Medium-high-temperature oil well cement retarding agent as well as preparation method and application thereof

A technology of oil well cement and retarder, which is applied in the fields of oil well cement retarder and medium-high temperature oil well cement retarder. It can solve the problems of high initial consistency, over-retarding of cement slurry at the top, and sensitivity to dosage, etc., and reach the applicable temperature. The effects of wide range, overcoming sensitivity to dosage, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

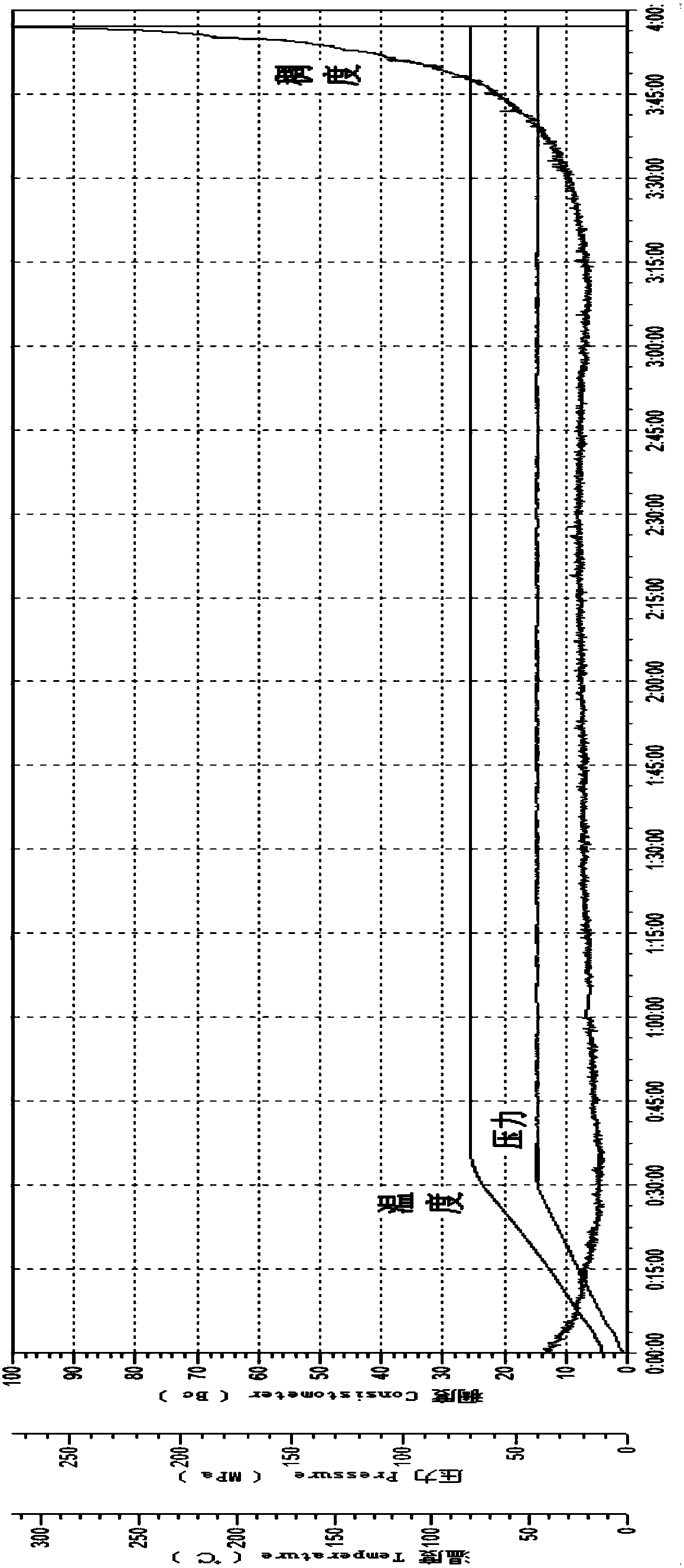

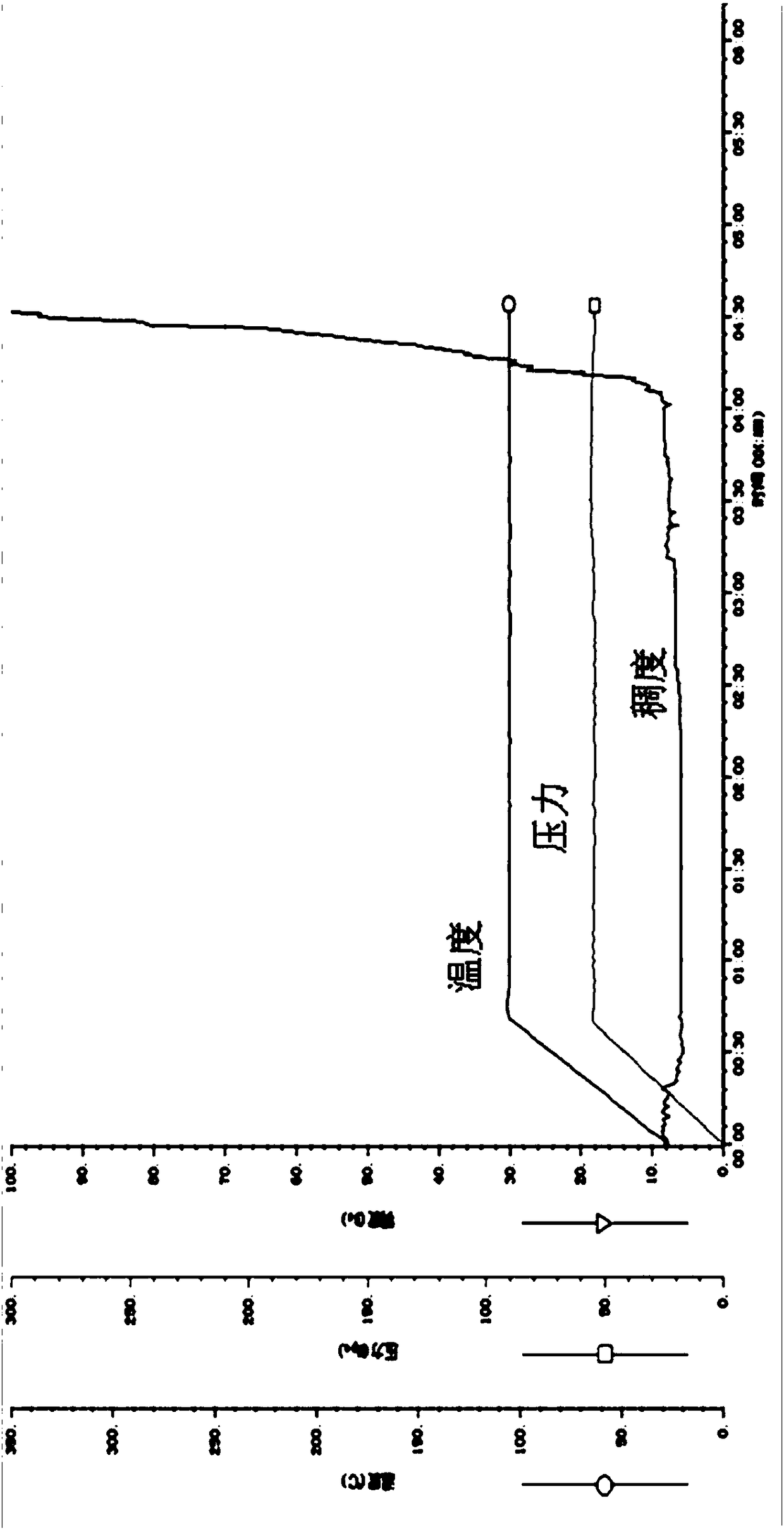

Image

Examples

preparation example Construction

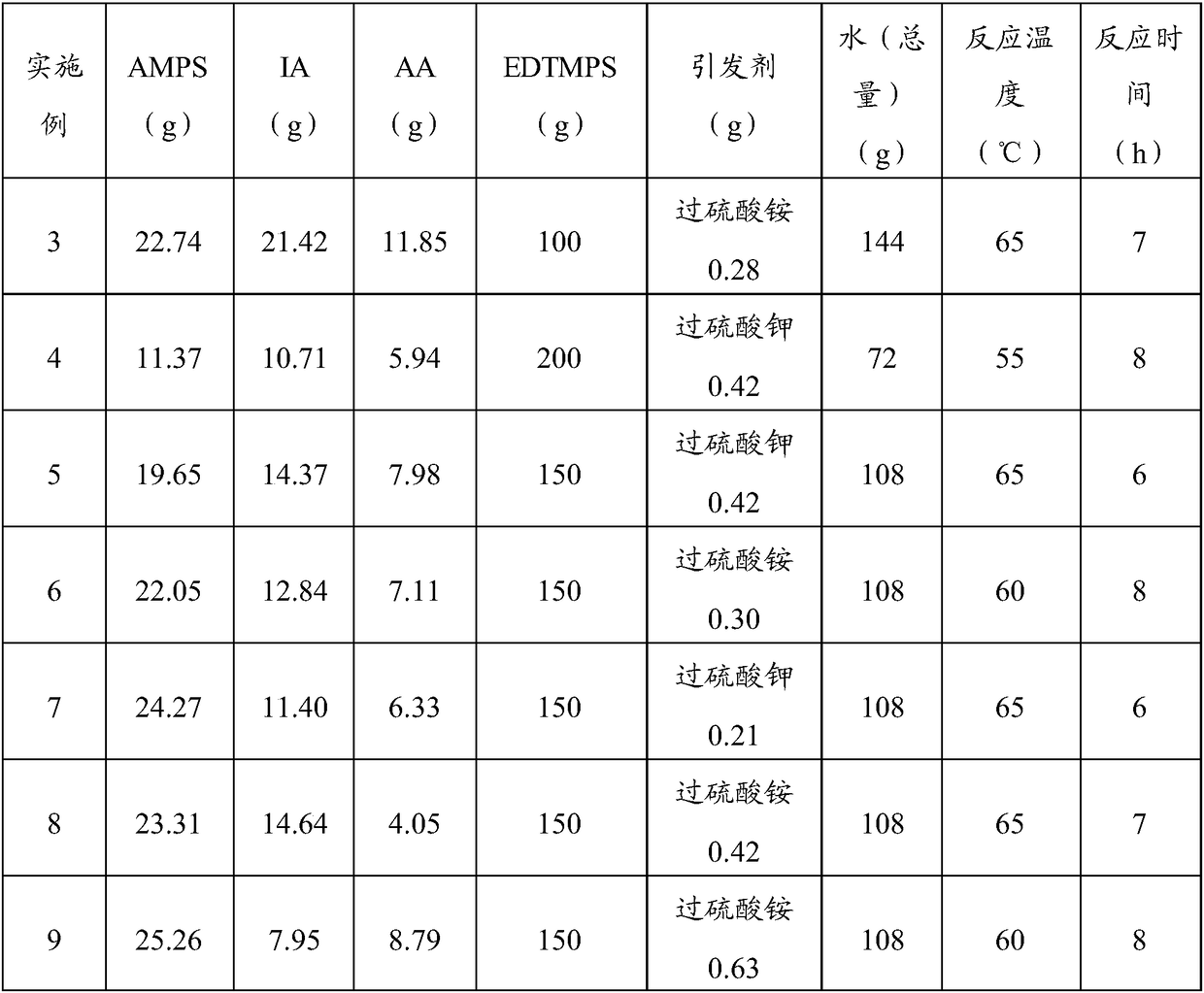

[0022] The invention provides a kind of preparation method of medium and high temperature oil well cement retarder, comprising the following steps:

[0023] In the presence of organic phosphonate and initiator, itaconic acid, acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid are polymerized in water to obtain a medium-high temperature oil well cement retarder.

