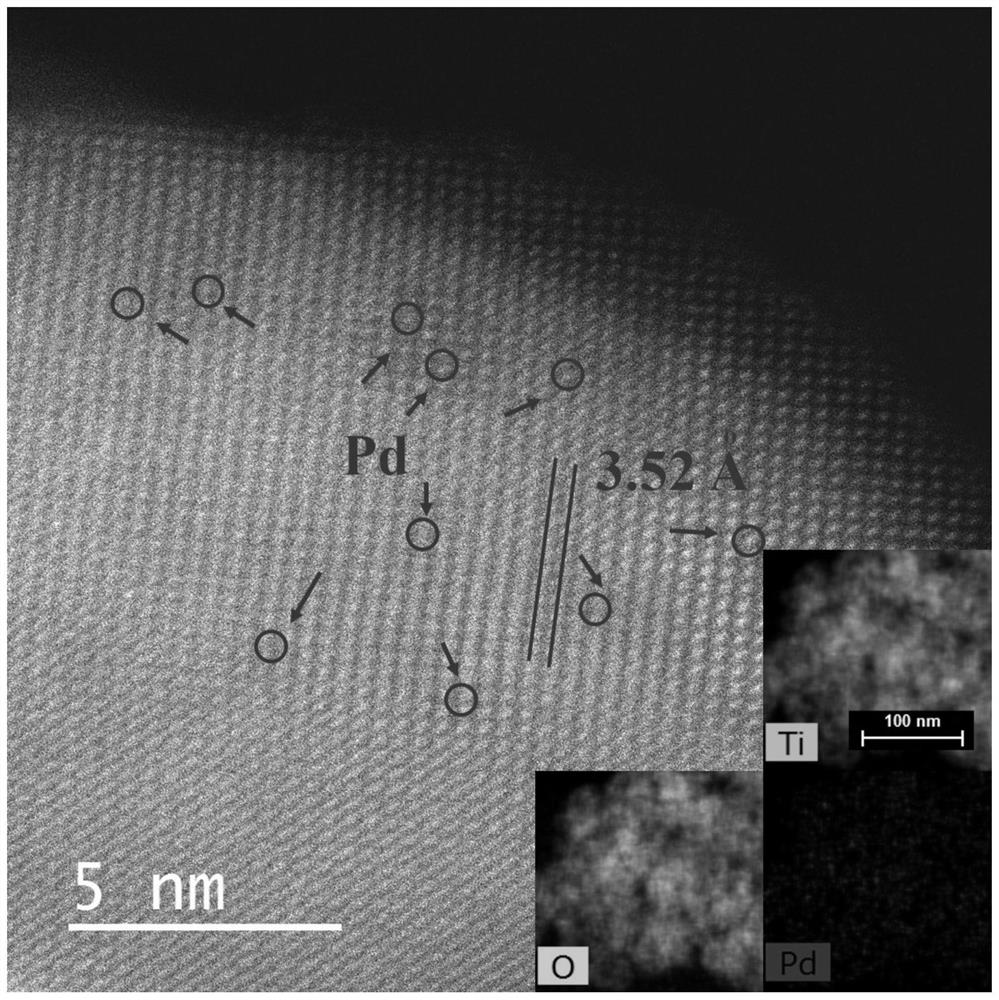

A palladium-based catalyst for thermocatalytic formaldehyde degradation

A formaldehyde degradation and catalyst technology, which is applied in the field of thermal catalytic materials and environmental protection, can solve the problems of high catalyst manufacturing cost, limitation, high-temperature calcination, etc., and achieve the effect of improving capacity, convenient operation and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

