Preparation method of composite bacterial agent for water purification

A compound bacterial agent and water purification technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve problems such as antibiotic residues and food safety, reduce waste of resources, and improve the breeding environment , Excellent degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

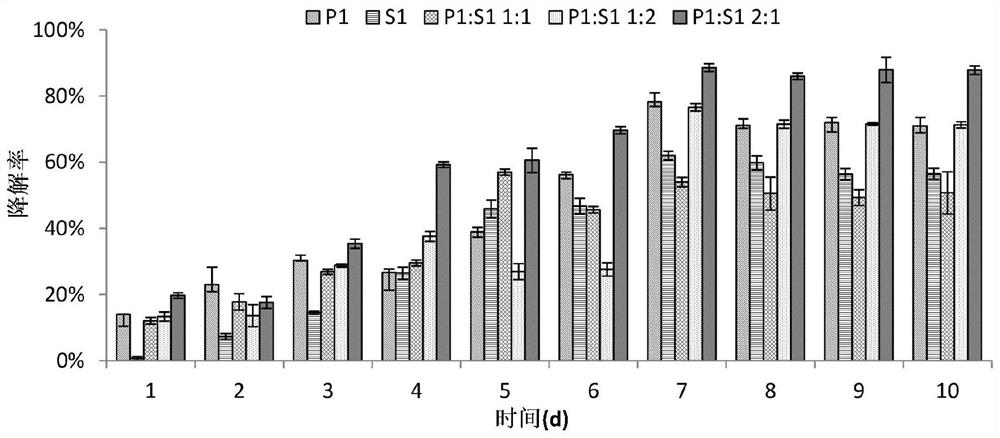

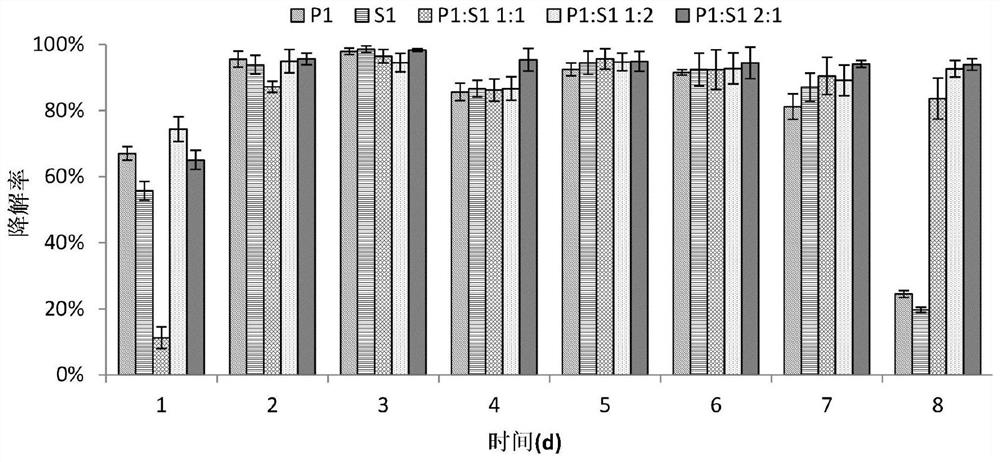

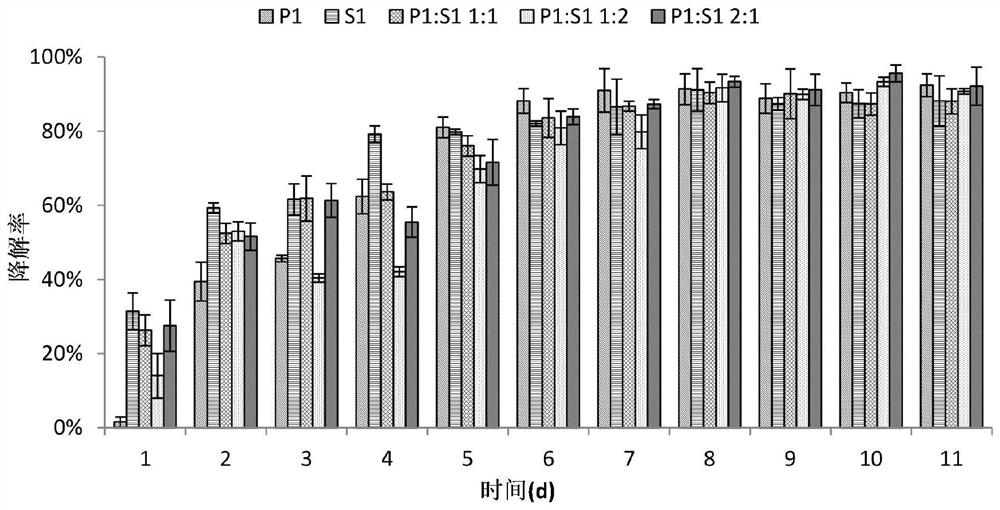

Embodiment 1

[0030] (1) Activated strain

[0031] Prepare LB and MRS solid medium, make slant and flat plate, take out the glycerol tubes of the experimental strains Lactobacillus plantarum and Bacillus sime in the refrigerator at -80°C and thaw naturally, mark the slope with a bamboo stick, and culture at 30°C. After 3-7 days of cultivation, they were stored in a 4°C refrigerator for later use.

[0032] (2) Propagation of strains

[0033] Pick the activated experimental strain with a bamboo stick, inoculate it in LB or MRS liquid medium according to the inoculum size of 8%, and cultivate it on a constant temperature shaker at 30°C for 24 hours to obtain the Lactobacillus plantarum strain and Bacillus Simeum liquid;

[0034] (3) Preparation of bacterial suspension

[0035] Pour the liquid of Lactobacillus plantarum and Bacillus sime into a centrifuge tube at a ratio of 2:1, centrifuge at 10000r / min for 10min, mix it evenly with sterile water, prepare a uniformly distributed bacterial s...

Embodiment 2

[0037] The difference between this example and Example 1 is that Lactobacillus plantarum and Bacillus siemum are mixed in a ratio of 1:1 to prepare a composite microbial suspension.

Embodiment 3

[0039] The difference between this example and Example 1 lies in that Lactobacillus plantarum and Bacillus siemum are mixed in a ratio of 1:2 to prepare a composite microbial suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com