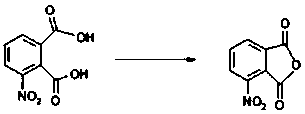

Preparation method of 3-nitrophthalic anhydride

A technology of nitrophthalic anhydride and nitrophthalic acid, which is applied in the field of preparation of 3-nitrophthalic anhydride, can solve the problems of low output, large manpower, material resources and high cost, and achieve The effect of low cost, high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation method of 3-nitrophthalic anhydride: 212 grams of 3-nitrophthalic acid is placed in the reaction solvent, the reaction solvent is 300 grams of toluene and 50 grams of acetic acid, then add 6 grams of p-toluenesulfonic acid, Raise the temperature to 100-150°C and react for 4-12 hours, take a sample and detect by HPLC that the 3-nitrophthalic acid content is less than 1%, and stop heating; the obtained substance is removed under the condition of negative pressure -0.08- -0.098Mpa toluene and acetic acid , p-toluenesulfonic acid to obtain 184.5 grams of 3-nitrophthalic anhydride, with a content of 98% and a yield of 95.1%.

Embodiment 2

[0018] The preparation method of 3-nitrophthalic anhydride: 212 grams of 3-nitrophthalic acid is placed in the reaction solvent, the reaction solvent is 400 grams of toluene and 100 grams of acetic acid, then add 4 grams of p-toluenesulfonic acid, Raise the temperature to 100-150°C and react for 4-12 hours, take a sample and detect by HPLC that the 3-nitrophthalic acid content is less than 1%, and stop heating; the obtained substance is removed under the condition of negative pressure -0.08- -0.098Mpa toluene and acetic acid , p-toluenesulfonic acid to obtain 182 grams of 3-nitrophthalic anhydride, with a content of 98% and a yield of 93.8%.

Embodiment 3

[0020] The preparation method of 3-nitrophthalic anhydride: 212 grams of 3-nitrophthalic acid is placed in the reaction solvent, the reaction solvent is 350 grams of toluene and 55 grams of acetic acid, then add 5 grams of p-toluenesulfonic acid, 5 grams of tetrabutylammonium bromide, heat up to 100-150°C and react for 4-12 hours, take a sample and stop heating when the content of 3-nitrophthalic acid is less than 1% by HPLC; Toluene, acetic acid and p-toluenesulfonic acid were removed under the condition of 0.098Mpa to obtain 186 grams of 3-nitrophthalic anhydride with a content of 97.5% and a yield of 95.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com