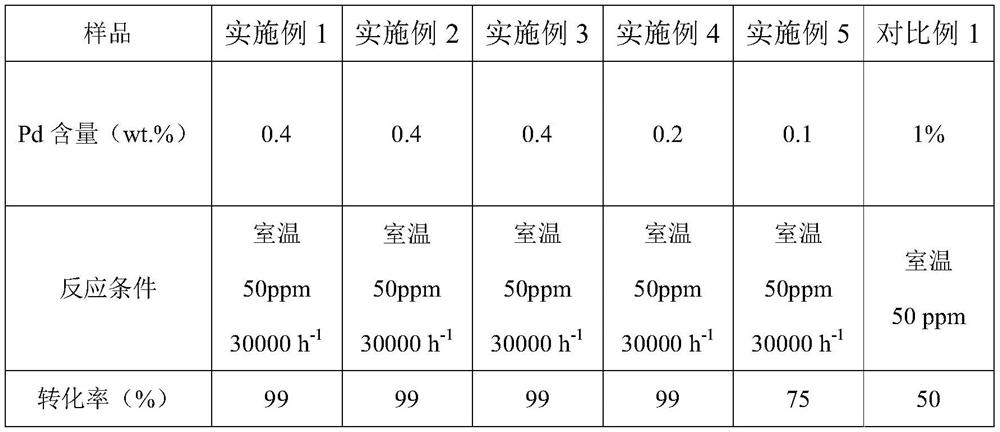

Embodiment 1

[0027] A kind of palladium base catalyst preparation method that is used for thermocatalytic formaldehyde degradation: (1) get 0.5gTiO 2 Place in a fixed-bed reduction reaction tube; (2) rise to 300°C at room temperature at a heating rate of 10°C / min, and carry out hydrogen reduction at different temperatures for 3 hours, and then continue to pass hydrogen to cool naturally to room temperature; (3) absorb Add 0.4ml of 10mg / ml palladium nitrate solution into the three-necked flask, then add pure water, and keep stirring; (4) under stirring, add reduced anatase (TiO 2 ) solid, stirred and reacted for 1h; (5) then added dropwise 1mol / L NaOH solution until the pH of the solution was 10; (6) weighed 0.0071g NaBH 4 Solid, add 10ml pure water to prepare NaBH 4 Solution, dropwise added to the aforementioned solution, continue to stir and react for 2 hours; (7) After the reaction is completed, centrifuge the solution at 8000 rpm for 5 minutes, wash with deionized water, repeat the cen...

Embodiment 2

[0029] A kind of palladium base catalyst preparation method that is used for thermocatalytic formaldehyde degradation: (1) get 0.5gTiO 2 Place in a fixed-bed reduction reaction tube; (2) Rise to 400°C at room temperature at a heating rate of 10°C / min, and carry out hydrogen reduction at different temperatures for 3 hours, and then continue to cool to room temperature naturally with hydrogen; (3) Absorb Add 0.4ml of 10mg / ml palladium nitrate solution into the three-necked flask, then add pure water, and keep stirring; (4) under stirring, add reduced anatase (TiO 2 ) solid, stirred and reacted for 1h; (5) then added dropwise 1mol / L NaOH solution until the pH of the solution was 10; (6) weighed 0.0071g NaBH 4 Solid, add 10ml pure water to prepare NaBH 4 Solution, dropwise added to the aforementioned solution, continue to stir and react for 2 hours; (7) After the reaction is completed, centrifuge the solution at 8000 rpm for 5 minutes, wash with deionized water, repeat the centri...

Embodiment 3

[0031] A kind of palladium base catalyst preparation method that is used for thermocatalytic formaldehyde degradation: (1) get 0.5gTiO 2 Placed in a fixed bed reduction reaction tube; (2) Under the condition of a heating rate of 10 °C / min, the room temperature was raised to 500 °C, and hydrogen reduction was performed at different temperatures for 3 hours, and then continued to cool to room temperature naturally with hydrogen; (3) absorb Add 0.2ml of 10mg / ml palladium nitrate solution into the three-necked flask, then add pure water, and continue to stir; (4) under stirring, add reduced anatase (TiO 2 ) solid, stirred and reacted for 1h; (5) then added dropwise 1mol / L NaOH solution until the pH of the solution was 10; (6) weighed 0.0071g NaBH 4 Solid, add 10ml pure water to prepare NaBH 4 Solution, dropwise added to the aforementioned solution, continue to stir and react for 2 hours; (7) After the reaction is completed, centrifuge the solution at 8000 rpm for 5 minutes, wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com