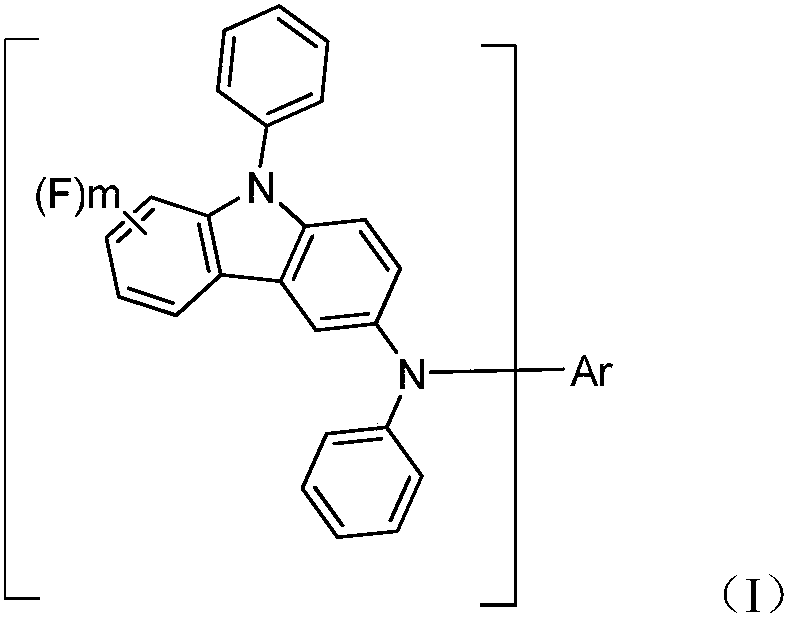

Organic light emitting diode material, synthetic method thereof and application of organic light emitting diode material in devices

A technology of electroluminescent materials and electroluminescent devices, which is applied in the fields of electric solid devices, electrical components, organic chemistry, etc., can solve problems such as low glass transition temperature, easy crystallization of materials, and destruction of film uniformity, and achieve high hole migration The effect of high efficiency and good film stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