[0024] One of the purposes of the present invention is to provide a method for preparing a medium-high temperature oil well cement retarder. The obtained retarder has a better retarding effect under medium-high temperature conditions, and is not sensitive to the dosage, and has a wide applicable temperature range during application. , High strength of cement stone top, etc.

[0025] The invention mainly adopts water-soluble monomers such as itaconic acid to carry out polymerization in an aqueous solution of organic phosphonate. The monomers described in the present invention include itaconic acid, acrylic aci...

Embodiment 1

[0039] Add 16.08g of IA and 40g of water into a 500mL four-necked flask equipped with a thermometer, condenser and stirrer, raise the temperature to 45°C and stir for 15 minutes to dissolve completely, then weigh 8.88g of AA and 17.04g of AMPS and dissolve them in 60g of water , it is transferred to the four-necked flask, then weigh 150g EDTMPS solution (commercially available product, effective concentration is 28%), stir evenly, be warming up to 60 ℃, add the aqueous solution that 8g contains 0.42g initiator ammonium persulfate In this flask, constant temperature reaction 8h, obtains 300g retarder. The molecular weight was 5000, and the molecular weight distribution was 4.99.

Embodiment 2

[0041] Add 19.26g of IA and 50g of water into a 500mL four-necked flask equipped with a thermometer, a condenser, and a stirrer, raise the temperature to 45°C and stir for 15 minutes to dissolve completely, then weigh 10.68g of AA and 20.46g of AMPS and dissolve them in 70g of water , it is transferred to the four-necked flask, then take by weighing 120g EDTMPS solution (concentration is 28%), stir evenly, be warming up to 60 ℃, 9.6g will contain the aqueous solution of 0.76g initiator potassium persulfate to add in the flask, constant temperature After reacting for 6 hours, 300g retarder was obtained. The molecular weight is 8000, and the molecular weight distribution is 3.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com