Waste rubber low-temperature regeneration equipment

A technology of low-temperature regeneration and waste rubber, applied in the direction of plastic recycling, recycling technology, etc., can solve problems such as atmospheric environmental pollution and safety hazards, and achieve the effects of environmental friendliness, low production cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

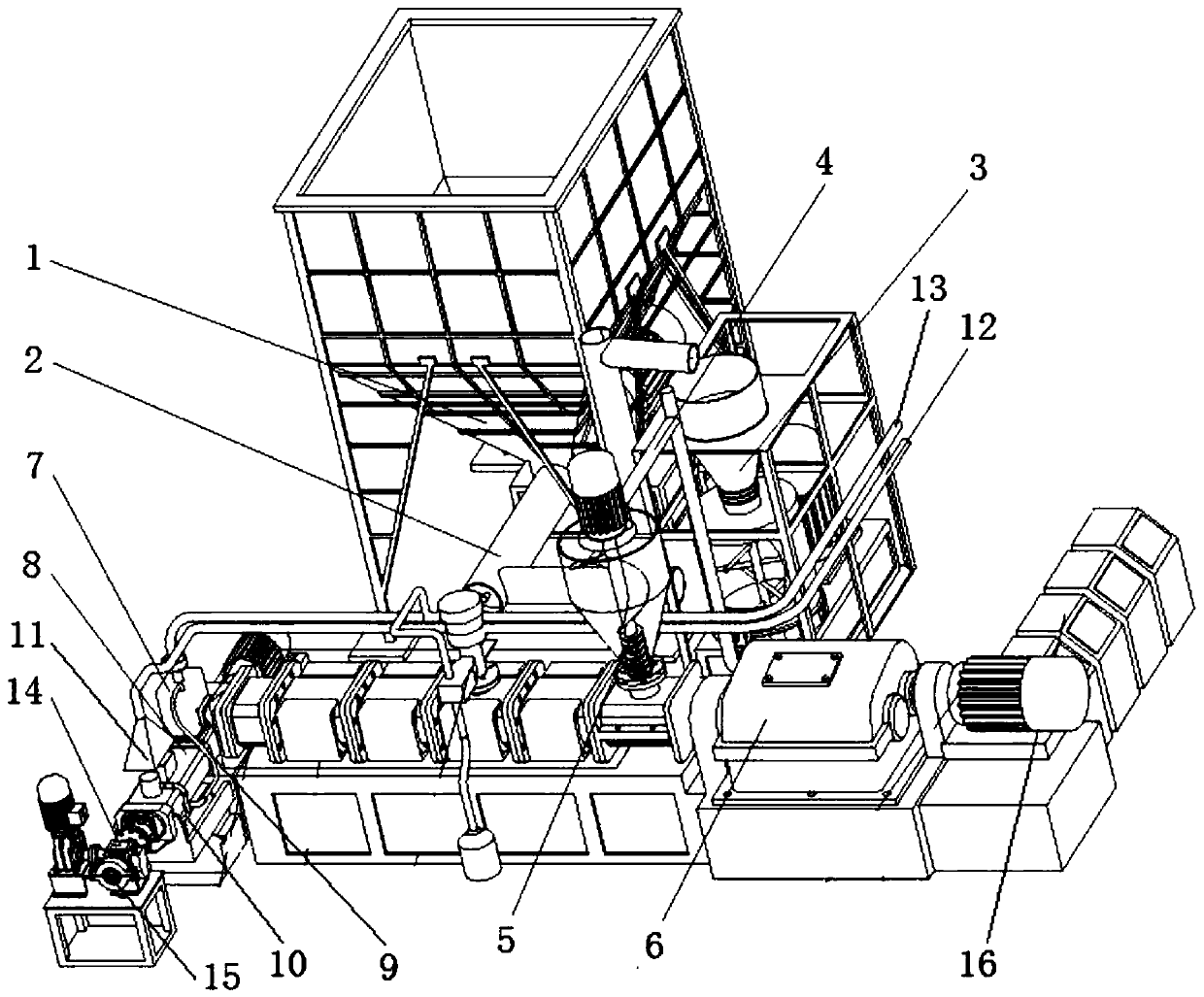

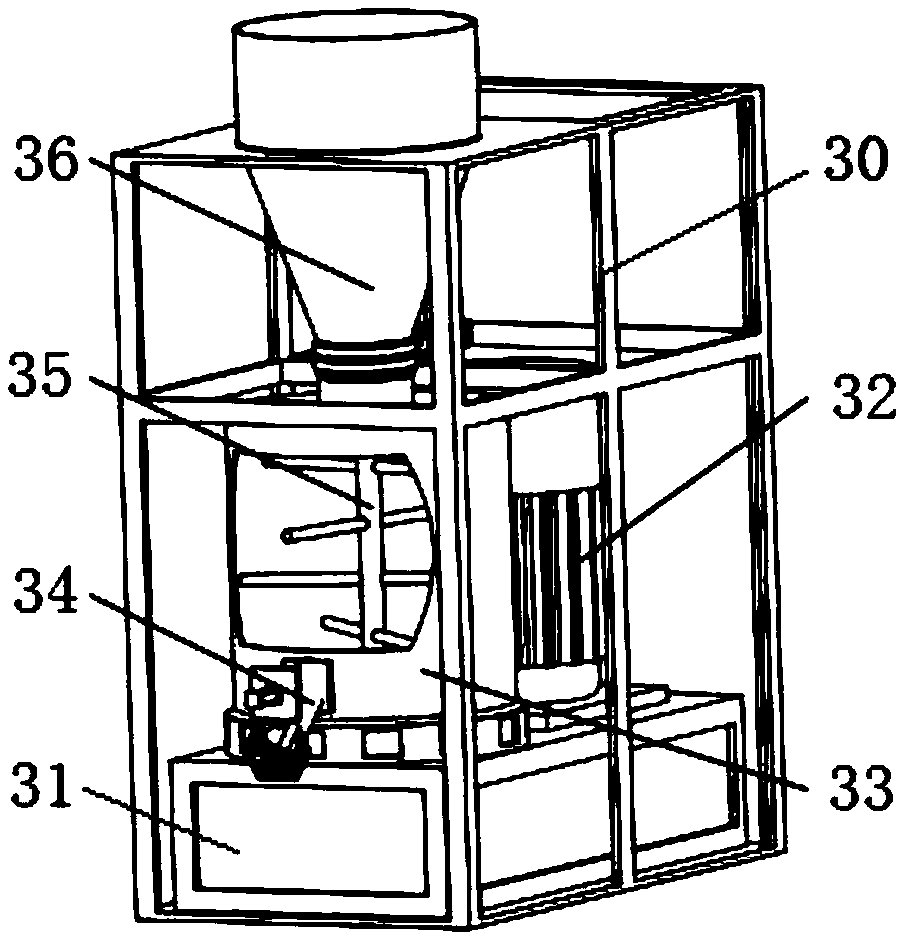

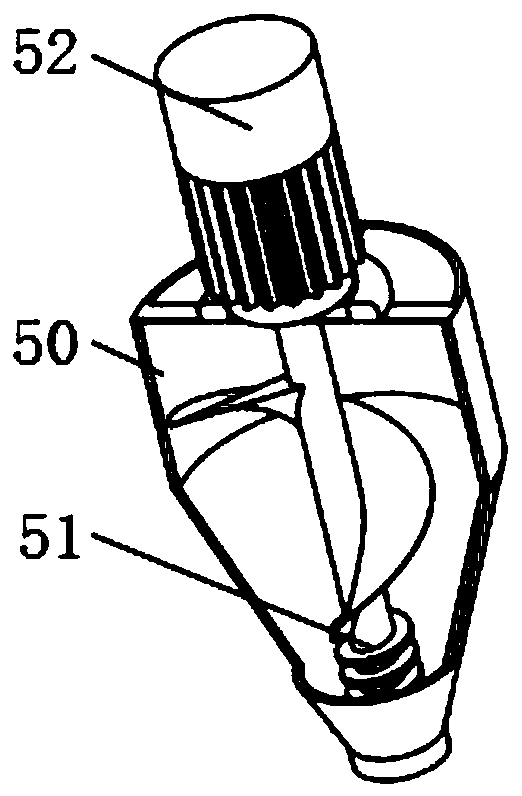

[0021] The main structure of the waste rubber low-temperature regeneration equipment involved in this embodiment includes a rubber powder silo 1, a No. 1 screw feeder 2, a high-low speed premixing mixer 3, a No. 2 screw feeder 4, a feeder 5, and a desulfurizer 6. Cooling buffer chamber 7, extruder 8, cooling water spray pipe 9, water filter port 10, exhaust port 11, No. 1 waste gas collection pipe 12, No. 2 waste gas collection pipe 13, high-pressure gear pump 14, discharge port 15 and mold temperature machine 16; the bottom of the rubber powder silo 1 with a funnel structure is connected to the No. The outlet of the mixer 3 is connected to the No. 2 screw feeder 4, and a feeder 5 is arranged below the outlet of the No. 2 screw feeder 4. The outlet of the feeder 5 is flange-connected with the inlet of the desulfurizer 6, and the desulfurization The outlet of the machine 6 is connected with the cooling buffer bin 7 of the inner hollow structure, and an extruder 8 is arranged be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com