Visual positioning welding assembly method

A visual positioning and welding technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of positioning reference wear and positioning, takt loss, high energy consumption, and achieve the goal of reducing import costs, reducing investment, and improving utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

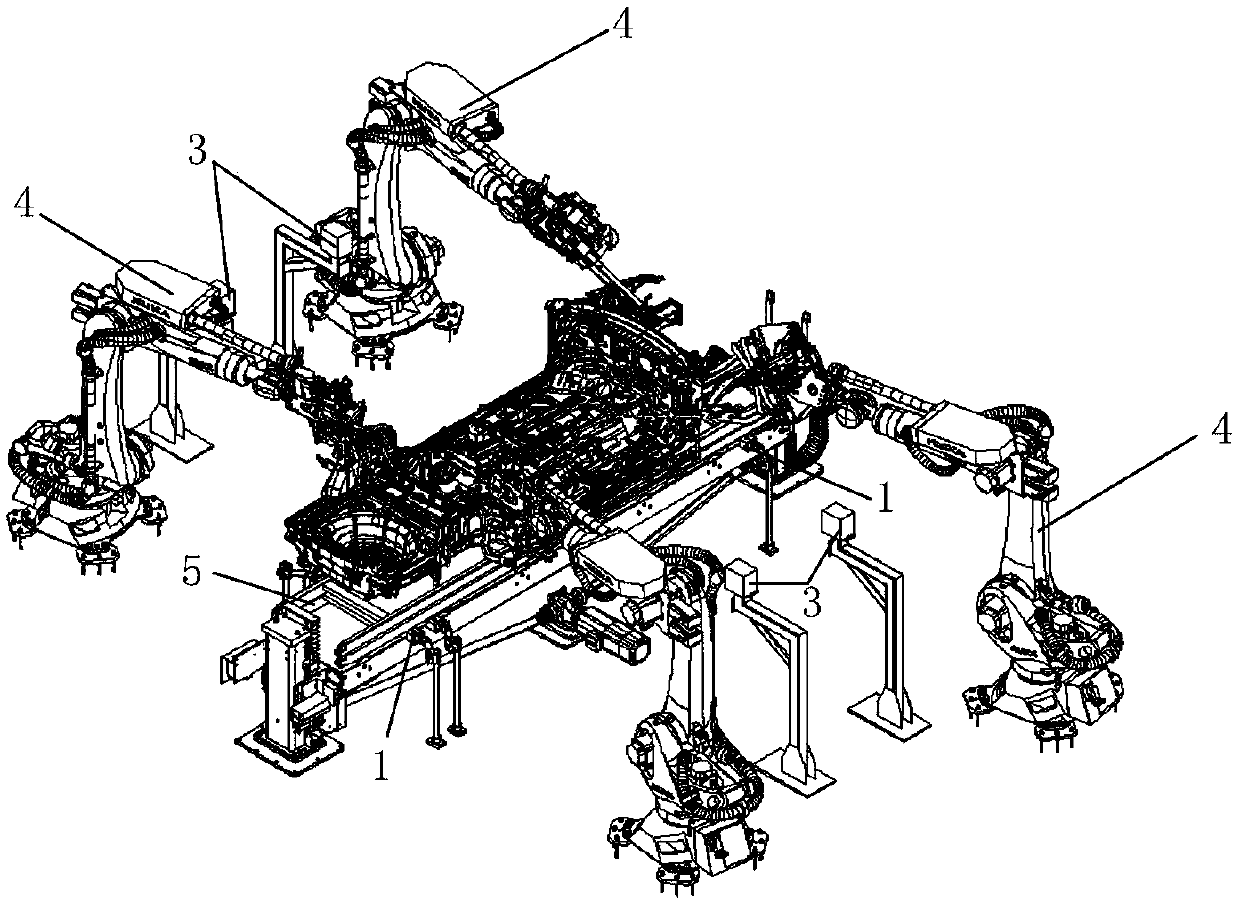

Embodiment 1

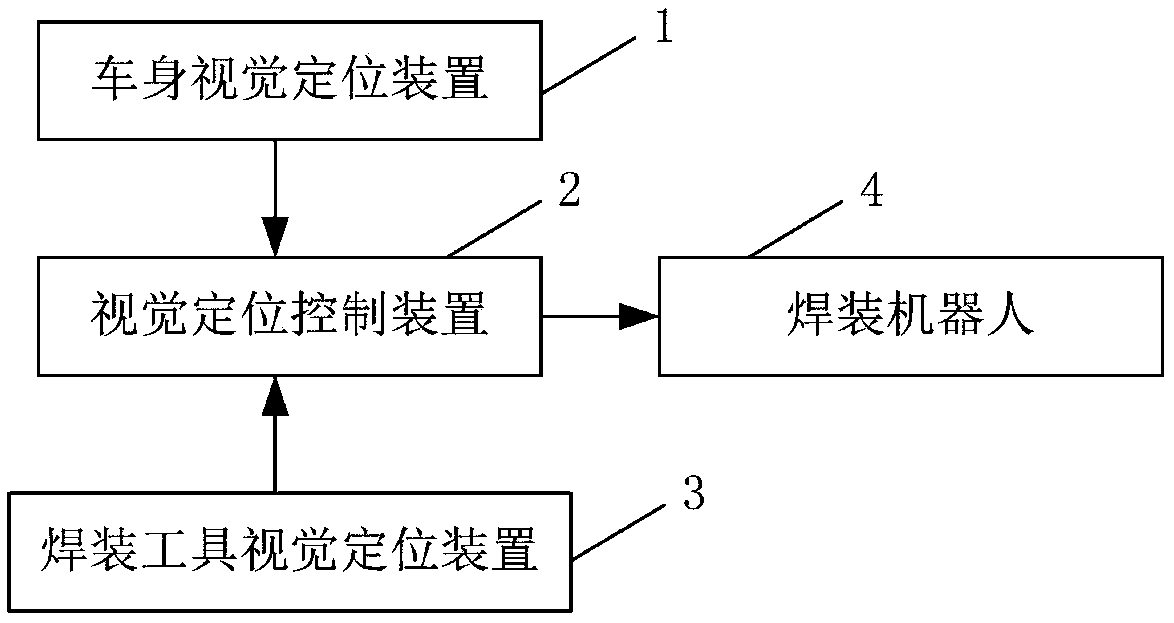

[0029] The visual positioning and welding system provided by the embodiment of the first aspect of the present invention optimizes the positioning mode of the welding production line, uses machine vision technology to position the vehicle body, and guides the welding robot 4 to perform subsequent processes, so that the same welding The assembly line is equipped with fast and flexible switching of any model, which avoids the development and processing of many non-standard fixtures and fixtures, and uses non-contact positioning to avoid deviations in body size caused by repeated positioning, reducing the introduction cost of model upgrades, and reducing the introduction of subsequent projects At the same time, improve the utilization rate of the beat and create more value for the enterprise.

[0030] In the optional solution of this embodiment, further, the visual information of the positioning point includes the deviation value of the position of the vehicle body and the deforma...

Embodiment 2

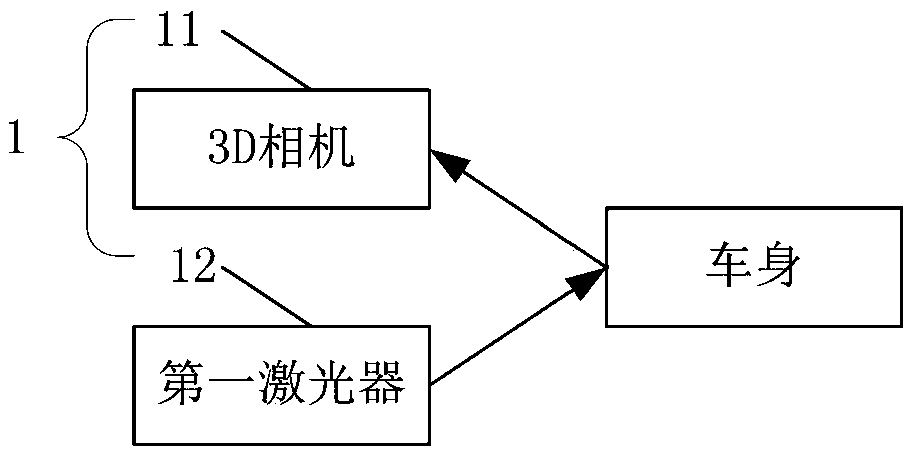

[0040] The embodiment of the second aspect of the present invention provides a visual positioning welding method, including: the first visual sensor 11 collects the visual information of the positioning point of the vehicle body, wherein the visual information of the positioning point includes the deviation value of the position of the vehicle body and the deformation information of the positioning point The second visual sensor 21 collects the tool vision information of the welding robot 4, wherein the tool vision information includes the welding robot 4 position information and the welding tool position information on the welding robot 4; the visual positioning control device 2 receives the positioning point vision information and tool vision information, and control the welding robot 4 to adjust the position and processing path of the welding tool according to the visual information of the positioning point and the tool vision information, so as to guide the welding robot 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com