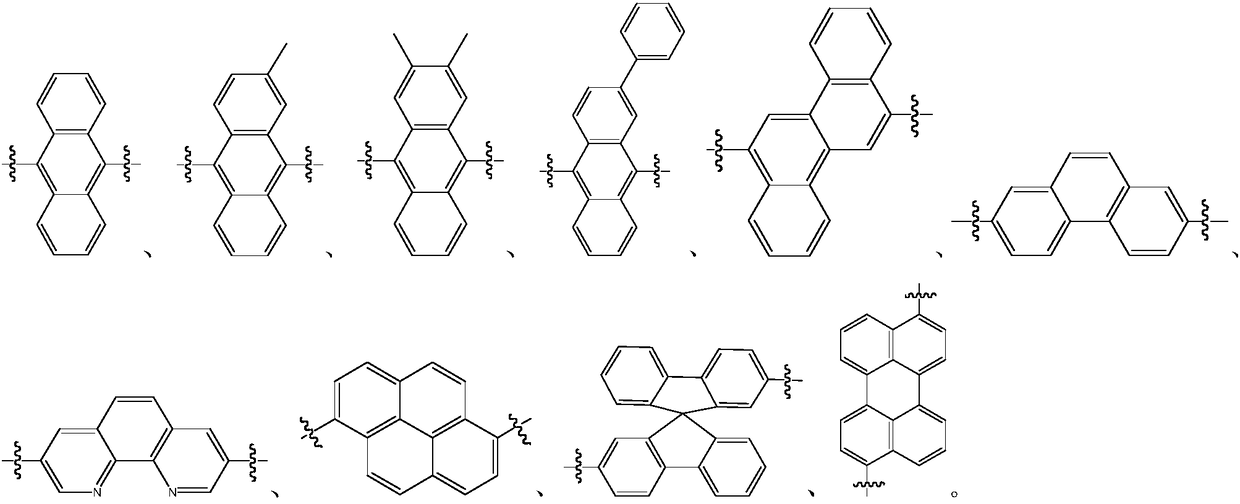

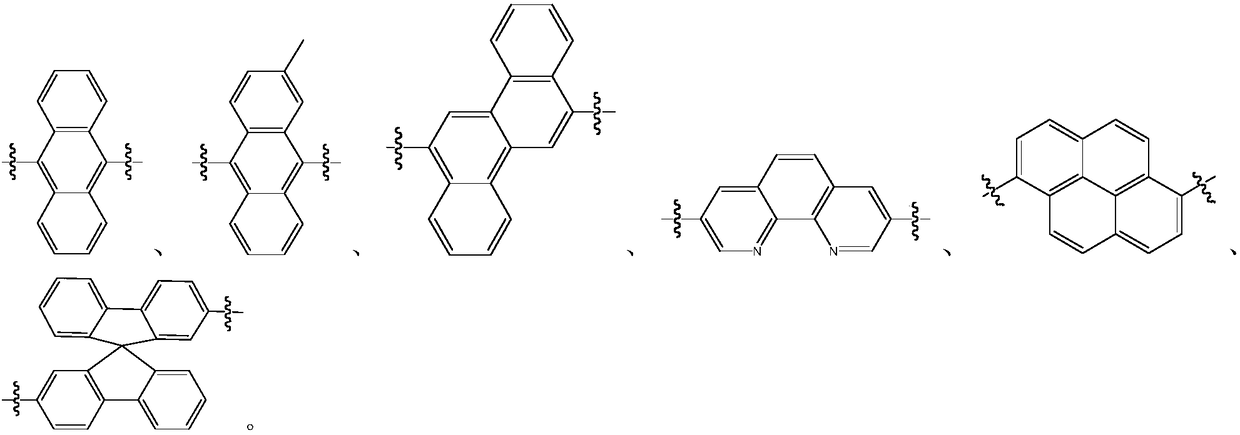

Method used

Image

Examples

Embodiment 1

[0056] Synthesis of (Compound 1)

[0057] The synthetic route is as follows:

[0058]

[0059] 1) Synthesis of compound 1-2

[0060] 1000ml three-neck flask, equipped with magnetic stirring, after argon replacement, add 46.1g (0.48mol) of sodium tert-butoxide, 27.94g (purity 99%, 0.3mol) of 2-aniline, 68.04g of 6-bromo-1-fluoro -9-Phenyl-9H-carbazole (purity 99%, 0.2 mol) and xylene 400ml. After argon replacement again, 3 ml of tri-tert-butylphosphine and 0.46 g of tris(diphenylbenzylacetone)dipalladium were added in sequence. After the addition, start stirring and heat up to 120°C, and control the temperature at 120-130°C for 5 hours. After cooling down to 30°C, the filtrate was obtained by suction filtration through a silica gel column, and the filtrate was rotary evaporated, dissolved in dichloromethane, washed twice with 4mol / L hydrochloric acid solution, separated, dried with anhydrous sodium sulfate, suction filtered, and rotary evaporated The filtrate obtained ...

Embodiment 2

[0065] Synthesis of (Compound 2)

[0066] The synthetic route is as follows:

[0067]

[0068] 1) Synthesis of compound 2-1

[0069] 1000ml three-neck flask, equipped with magnetic stirring, after argon replacement, add 46.1g (0.48mol) of sodium tert-butoxide, 27.94g (purity 99%, 0.3mol) of 2-aniline, 68.04g of 6-bromo-1-fluoro -9-Phenyl-9H-carbazole (purity 99%, 0.2 mol) and toluene 400ml. After argon replacement again, 3 ml of tri-tert-butylphosphine and 0.46 g of tris(diphenylbenzylacetone)dipalladium were added in sequence. After the addition, start stirring and heat up to 100°C, and control the temperature at 100-110°C for 5 hours. After cooling down to 30°C, the filtrate was obtained by suction filtration through a silica gel column, and the filtrate was rotary evaporated, dissolved in dichloromethane, washed twice with 4mol / L hydrochloric acid solution, separated, dried with anhydrous sodium sulfate, suction filtered, and rotary evaporated The filtrate obtained...

Embodiment 3

[0074] Synthesis of (Compound 3)

[0075] The synthetic route is as follows:

[0076]

[0077] 1) Synthesis of compound 3-1

[0078] 1000ml three-neck flask, equipped with magnetic stirring, after argon replacement, add 46.1g (0.48mol) of sodium tert-butoxide, 27.94g (purity 99%, 0.3mol) of 2-aniline, 68.04g of 6-bromo-1-fluoro -9-Phenyl-9H-carbazole (purity 99%, 0.2 mol) and xylene 400ml. After argon replacement again, 3 ml of tri-tert-butylphosphine and 0.46 g of tris(diphenylbenzylacetone)dipalladium were added in sequence. After the addition, start stirring and heat up to 110°C, and control the temperature at 110-120°C for 5 hours. After cooling down to 30°C, the filtrate was obtained by suction filtration through a silica gel column, and the filtrate was rotary evaporated, dissolved in dichloromethane, washed twice with 4mol / L hydrochloric acid solution, separated, dried with anhydrous sodium sulfate, suction filtered, and rotary evaporated The filtrate obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com