Voltage regulatable anisotropic magnetoresistive sensor and manufacturing method thereof

An anisotropic magnetic and sensor technology, which is applied in the fields of magnetic field controlled resistors, manufacturing/processing of electromagnetic devices, parts of electromagnetic equipment, etc. Large-scale industrial production and application, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

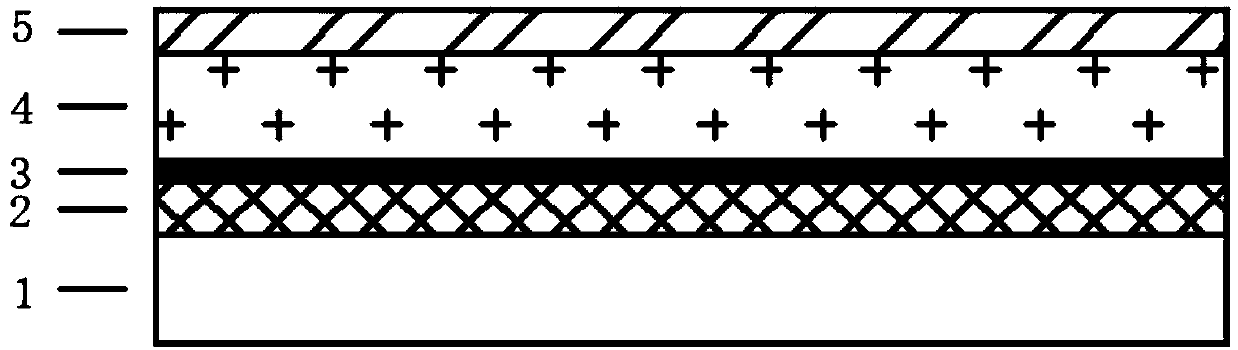

[0021] Such as figure 1 As shown, it is a schematic structural diagram of an anisotropic magnetoresistive sensor with adjustable voltage provided by the embodiment of the present invention; the anisotropic magnetoresistive sensor of the embodiment is a single crystal silicon substrate 1, a non-magnetic metal An oxide film 2, a magnetic control layer 3, a magnetic response layer 4 and a non-magnetic heavy metal film 5. Among them, the interface between the magnetic control layer 3 and the non-magnetic metal oxide film 2 undergoes an oxidation reaction of oxygen ion migration, and the 3d orbital electrons of the magnetic atoms are hybridized with the 2p orbital electrons of the oxygen ions, so that the magnetic control layer 3 is in a ferromagnetic state. In the transition stage of the ferromagnetic state, there is an exchange coupling effect with the magnetic response layer 4 . When an out-of-plane voltage is applied, the degree of oxidation reaction between the magnetic atoms...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com