Fermentation method for promoting high yield of oil of rhizopus arrhizus and used culture medium

A fermentation medium and a technology for Rhizopus oligoides, applied in the field of microbial fermentation, can solve the problems of affecting the quality and yield of microbial oil, reducing the total number of strains, and difficulty in oil collection, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of fermentation method that promotes the high-yielding oil and fat of Rhizopus arrhizus comprises the following steps:

[0034] (1) Activation of Rhizopus aureus strains: pick a small amount of mycelium or spores of Rhizopus aureus and insert them into the slant medium (according to 1L, the formula is: 200g of potatoes, 20g of glucose, 3.0g of potassium dihydrogen phosphate , magnesium sulfate 1.5g, agar 20g, pH natural) in a test tube, placed in an incubator for 5-7d, until a large number of spores grow, the culture temperature is 28 ℃.

[0035] (2) Shake flask culture: wash the spores on the slope with sterile water and insert them into the seed medium (according to 1L, the formula is: 55g of glucose, 3.0g of ammonium nitrate, 2.0g of yeast extract, 0.75g of sodium chloride, Potassium dihydrogen phosphate 2.1g, magnesium sulfate 0.8g, calcium chloride 40mg, ferric chloride 24mg, EDTA 27mg, copper sulfate 0.15mg, zinc sulfate 0.3mg, manganese sulfate 0.3mg, nico...

Embodiment 2

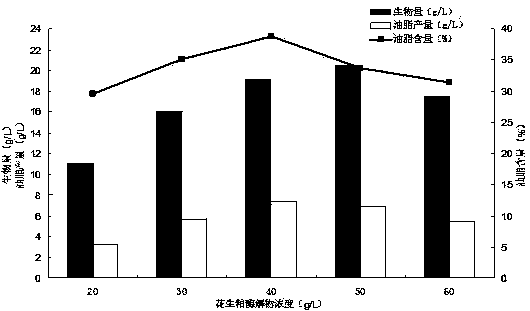

[0039] Embodiment 2: The influence of the concentration of peanut meal enzymatic hydrolyzate on the fat production of Rhizopus arrhizus fermentation

[0040] Referring to Example 1, the difference is that peanut meal hydrolyzate with a concentration of 20g / L, 30g / L, 40g / L, 50g / L, and 60g / L is added to the fermentation medium, and the other components remain unchanged. to cultivate. After the fermentation, the biomass, oil content and oil production of the bacteria were measured, and the results are shown in figure 1 .

[0041] From figure 1 It can be seen that when the concentration of peanut meal enzymatic hydrolyzate was 50g / L, the thalline biomass of Rhizopus arrhizus was 20.52g / L, the oil content was 33.66% under this concentration, and the oil yield was also higher, being 6.91g / L L; when the concentration of peanut meal hydrolyzate was 40g / L, the highest oil content of Rhizopus arrhizus was 38.81%, the highest oil yield was 7.44g / L, and the biomass was 19.16g / L. Peanu...

Embodiment 3

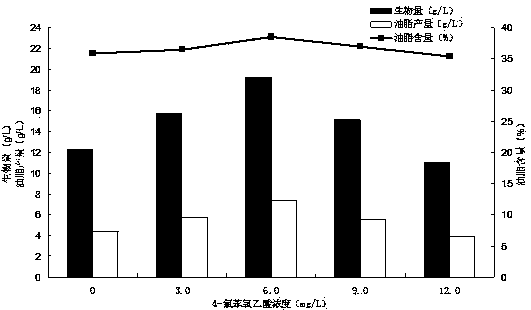

[0042] Embodiment 3: the influence of the concentration of 4-chlorophenoxyacetic acid on the fermentation of rhizopus arrhizus to produce fat

[0043] Referring to Example 1, the difference is that 4-chlorophenoxyacetic acid with a concentration of 3.0mg / L, 6.0mg / L, 9.0mg / L, and 12.0mg / L is added to the fermentation medium, so as not to add 4-chlorophenoxyacetic acid. Phenoxyacetic acid was used as a control, and other components were kept unchanged, and the fermentation culture was carried out. After the fermentation, the biomass, oil content and oil production of the bacteria were measured, and the results are shown in figure 2 .

[0044] 4-Chlorophenoxyacetic acid is a plant growth regulator. Its biological activity lasts for a long time, and its physiological effects are similar to endogenous hormones. It stimulates cell division and tissue differentiation. It is widely used in flowers, crops and fruit trees. And find that 4-chlorophenoxyacetic acid has the effect of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com