Semi-rigid substratum anti-crack pavement structure suitable for cold areas and construction method

A technology for semi-rigid base and cold area, applied in the field of semi-rigid base crack-resistant pavement construction, it can solve the problems of destroying the integrity and continuity of the pavement structure, weakening the structural strength, and degrading the driving quality of vehicles, and achieves a good crack resistance effect and Economic benefits, slow scaling, and the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

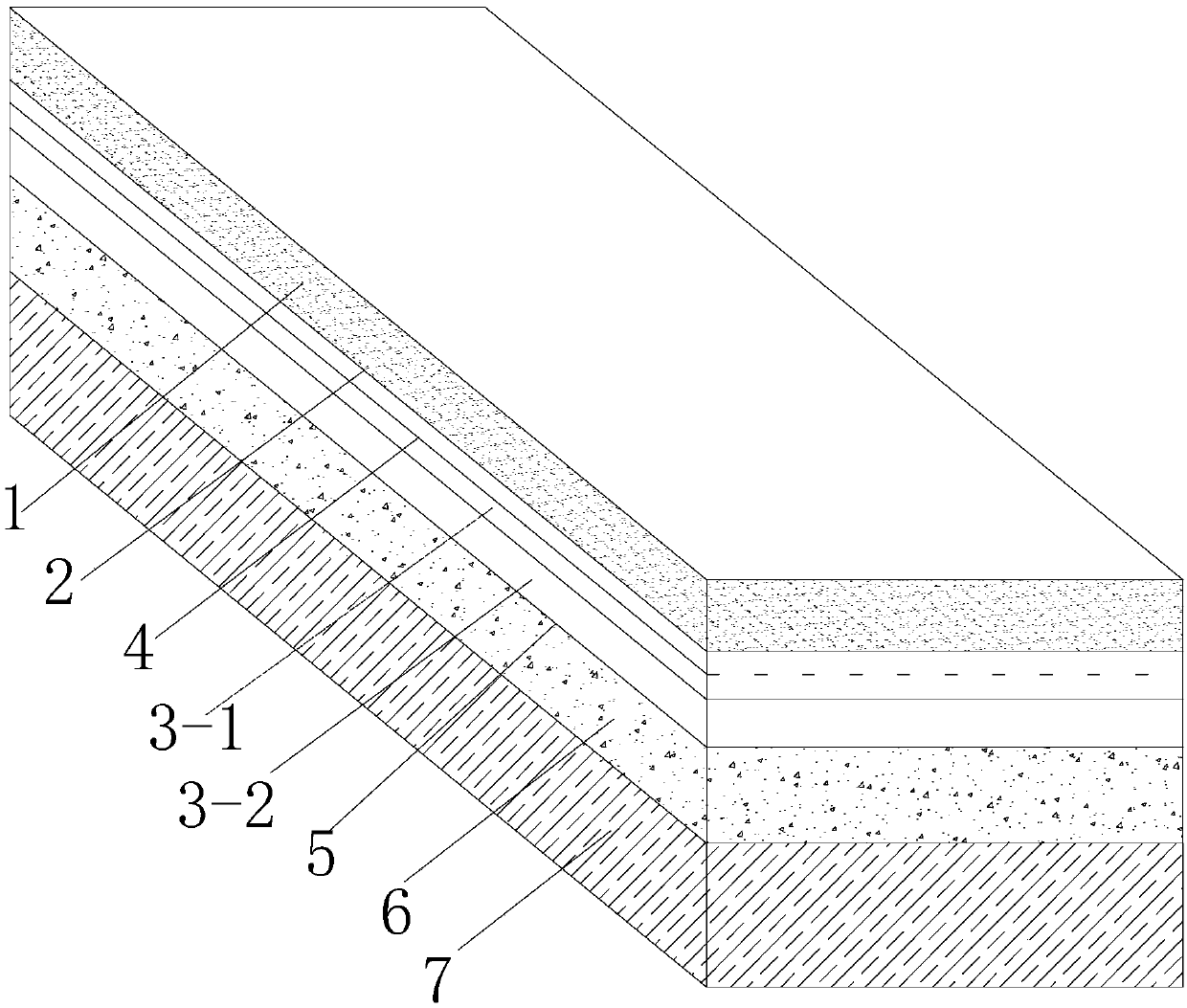

