Novel method for improving expression amount of alpha-galactosidase displayed on surfaces of saccharomyces cerevisiae cells prepared by fermentation tank

A technology of Saccharomyces cerevisiae cells and galactosidase, which is applied in the field of enzyme engineering to achieve the effects of increasing expression and promoting bacterial growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

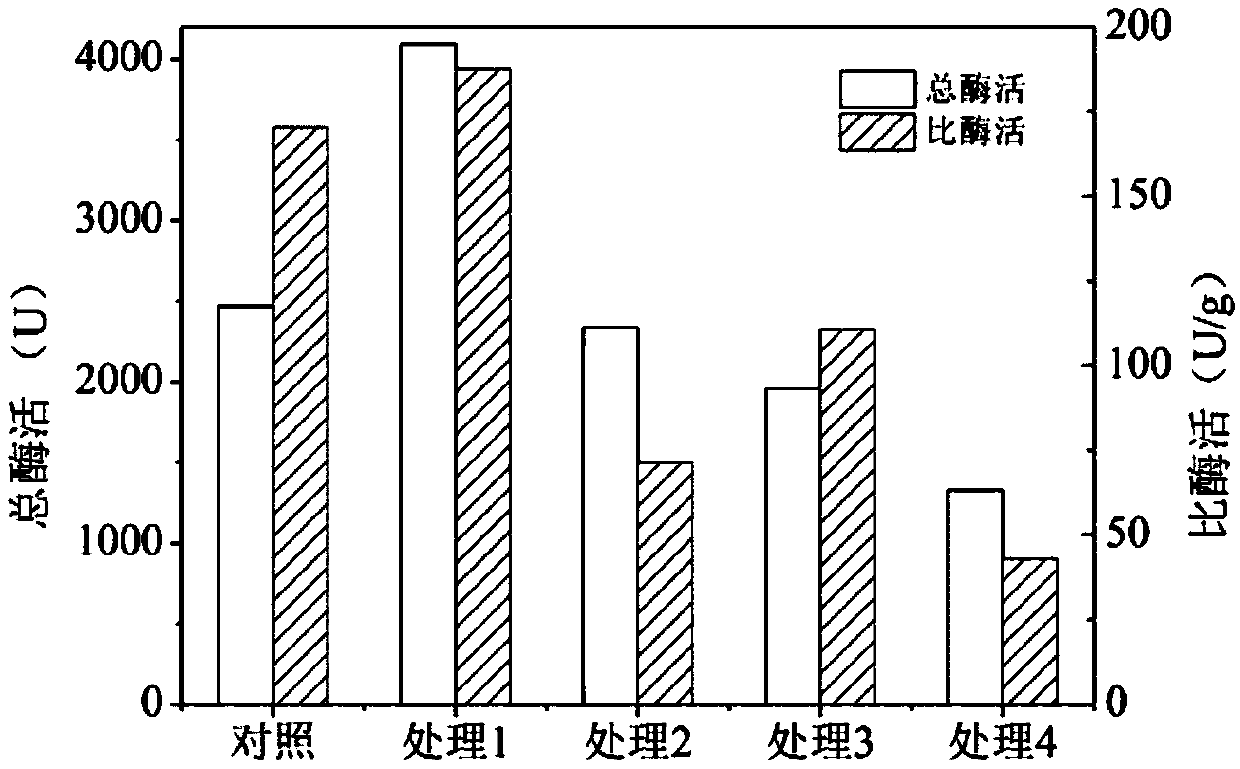

[0033] In a 10L fermentor, the seed solution of α-galactosidase displayed on the cell surface of S. %acid hydrolyzed casein, 2% galactose, 0.5% ammonium sulfate), the stirring speed is 100rpm, the air is fed at a speed of 0.5L / min, at 20°C, the induced expression is 30h, and the induced expression of α-galactosidase is centrifuged Collect the bacteria, resuspend the bacteria with a McIlvaine buffer solution of pH=5 at a concentration of 0.1 g / mL, and measure the unit enzyme activity. The results are as follows: figure 1 (corresponding to figure 1 The processing in 1) is shown. The unit enzyme activity obtained by adding 0.5% ammonium sulfate was 187.5U / g, and the recovered total enzyme activity was 4095.8U, which were 1.1 times and 1.7 times that of the control group, respectively.

