Preparation method of recycled aggregate for inhibiting alkali-aggregate reaction

A technology for recycled aggregates and aggregates, applied in the field of recycled aggregates, can solve the problems of primary aggregate damage, high requirements for solution concentration and soaking time, and large energy consumption, and achieves convenient installation and maintenance, shortened processing time, and reduced processing time. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

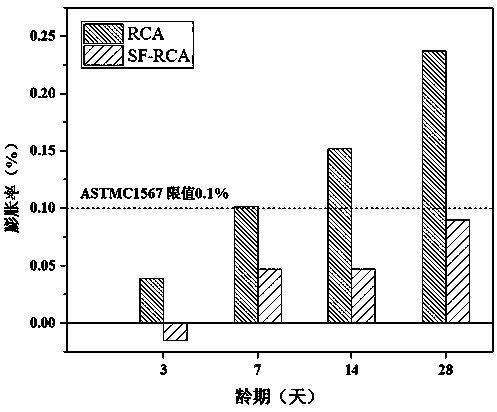

[0021] The recycled aggregate in this example comes from recycled concrete with a compressive strength of 30 MPa after pouring and curing for 28 days. The alkali-active aggregate used is Xiangjiang pebbles that have been verified as alkali-active aggregate by many experiments, and will be crushed and screened to the specified gradation according to the ASTM C1567 standard.

[0022] In step (3), according to the ASTM C1567 alkali-aggregate reaction expansion test method, the prepared recycled aggregate was used to form the test piece, and the particle size distribution of the recycled aggregate without treatment and vacuum inhaled silica fume slurry was 4.75- 2.36 mm, 2.36-1.18mm, 1.18-0.6mm, 0.6-0.3 mm and 0.3-0.15mm, the mass proportions are 10%, 25%, 25%, 25% and 15% respectively. The following examples are the same.

[0023] The auxiliary cementitious material that can effectively inhibit the alkali-aggregate reaction of concrete, which is made of recycled concrete aggrega...

Embodiment 2

[0030] The recycled aggregate in this example comes from recycled concrete with a compressive strength of 30 MPa after pouring and curing for 28 days. The alkali-active aggregate used is Xiangjiang pebbles that have been verified as alkali-active aggregate by many experiments, and will be crushed and screened to the specified gradation according to the ASTM C1567 standard.

[0031] The auxiliary cementitious material that can effectively inhibit the alkali-aggregate reaction of concrete, which is made of recycled concrete aggregate after vacuum suction treatment of silica fume slurry, is made according to the following steps:

[0032] (1) Collection of recycled aggregate: crush and sieve recycled concrete with a compressive strength of 30MPa after pouring and curing for 28 days to obtain recycled aggregate with a particle size of ≤4.75mm;

[0033] (2) Preparation of silica fume slurry: Dissolve silica fume in water according to the water-solid mass ratio of 10:1 to prepare silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com