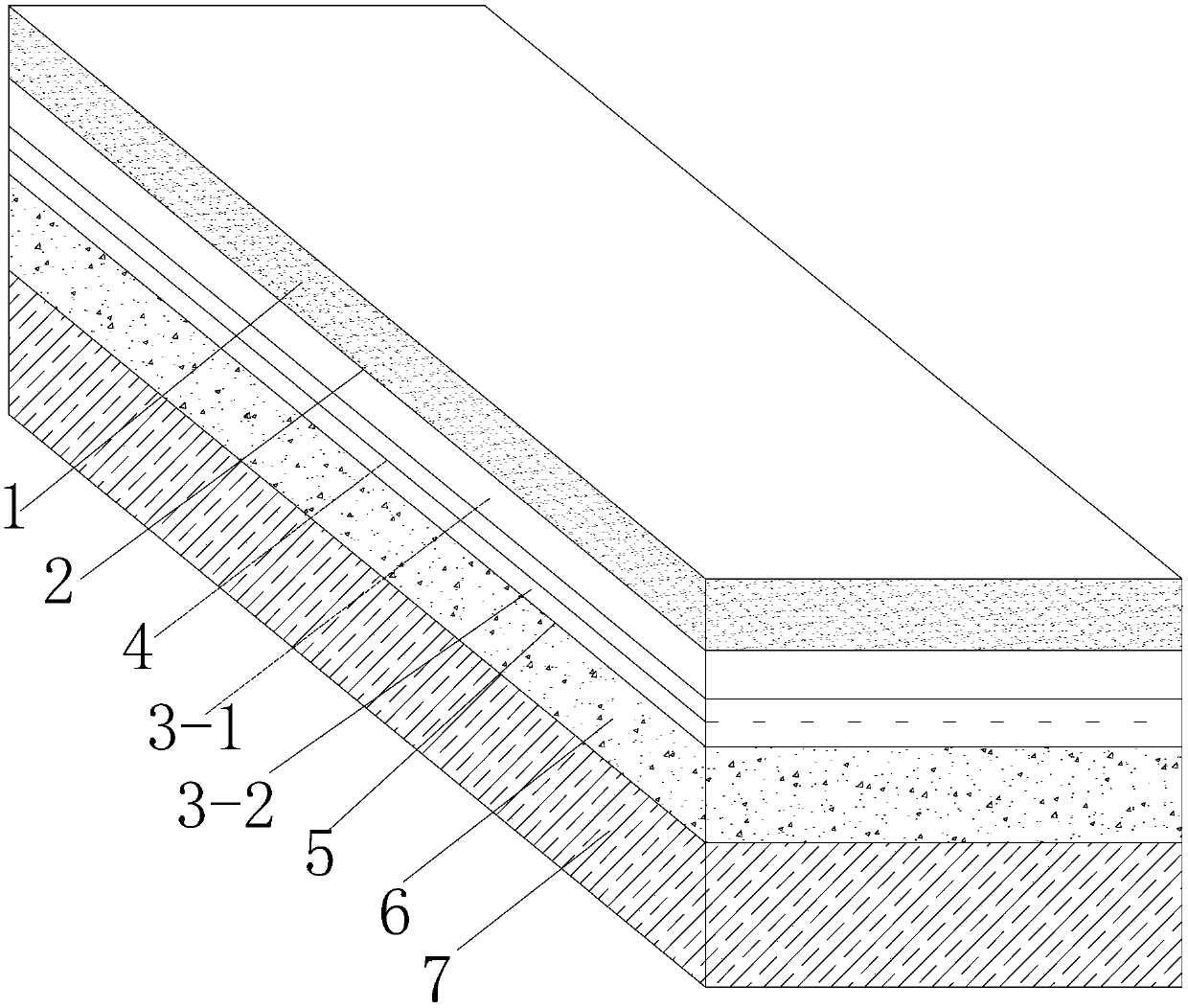

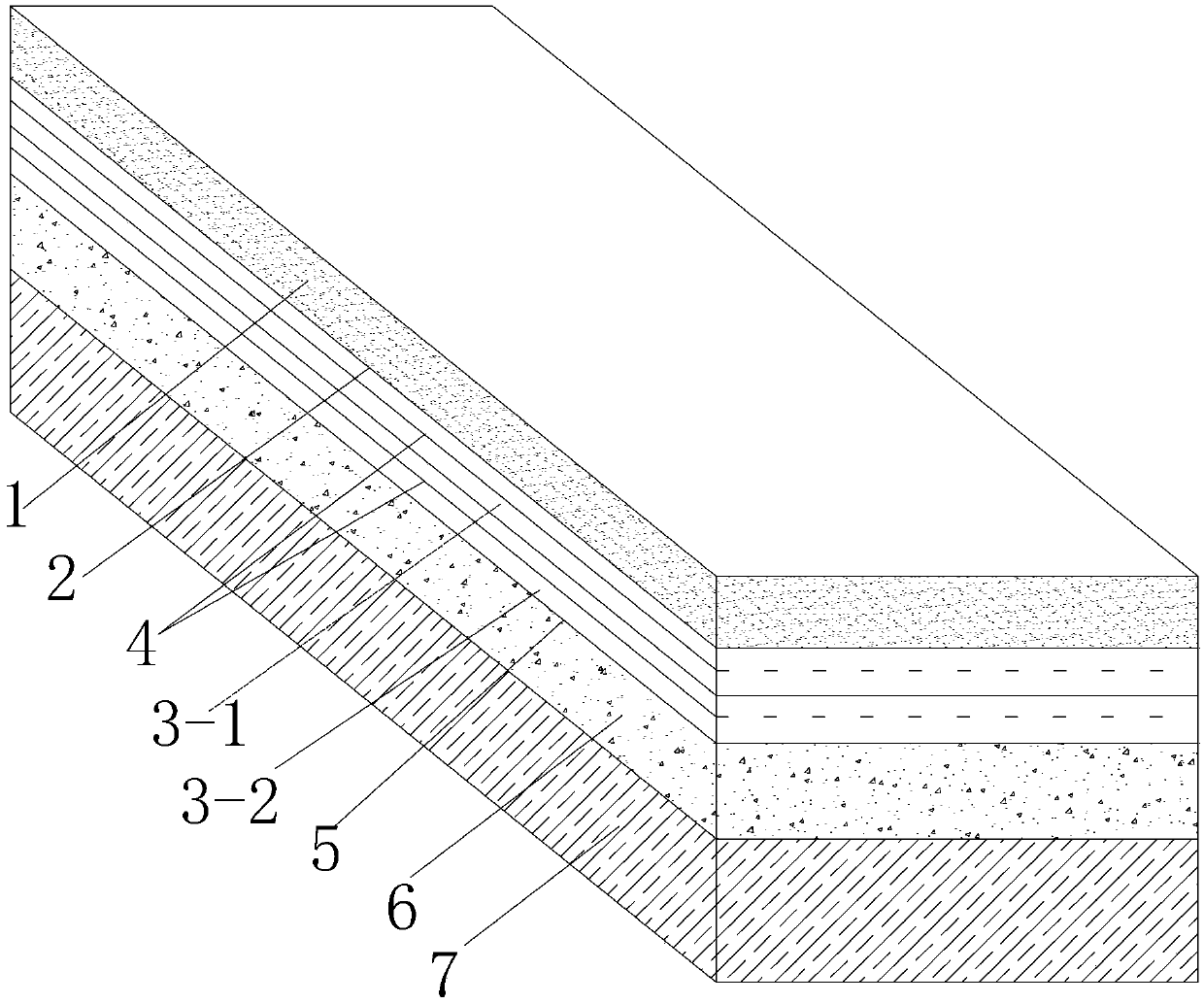

[0040] Such as Figure 1 to Figure 3 As shown, the anti-cracking pavement structure of the semi-rigid base course in the present invention is suitable for cold areas, including a semi-rigid base course 6, a semi-rigid base course 3, and a surface course 1 laid sequentially on the subgrade 7 from bottom to top, and a semi-rigid subbase course 6 and the semi-rigid base 3 are laid with a first permeable layer 5, between the semi-rigid base 3 and the surface layer 1 a protective layer 2 is laid, and a reinforcement layer is laid in the semi-rigid base 3, and the reinforcement layer and the semi-rigid base 3 is constructed as a whole, the reinforcement layer includes a plurality of basalt fiber belts 4 laid in parallel and equidistant along the length direction of the pavement, the semi-rigid base 3 includes a semi-rigid lower base 3-2 and a semi-rigid lower base 3-2 3-1 on the semi-rigid upper base.

[0041] It should be noted that, according to the height of the crack-resistant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com