A magnesium alloy casting and rolling fluid transfer system device

A system device and magnesium alloy technology are applied in the field of magnesium alloy sheet and strip casting and rolling equipment, which can solve the problems of inconvenient repair, easy formation of segregation, explosion, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

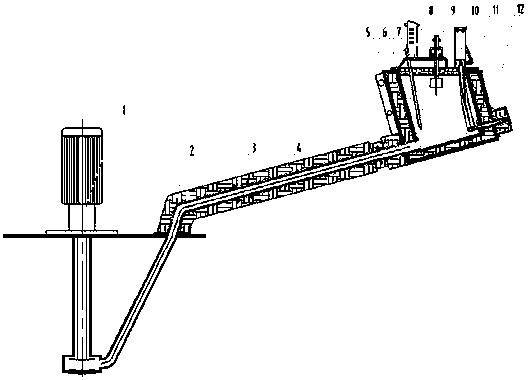

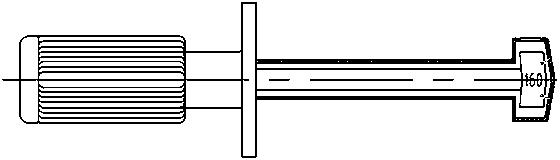

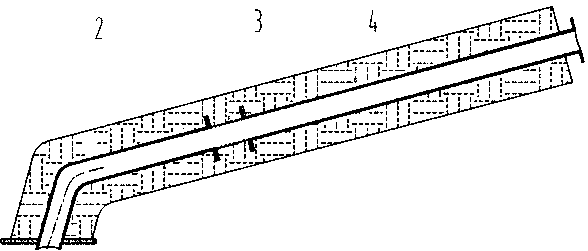

[0021] refer to figure 1 As shown, at first, open the switch of the protective gas input channel 8 installed at the top cover 6 of the front box, and simultaneously open the switches of the liquid transfer pipe 2 and the heating device 4 and 11 of the front box 5, and the transmission pipeline and the front box 5 leading to the protective gas will be connected. The box is preheated to 680-700°C, and the nozzle and casting roll are preheated to the set target temperature. After the preheating of the front box system is completed, the outlet plug device 10 in the front box is kept in a sealed state, and under the protective gas, the servo pump 1 with the lower end of the tapered cavity is used to transfer the refined, ventilated slag blowing, The magnesium alloy liquid after standing still is transported to the front box 5 through the liquid transfer pipeline 2, and the temperature detector 7 in the front box in the temperature linkage control described in the above-mentioned in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com