Embodiment 2

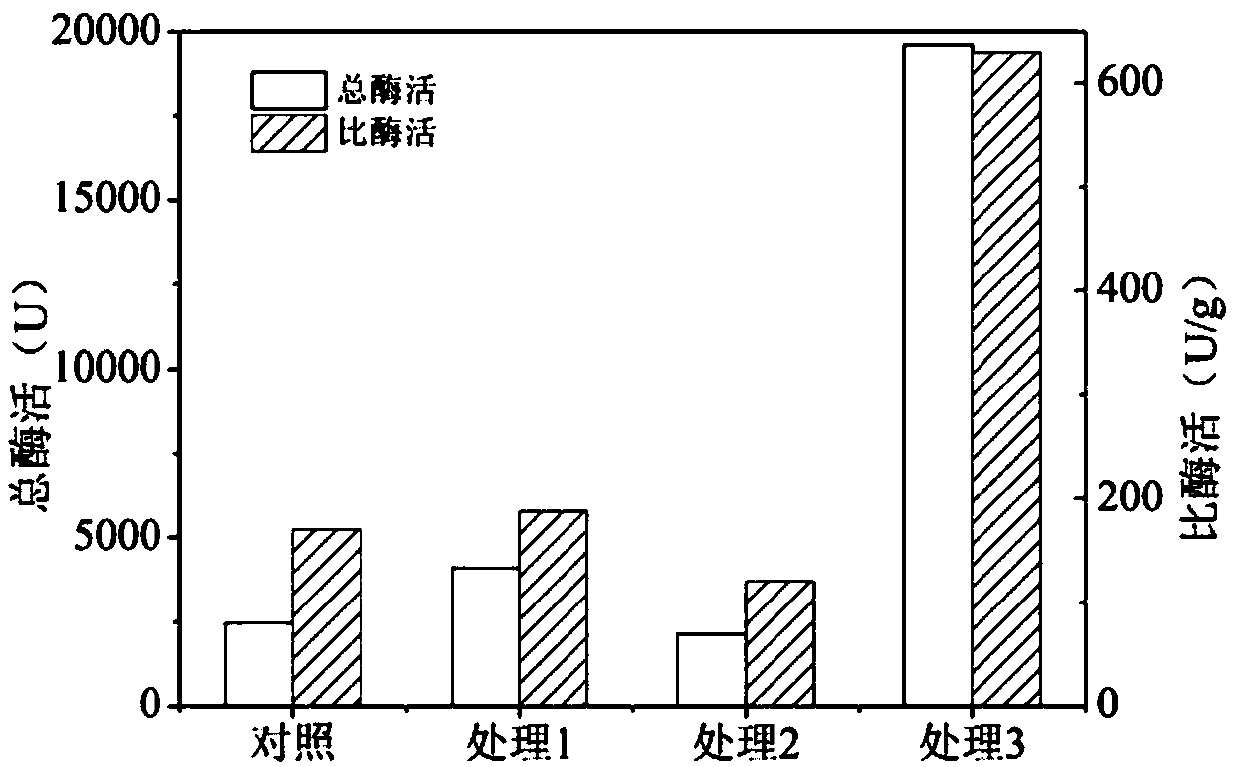

[0039] In a 10L fermentor, the seed solution of α-galactosidase displayed on the surface of Saccharomyces cerevisiae cells was inoculated into the YNB-CAA medium (0.67% YNB, 0.5 % acid hydrolyzed casein, 2% galactose, 0.5% ammonium sulfate), the stirring speed is 100rpm, the air is fed in at a speed of 0.5L / min, and the expression is induced for 30h at 20°C. During the induction process, 20% of Galactose, ensure that the concentration of galactose in the medium is 1-3%, collect the bacteria by centrifugation, and resuspend the bacteria with McIlvaine buffer with pH=5 at a concentration of 0.1g / mL. The results are as follows: figure 2 (corresponding to figure 2 As shown in the treatment 3) in , the measured unit enzyme activity was 630.2U / g, and the total enzyme activity recovered was 19632.0U, which were 3.7 times and 7.9 times that of the control group, respectively.

[0040] Comparative Example 1: In Example 2, galactose was not added during the induction process of induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com