Dried mulberry fruit and preparation method thereof

A mulberry fruit and drying technology, which is applied in food drying, food ingredients containing natural extracts, food extraction, etc., can solve the problems of inconvenient transportation, difficult preservation of mulberry fruit, and restrictions on large-scale planting and development, and achieve resource saving and product color. Good, high product yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

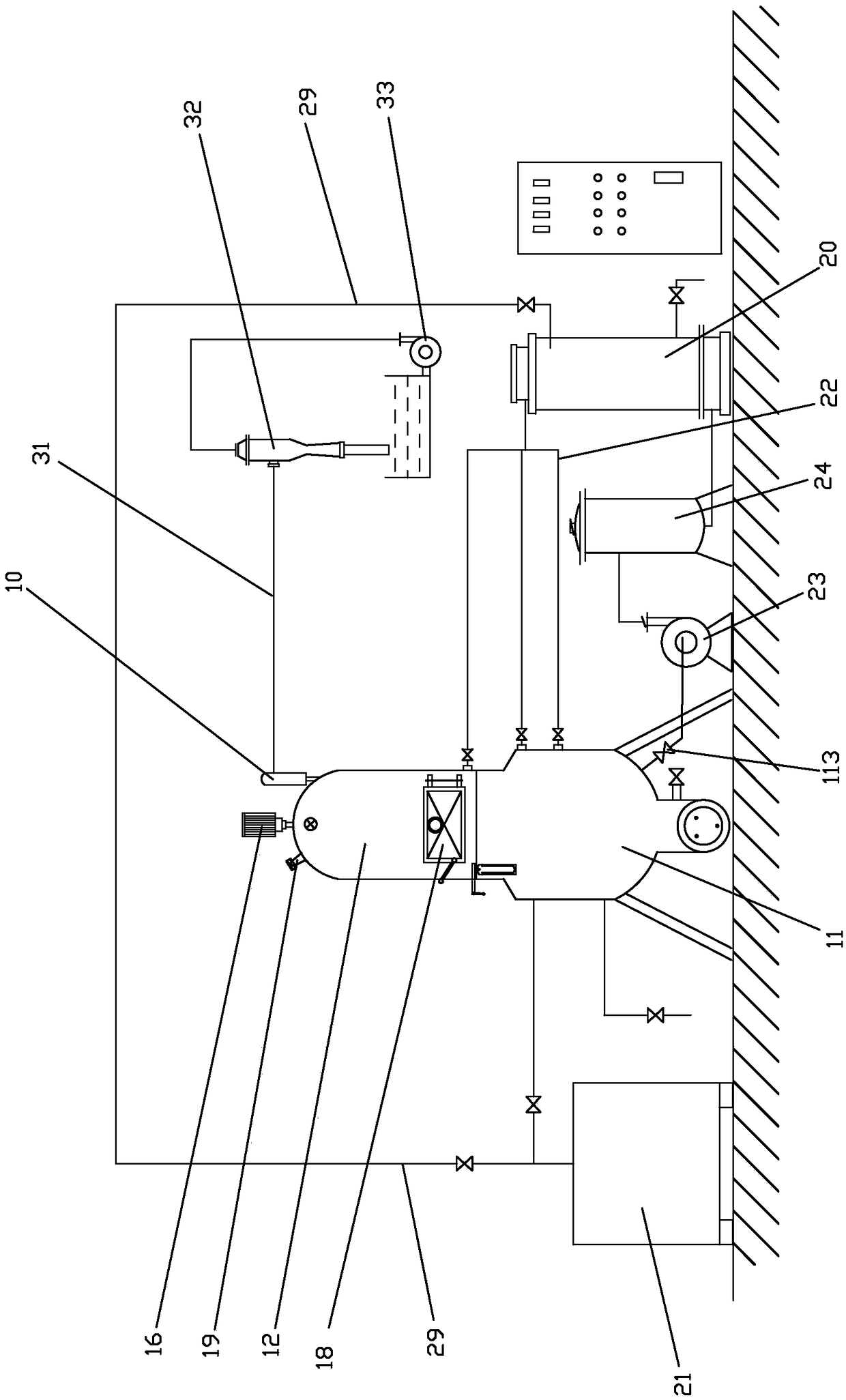

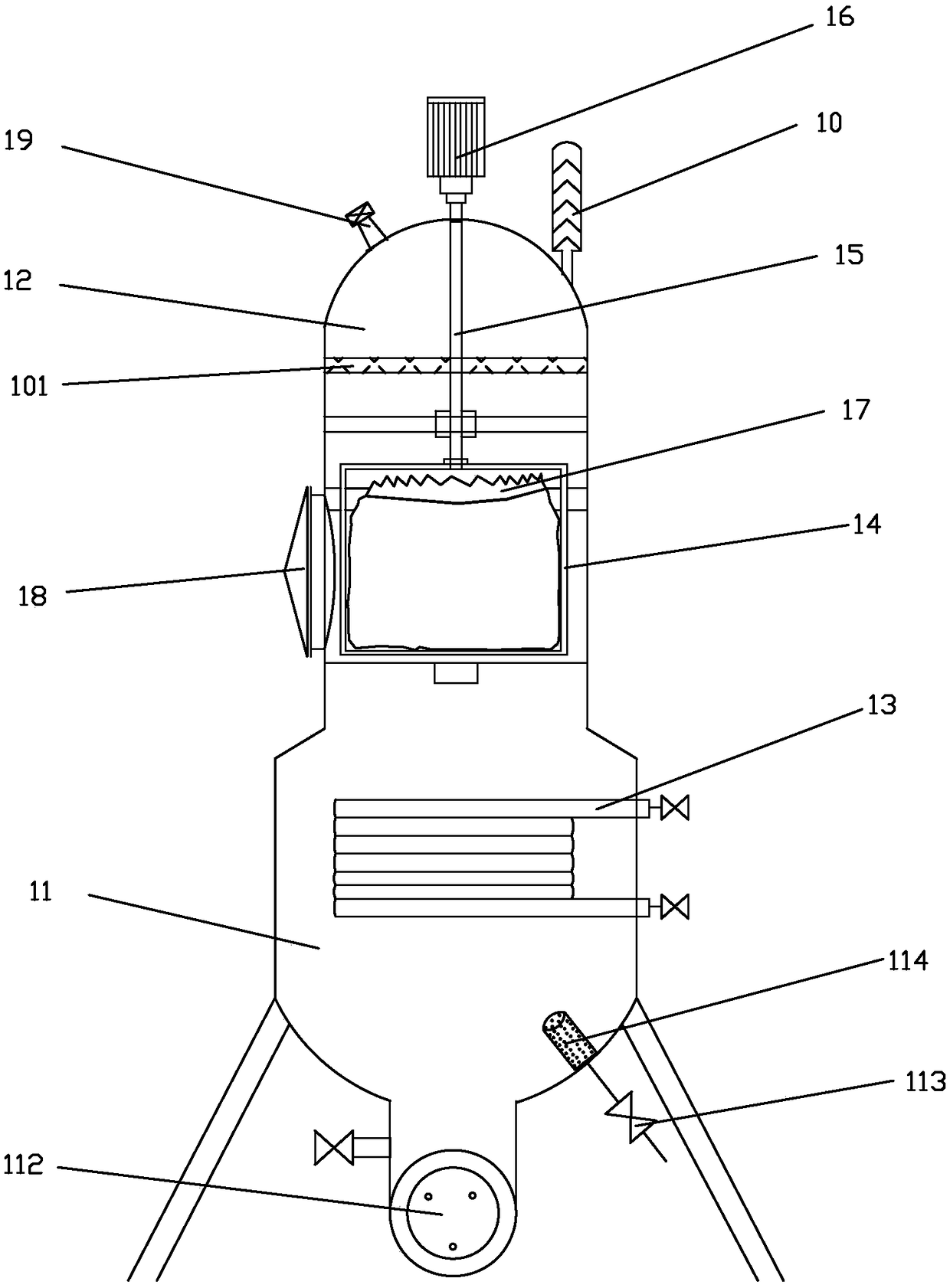

[0025] A preparation method of dried mulberry fruit, comprising the following steps:

[0026] (1) Raw material processing: put mulberries into the extraction tank;

[0027] (2) Ethanol extraction: use 30-70% ethanol to heat and reflux the cinnamon powder residue in step (1) to extract twice, merge twice to extract the medicinal liquid, and obtain the ethanol extract;

[0028] (3) Solid-liquid separation: filter the ethanol extract in the separation step (2) to obtain the ethanol extract clear liquid;

[0029] (4) Concentration: after the ethanol extraction clear liquid in the step (3) is reclaimed under reduced pressure to ethanol, concentrate to obtain a thick extract;

[0030] (5) Spray drying: the thick extract in step (4) is obtained by spray drying;

[0031] (6) Packaging: the extract is vacuum-packed to obtain dried mulberries.

