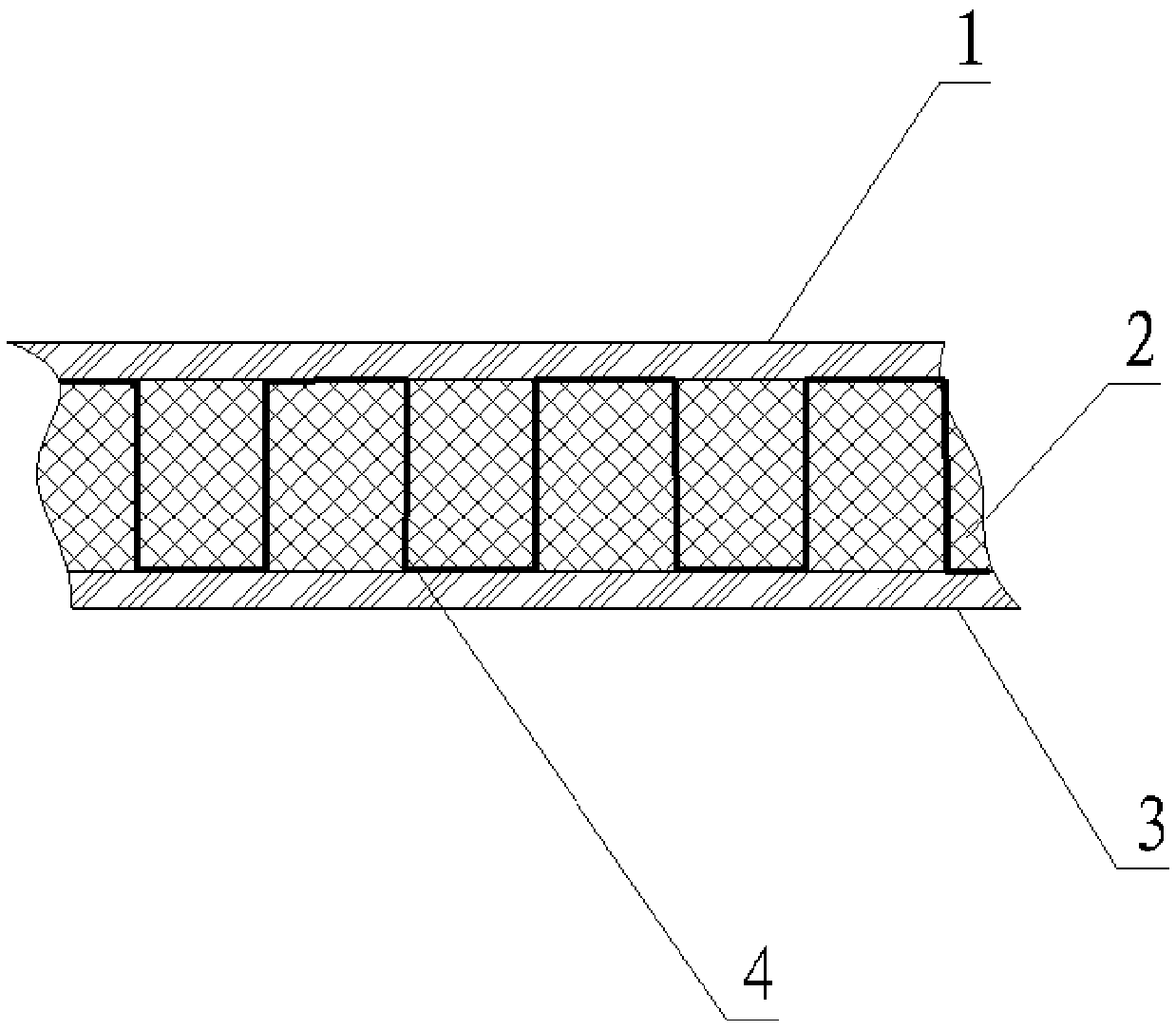

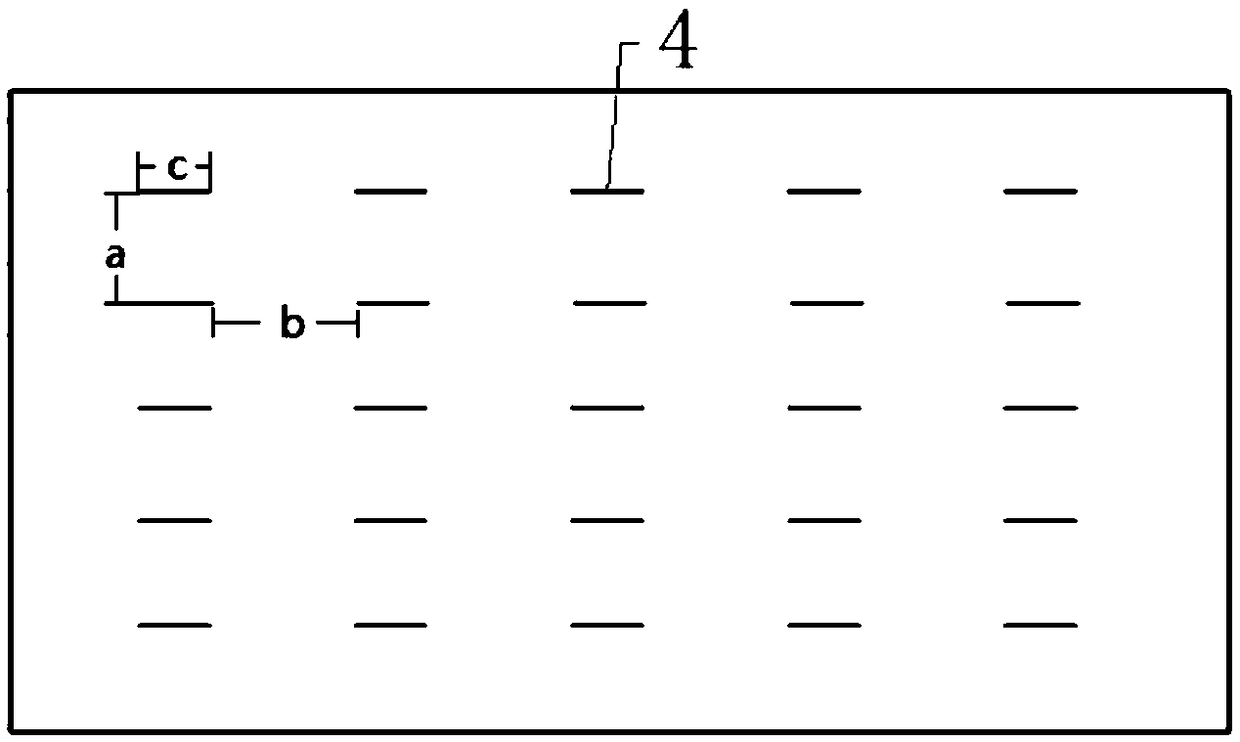

[0020] Below in conjunction with accompanying drawing, the present invention will be further introduced, as figure 1 and figure 2 As shown, a fiber-reinforced foam sandwich structure radome comprises an upper skin 1, a lower skin 3 and a foam interlayer 2, and the upper skin 1 and the lower skin 3 are laid on the upper and lower surfaces of the foam interlayer 2 respectively, There are several Kevlar fiber sutures 4 sewn along the thickness direction inside the foam interlayer 2 .

[0021] The sewing line spacing a of the Kevlar fiber suture 4 is 2 mm, the sewing needle pitch b is 20 mm, the sewing length of the Kevlar fiber suture 4 on the surface of the upper skin 1 and the lower skin 3 is 20 mm, and the sewing line spacing a is The length design of , sewing needle distance b, and suture length c can not only effectively transmit the load in the foam interlayer 2 , but also meet the wave transmission requirement of the foam interlayer 2 .

[0022] The Kevlar fiber suture ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap