Composite material, preparation method and application thereof

A technology of composite materials and composite material layers, which is applied in the field of composite materials and its preparation, can solve the problems of physical injuries of workshop workers, and achieve the effects of ensuring physical health and huge social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

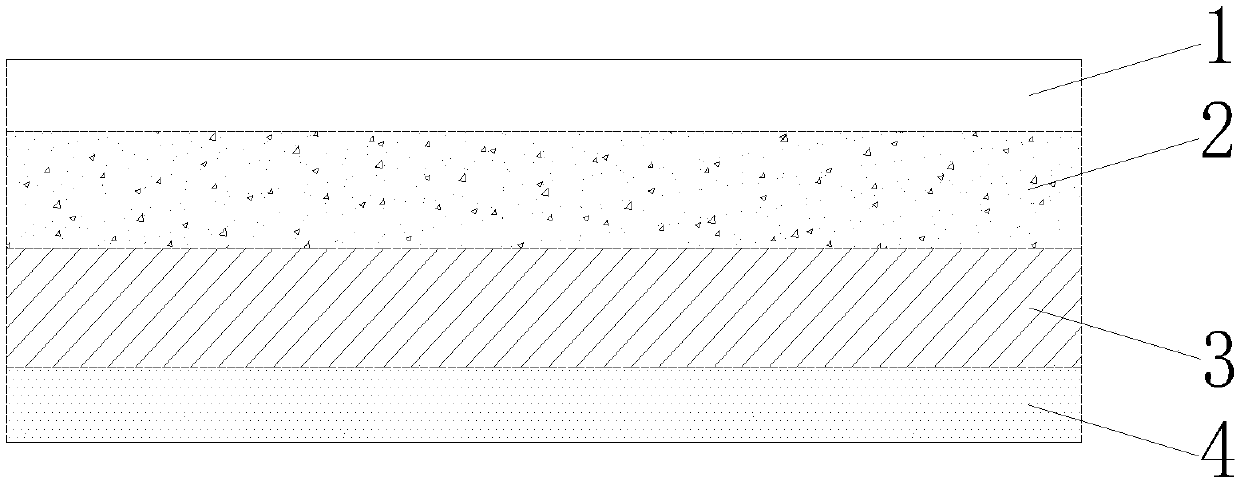

[0025] The invention relates to a composite material, which is sequentially composed of a barrier layer, a nano-selenium composite material layer, a water-absorbing layer, and a contact layer from top to bottom;

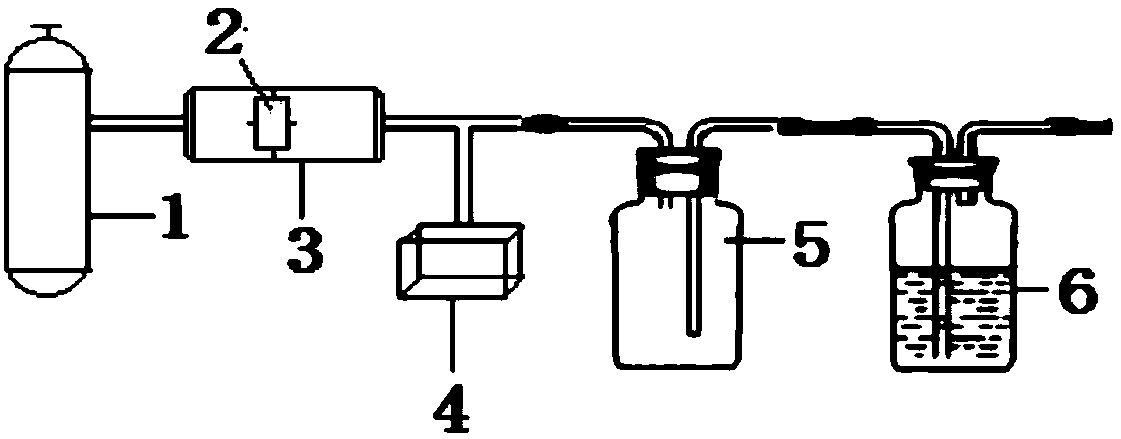

[0026] The material of the barrier layer is PVC, and the thickness is 0.5mm; the percentage of the mass of each component of the nano-selenium composite material layer in the total mass is: 70% of nano-scale activated carbon; 10% of nano-selenium; 20% of hot-melt adhesive, wherein the The hot melt adhesive is polyurethane. Under the temperature condition of 200℃, the specific surface area is 500m 2 Add nano-selenium with a particle size of 20nm and a binder into / g of nano-scale activated carbon and stir and mix for 10 minutes. After fully mixing, the nano-selenium composite material with a thickness of 1.5mm is obtained through coating film formation, cooling, compounding, and winding processes. layer; the water-absorbing layer is made of cross-shaped hollow polyes...

Embodiment 2

[0034] The invention relates to a composite material, which is sequentially composed of a barrier layer, a nano-selenium composite material layer, a water-absorbing layer, and a contact layer from top to bottom;

[0035] The material of the barrier layer is PTEE, and the thickness is 1mm; the percentage of the mass of each component of the nano-selenium composite material layer in the total mass is: 80% of nano-scale activated carbon; 10% of nano-selenium; 10% of hot-melt adhesive, wherein the heat The melt adhesive is polystyrene. Under the temperature condition of 150℃, the specific surface area is 1000m 2 Add nano-selenium with a particle size of 40nm and an adhesive in / g nano-scale activated carbon and stir and mix for 15 minutes. The material of the layer is cross-shaped hollow polyester fiber with a thickness of 1 mm; the material of the contact layer is non-woven fabric with a thickness of 1 mm.

[0036] The four-layer structure in the composite material of the prese...

Embodiment 3

[0043] The invention relates to a composite material, which is sequentially composed of a barrier layer, a nano-selenium composite material layer, a water-absorbing layer, and a contact layer from top to bottom;

[0044] The material of the barrier layer is FEP, and the thickness is 1.5mm; the percentage of each component mass of the nano-selenium composite material layer in the total mass is: 90% of nano-scale activated carbon; 5% of nano-selenium; 5% of hot-melt adhesive, wherein the The hot melt adhesive is polyacrylate. Under the temperature condition of 100℃, the specific surface area is 1500m 2 Adding nano-selenium and binder with a particle size of 60nm in / g nano-scale activated carbon and stirring and mixing for 20min, after fully mixing, obtain a nano-selenium composite material layer with a thickness of 0.5mm through coating film formation, cooling, compounding, and winding processes; The absorbent layer is made of cross-shaped hollow polyester fiber with a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com