Embodiment 1

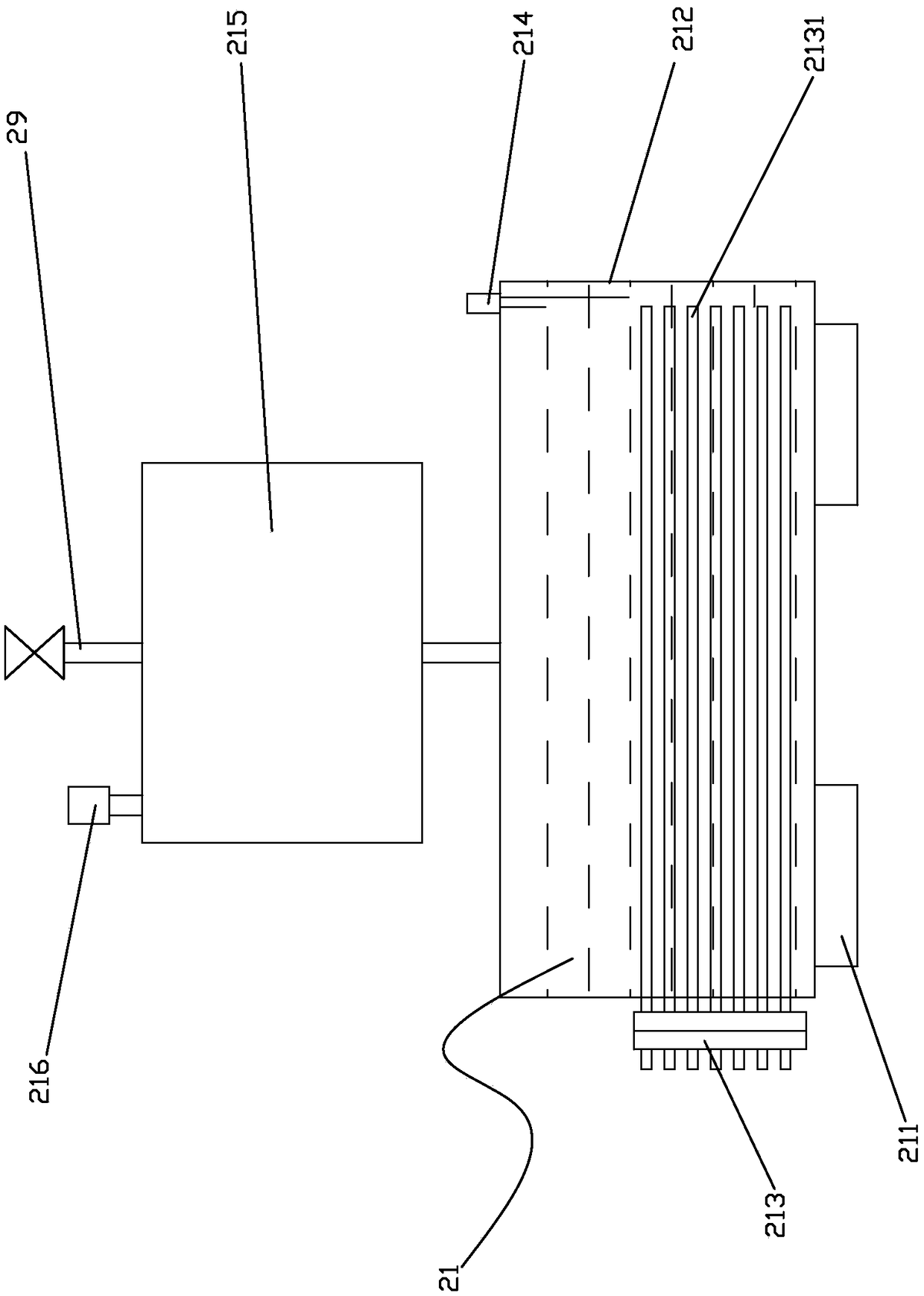

[0033] The preparation method of the dried mulberry fruit of this specific embodiment: take 10 kilograms of cassia bark powder, add 5 times the amount of 70% ethanol to reflux and extract 2 times, each time for 2 hours, the extraction temperature is 45 ° C, and the extract is filtered through a 30-mesh filter bag through a pump. Ethanol extracts the supernatant, extracts the supernatant at a temperature of 65°C, and recovers the ethanol under reduced pressure at a vacuum of 0.06MPa, then concentrates it to a thick extract with a specific gravity of 15 Pomi degrees (measured at 50°C); spray the thick extract Drying, spraying with air inlet temperature of 170°C and air outlet temperature of 70°C to obtain 1.0 kg of extract; pulverizing the extract, passing through an 80-mesh sieve, mixing, and packaging, to obtain the dried mulberry fruit yield of 12.0%, The color and flavor are good.

Embodiment 2

[0035] The preparation method of the dried mulberry fruit of this specific example: take 10 kilograms of cassia bark powder, add 8 times the amount of 50% ethanol to reflux and extract 2 times, each time for 3 hours, the extraction temperature is 65 ° C, and the extract is filtered through a 30-mesh filter bag through pumping to obtain Ethanol extracts the supernatant, extracts the supernatant at a temperature of 65°C, and recovers the ethanol under reduced pressure at a vacuum of 0.08MPa, then concentrates it to a thick extract with a specific gravity of 20 Pomi degrees (measured at 50°C); spray the thick extract Drying, spraying with air inlet temperature of 180°C and air outlet temperature of 75°C to obtain 1.5 kg of extract; pulverizing the extract, passing through an 80-mesh sieve, mixing, and packaging, to obtain the dried mulberry fruit yield of 15.0%, The color and flavor are good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com