A high-efficiency compact capillary heat exchanger

A capillary tube and heat exchanger technology, which is applied in the field of high-efficiency and compact capillary tube heat exchangers, can solve the problems of large pressure drop in the tube side of the overall heat exchanger, achieve compact structure, reduce length, and improve heat exchange efficiency and heat transfer coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

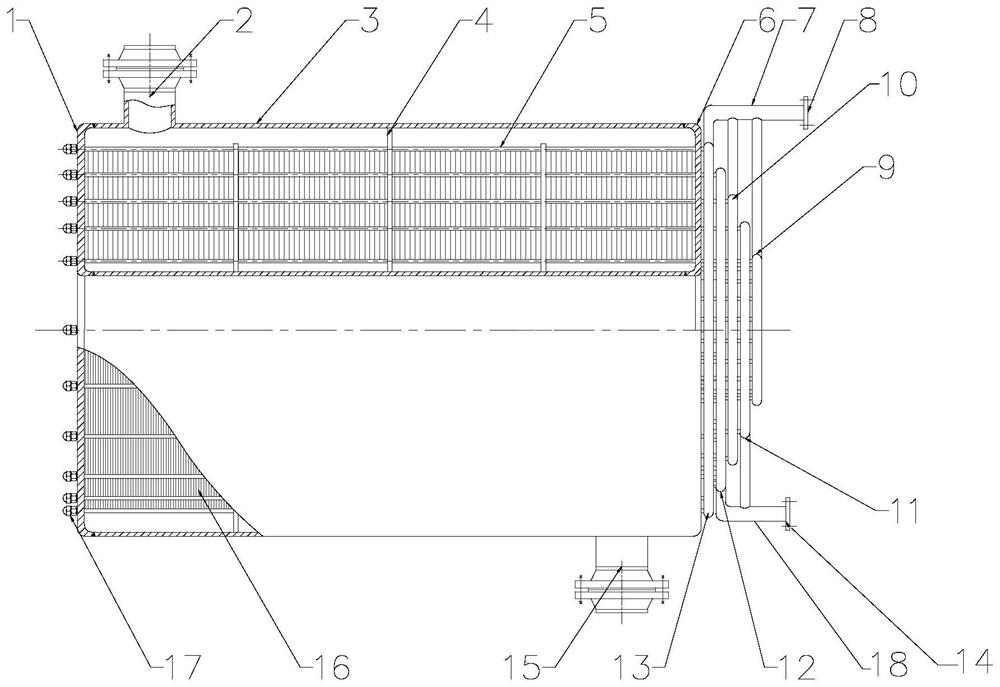

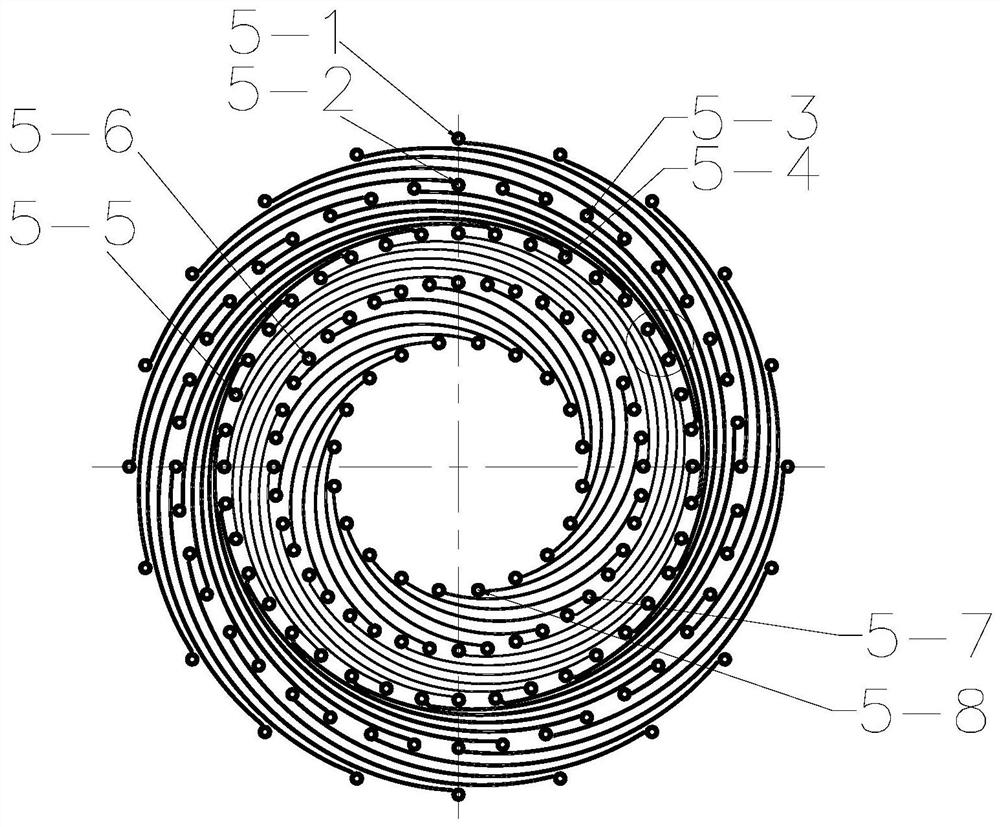

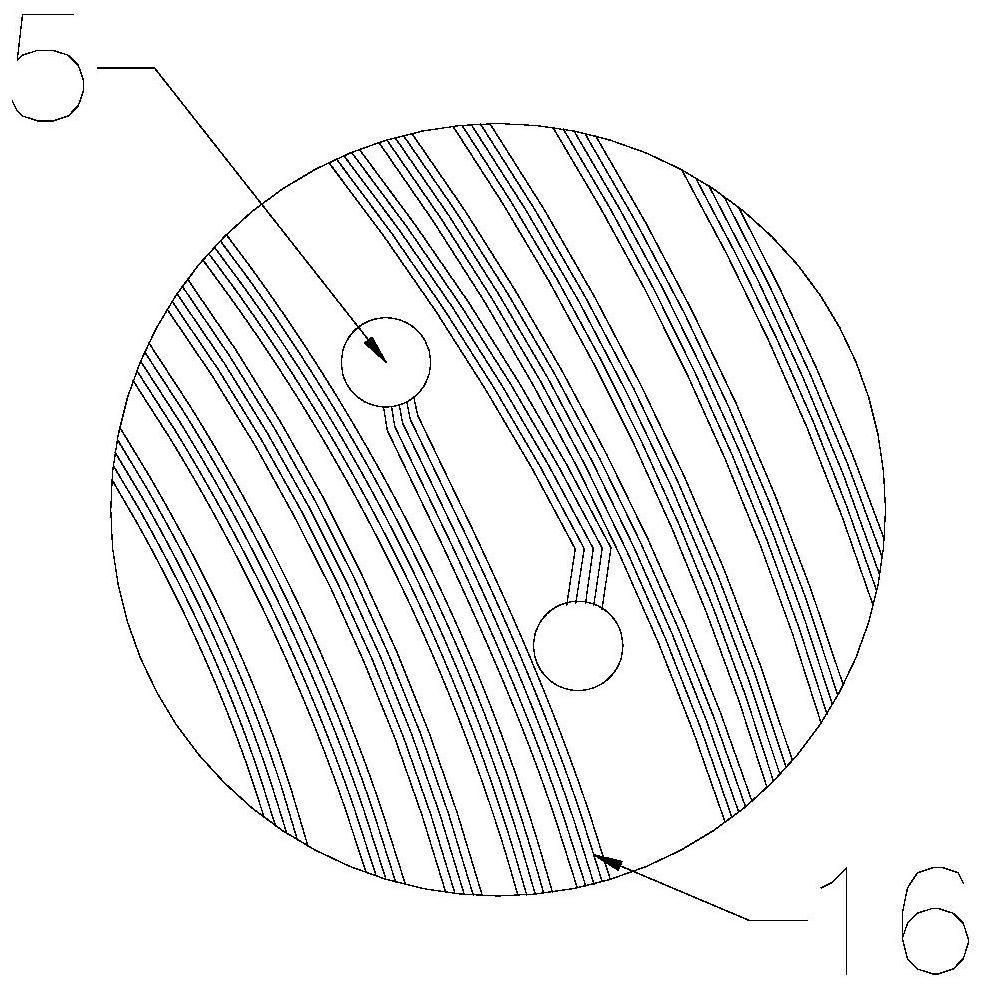

[0029] The invention proposes a high-efficiency and compact capillary heat exchanger, which greatly improves the heat exchange efficiency of the equipment. Under the same working conditions, the heat exchange coefficient is large, and the same heat can be exchanged with a smaller heat exchange area, so its structure is compact and large. The volume and weight of the device are greatly reduced. At the same time, the new tube layout method effectively reduces the length of the capillary, which can solve the problem of excessive pressure drop caused by the capillary. The tube sheet which plays the role of support and fixation also acts as a baffle to improve the heat transfer coefficient of the shell side.

[0030] In conjunction with the accompanying drawings, a high-efficiency and compact capillary heat exchanger includes a cylinder 3, a primary capillary 16, a secondary header 5 and a tertiary annular tube. The center of the cylinder is a cylindrical hollow structure, and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com