Micro-bubble preparation method, air supply system and preparation equipment

A gas supply system and microbubble technology, which is used in pharmaceutical formulations, microcapsules, nanocapsules, etc., can solve the problem of uneven concentration of microbubbles, difficult to ensure the consistency of microbubble concentration, and affect the consistency of microbubble product parameters, etc. problems, to achieve the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0097] As known in the art, conventional microbubble preparation methods can prepare microbubbles for targeted delivery. The main steps include: first dissolving drugs, genes or trace element ions and film-forming materials in water or organic solvents, making the drugs , genes or trace element ions are combined with the film-forming material through physical or chemical action to form a composite film, and then the previously obtained composite film is prepared into microbubbles by a preset method of generating microbubbles.

[0098] Since the toxicity and medicinal dosage of drugs or trace elements need to be accurately grasped, and the content of drugs or trace elements is closely related to the concentration of targeted delivery microbubbles, in order to ensure the consistency and accuracy of the content of drugs or trace elements The consistency and accuracy of microbubble concentration values need to be controlled during the preparation process.

[0099] Film forming...

Embodiment approach

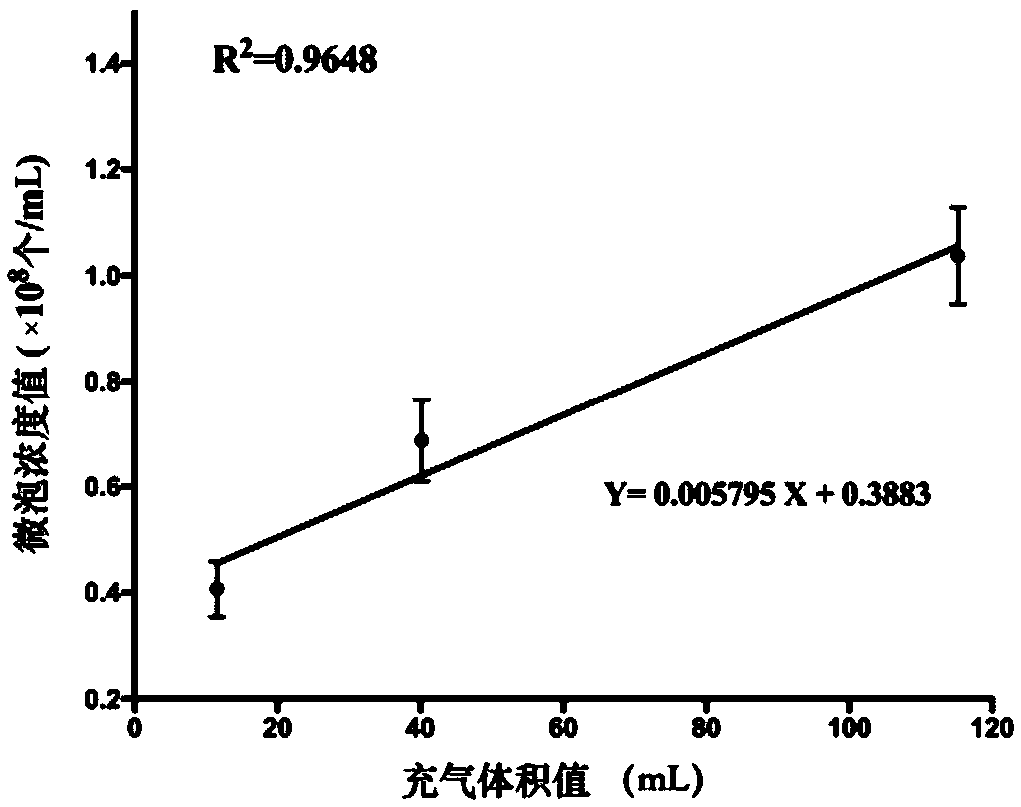

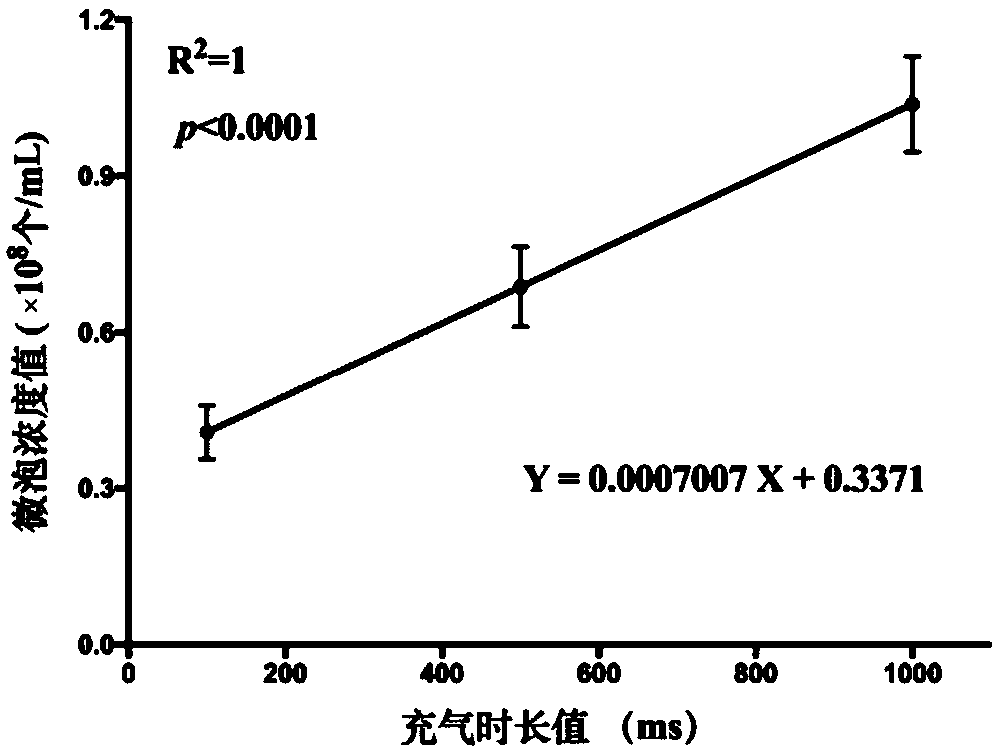

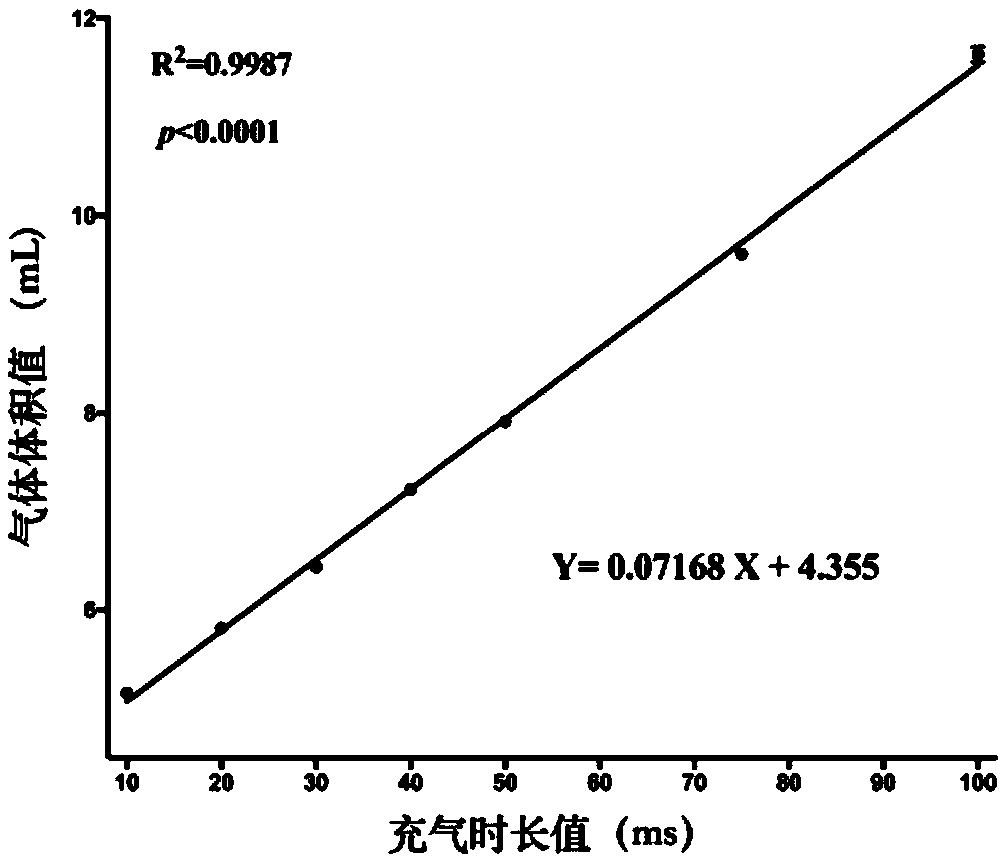

