Flexible organic thermoelectric device and preparation method thereof

A thermoelectric device, an organic technology, applied in the direction of thermoelectric devices, thermoelectric device manufacturing/processing, electrical components, etc., can solve the problem of not being able to maintain the temperature difference between the heat sink end and the heat source end, hindering the large-scale application of thin-film thermoelectric batteries, and the output of thermoelectric batteries Low power and other issues, to achieve excellent industrial applicability, low manufacturing cost, and increase output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

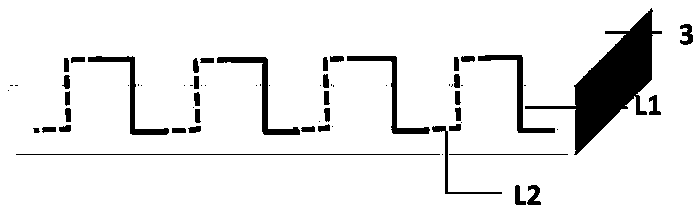

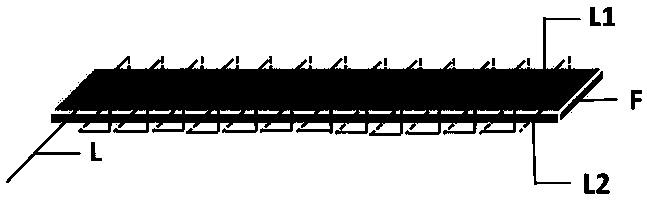

[0043] In this embodiment, poly-3-hexylthiophene is used as a P-type material, and conductive silver paste is used as an N-type material. like figure 1 As shown, in the preparation process, a cotton thread L with a length of 30 cm and a diameter of 1 mm was first prepared, and the cotton thread L was immersed in a toluene solution of 8 mg / ml poly-3-hexylthiophene. With the slow volatilization of the solvent, the polymer Gradually adsorbed on the fiber surface of the cotton thread L. Then, the cotton thread L loaded with poly-3-hexylthiophene polymer is evenly encircled along the iron sheet F with a width of 8 mm, and the two sides of the iron sheet F are brushed with bistrifluoromethanesulfonimide iron and silver paste respectively, After standing and drying for 2 hours, remove the cotton thread L from the iron sheet F. At this time, the P-type and N-type materials on the cotton thread L are evenly spaced.

[0044] Cotton thread L loaded with P-type and N-type materials and ...

Embodiment 2)

[0047] In this embodiment, polyaniline is used as the P-type material, and conductive silver paste is used as the N-type material. like figure 1 As shown, in the preparation process, a cotton thread L with a length of 20 cm and a diameter of 1 mm was firstly prepared, and the cotton thread L was immersed in a 10 mg / ml polyaniline m-cresol solution. As the solvent volatilized slowly, the polymer gradually Adsorbed on the fiber surface of cotton thread L. Then, the polyaniline-loaded cotton thread L is evenly encircled along the iron sheet F with a width of 8 mm, and the m-cresol solution of camphorsulfonic acid and the silver paste are brushed on both sides of the iron sheet F, and left to dry for 2 hours. , Remove the cotton thread L from the iron sheet F. At this time, the P-type and N-type materials on the cotton thread L are evenly spaced.

[0048] Cotton thread L loaded with P-type and N-type materials and evenly spaced is sewn on a dense sponge with a thickness of 5 mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com