Straw fiber extracting technology

An extraction process and straw fiber technology, applied in the field of straw fiber extraction process, can solve the problems of high cost, can not be reused, and generate a large amount of waste liquid, and achieve the effect of reducing dosage and realizing no waste liquid discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

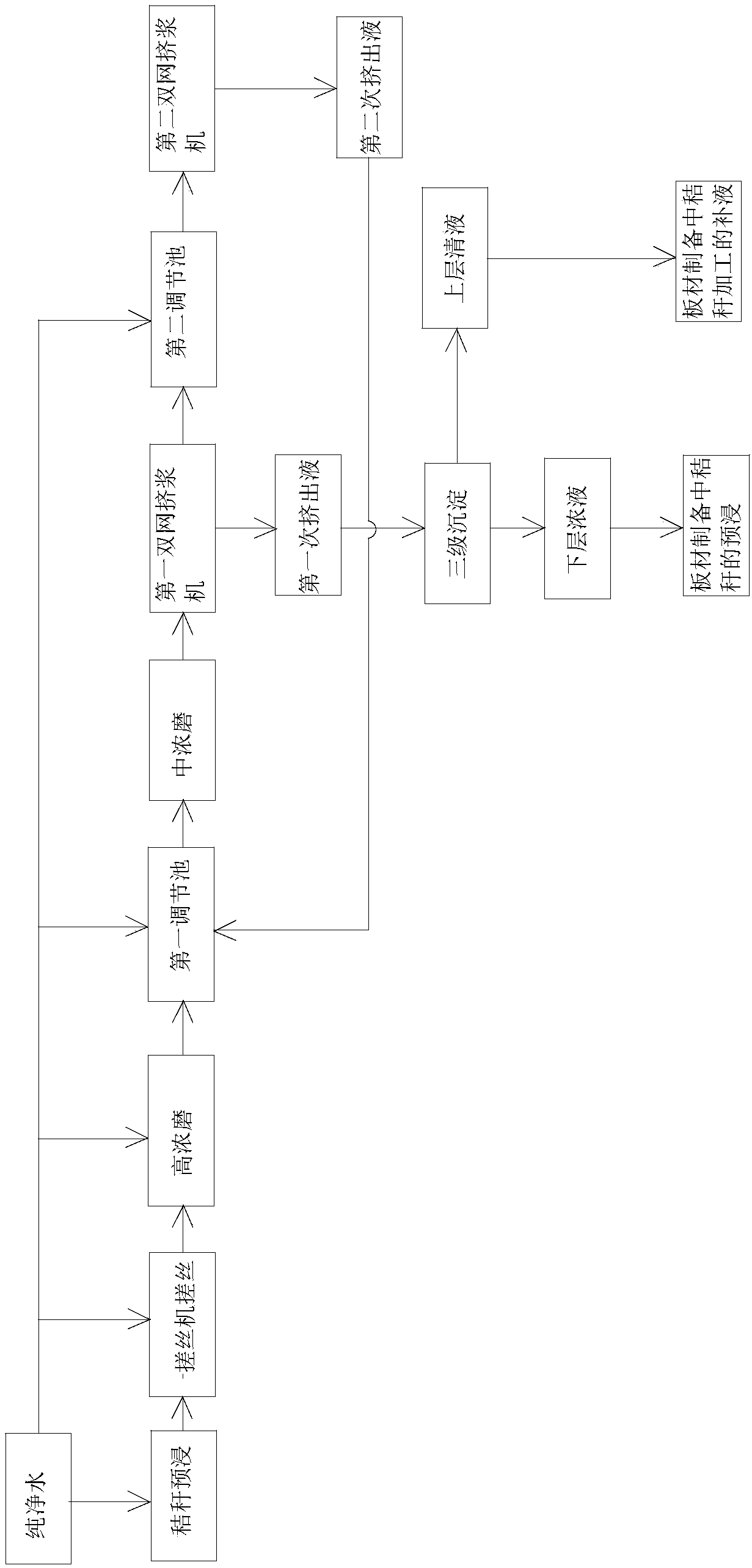

Method used

Image

Examples

Embodiment 1

[0021] Dissolve 8 parts of sodium bicarbonate in 300 parts of water to form a solution, then add 0.5 part of alkaline xylanase, 0.3 part of fatty alcohol surface penetrant, 0.3 part of activated carbon catalyst, 0.3 part of oxidized polyethylene wax, 0.3 parts of epoxidized soybean oil, stirred evenly to form a weak alkaline solution.

[0022] To process 1 ton of straw, weigh the straw, cut it off, add 700kg of weak alkaline solution through the spray pump to soak the straw, then put the soaked straw into the thread rolling machine for rubbing, and at the same time put it into the thread rolling machine Pass into 1t of pure water. After the thread rubbing is completed, all the slurry is transferred to the high-consistency mill for thermal grinding, and pure water is poured into the high-consistency mill to make the mass fraction of the slurry in the high-consistency mill reach 30%, and then transferred to the first adjustment pool For washing and dilution, the ratio of the fl...

Embodiment 2

[0024] Dissolve 9 parts of sodium bicarbonate in 320 parts of water to form a solution, then add 0.5 part of alkaline xylanase, 0.4 part of fatty alcohol surface penetrant, 0.2 part of activated carbon catalyst, 0.3 part of oxidized polyethylene wax, 0.3 parts of epoxidized soybean oil, stirred evenly to form a weak alkaline solution.

[0025] To process 1 ton of straw, weigh the straw, cut it off, add 800kg of weak alkaline solution through the spray pump to soak the straw, and then put the soaked straw into the thread rolling machine for rubbing, and at the same time put it into the thread rolling machine Pass into 1t of pure water. After the thread rubbing is completed, all the slurry is transferred to the high-consistency mill for thermal grinding, and pure water is poured into the high-consistency mill to make the mass fraction of the slurry in the high-consistency mill reach 30%, and then transferred to the first adjustment pool For washing and dilution, the ratio of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com