Construction process of pavement base layer made of carbide slag and fly ash stabilized coal gangue aggregate

A technology of pavement base and construction technology, which is applied in the direction of roads, roads, sustainable waste treatment, etc., can solve the problems that the compressive strength cannot meet the specification requirements, the long-term strength cannot be improved, and the strength formation speed is slow, so that the construction technology is easy to master , significant economic and social benefits, and the effect of increased strength in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The calcium carbide slag fly ash stabilized gangue aggregate pavement base of the present invention comprises the following materials in parts by weight: 5-15 parts of carbide slag, 10-20 parts of fly ash, 70-80 parts of coal gangue aggregate, and 7-14 parts of water parts, 10-30 parts of papermaking wastewater. The quality of calcium carbide slag, fly ash, coal gangue aggregate and water, and the gradation of coal gangue aggregate meet the requirements of (JTJ 034-2000) "Technical Specifications for Construction of Highway Pavement Base", and the minimum concentration of soluble matter in papermaking wastewater is 3wt%, the maximum water content of carbide slag is 10wt%.

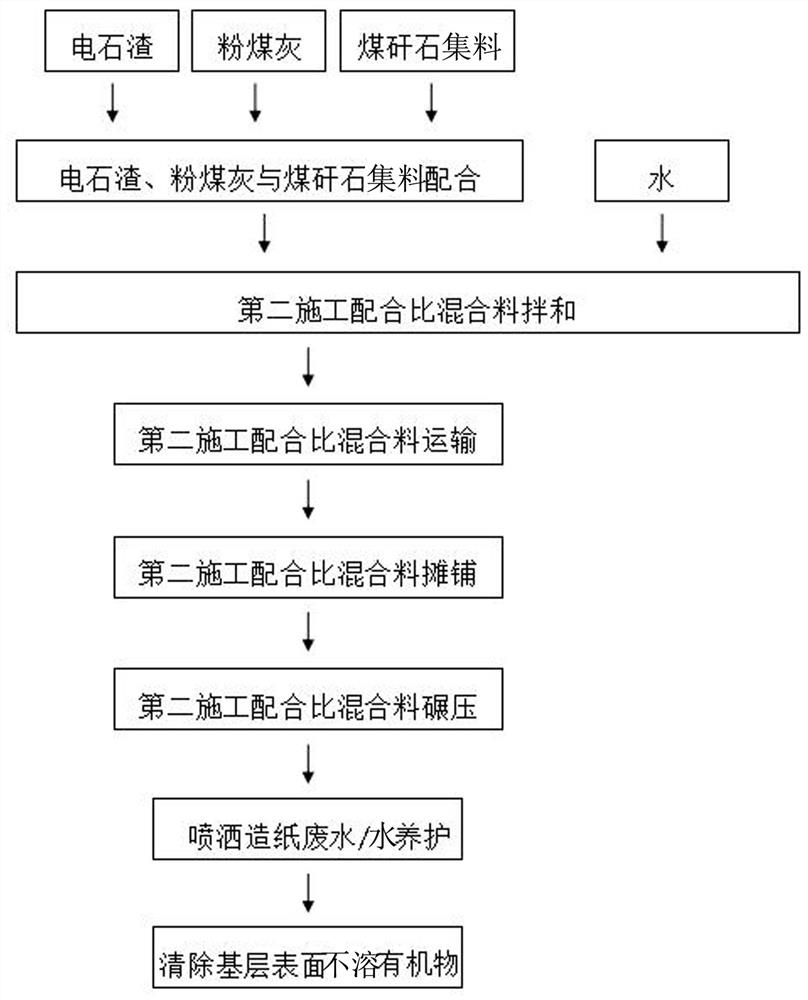

[0044] The construction technology of the above-mentioned pavement base, such as figure 1 As shown, specifically:

[0045] The first step is to design the mass mix ratio before construction, specifically:

[0046] 1. Determine the mix ratio of the first design quality

[0047] 1) Preparation of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com