Integrated water purifier

A technology of water purifier and water outlet pipe, applied in the field of water purification equipment, can solve the problems of poor water quality, shortened cleaning cycle of cooling towers and other equipment, and low filtration efficiency of water purification system, so as to ensure the effect of high-efficiency filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

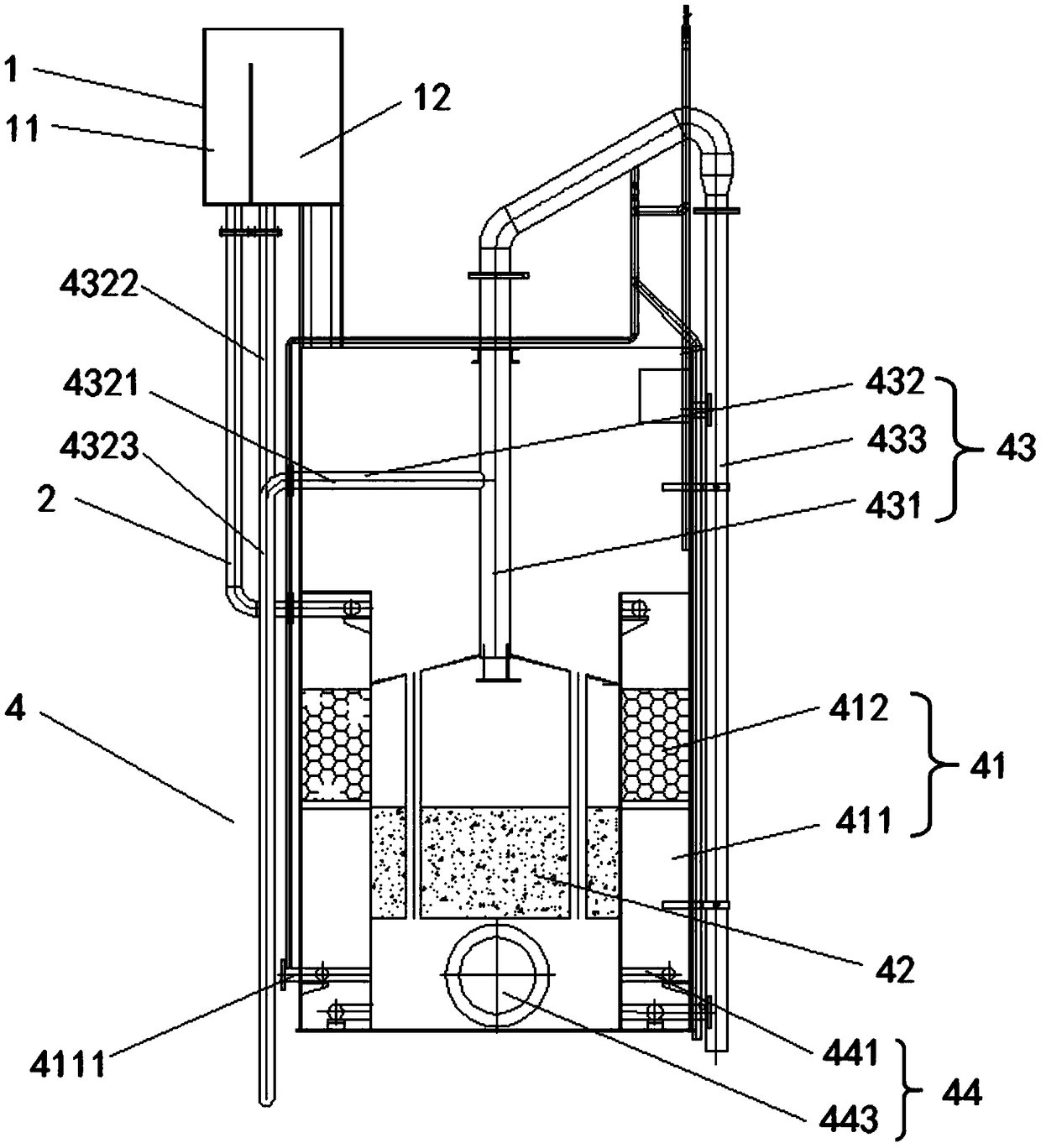

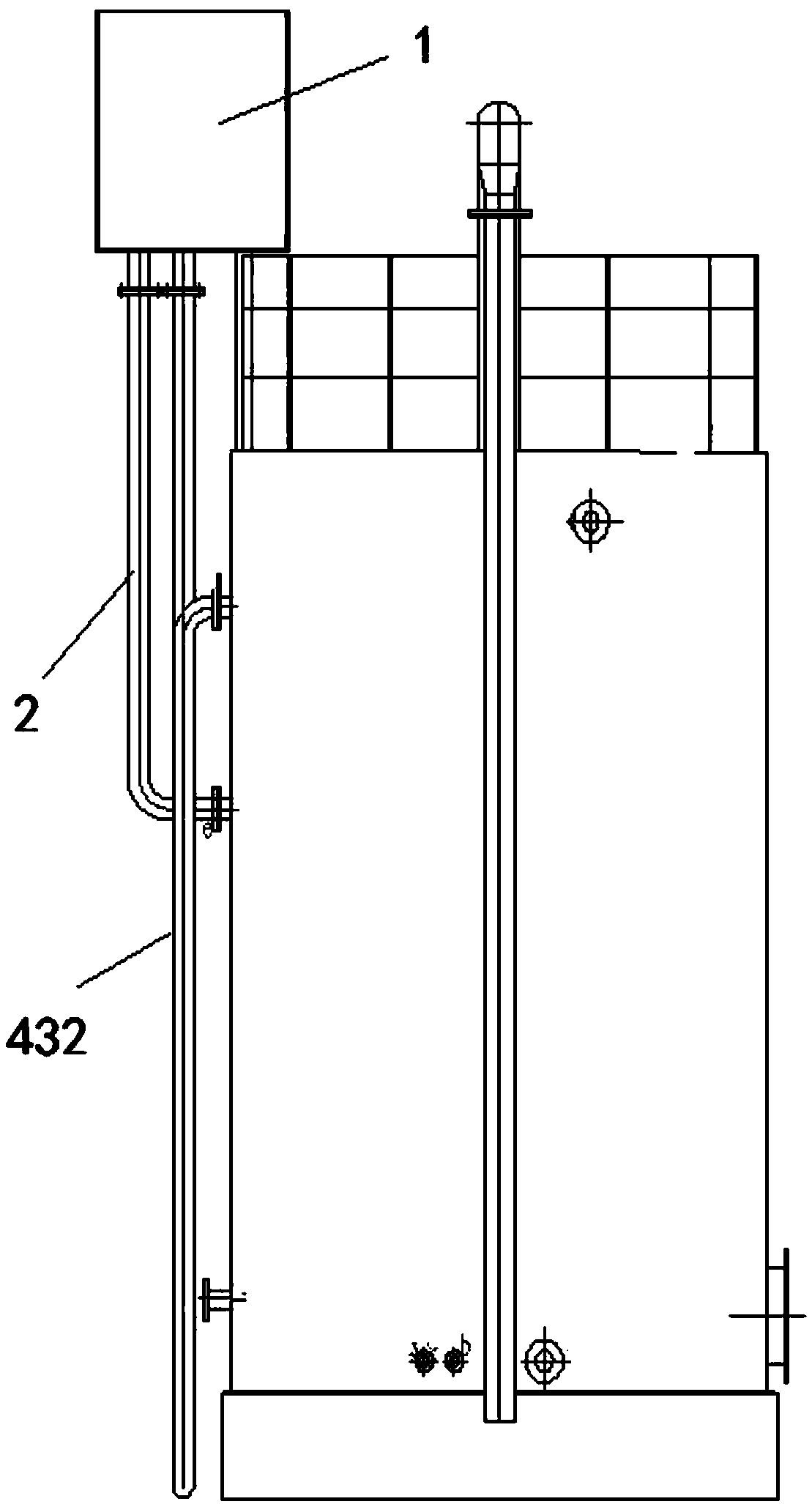

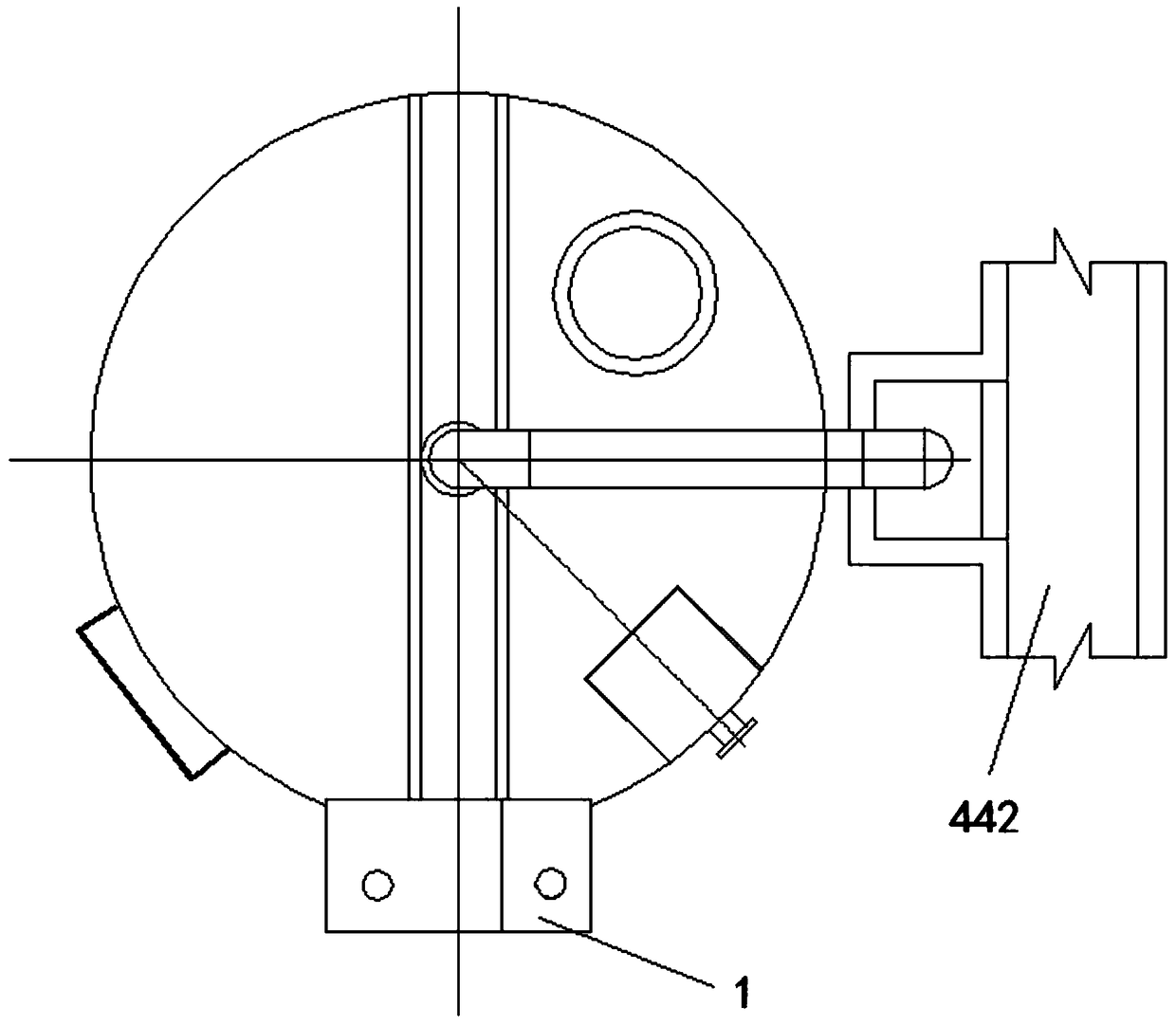

[0014] Such as figure 1 As shown, the embodiment of the present invention provides an integrated water purifier, including a high-level water tank 1, a sedimentation outlet pipe 2, a purification device 4, and a water purification outlet pipe 3;

[0015] The purification device 4 includes a purification cylinder 41, a filter chamber 42, a sewage discharge mechanism 44, and a backwash mechanism 43; the purification cylinder 41 includes a flocculation chamber 411 and a sedimentation chamber 412 located above the flocculation chamber, and below the flocculation chamber 411 A sewage water inlet 4111 is provided; the filter chamber 42 is located in the middle of the purification cylinder and is isolated from the purification cylinder; the backwash mechanism 43 includes a siphon ascending pipe 431, a siphon auxiliary pipe 432 and a siphon descending pipe 433, the The lower end of the siphon ascending pipe 431 communicates with the filter chamber 42, and the bent portion provided at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com