[0138]In other embodiments, other methods can also be used to determine the inflation pressure value, for example: in the case where the inflation volume value corresponding to the microbubble concentration value can be directly determined, the mapping relationship between the inflation volume value and the inflation pressure value can also be used Determine the inflation pressure value. The specific steps include: setting the inflation volume value; determining the inflation pressure value corresponding to the inflation volume value according to the preset mapping relationship between the inflation volume value and the inflation pressure value; Gas required for microbubbles. In this way, an effective control method for obtaining a value close to the expected microbubble concentration is provided, thereby bringing the beneficial effect of better accuracy of the microbubble concentration. As an implementation, the specific steps of determining the inflation pressure value incl...

Embodiment 1

[0183] Example 1: Air supply system of microbubble preparation device

[0184] Such as Figure 6 As shown, the gas supply system of the microbubble preparation device in this embodiment includes: a gas source 1 to provide the gas needed to form microbubbles; a gas path, one end of the gas path is connected to the gas source 1, and the other end of the gas path is connected to The gas inlet of reaction vessel 8; Inflatable volume control part, the inflatable volume control part can control the volume that is filled with gas to reaction vessel 8, and the gas source 1 in the present embodiment is a high-pressure gas cylinder, and it is stored with the gas required for forming microbubbles. gas. For example: perfluoropropane, sulfur hexafluoride or perfluorobutane, the high-pressure gas cylinder has a gas outlet, and the gas outlet is connected to one end of the gas circuit. The gas path in this embodiment mainly includes pipelines. Preferably, the gas path also includes struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com