Pneumatic flexible electrode heating clamping device for aluminum alloy member and in-mold quenching forming method

A technology of aluminum alloy components and flexible electrodes, which is applied in the field of aluminum alloy hot forming, can solve the problems of sheet metal distortion, quenching stress and reduce the dimensional accuracy of formed parts, etc., and achieve the effects of preventing oxidation, uniform force, and ensuring forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

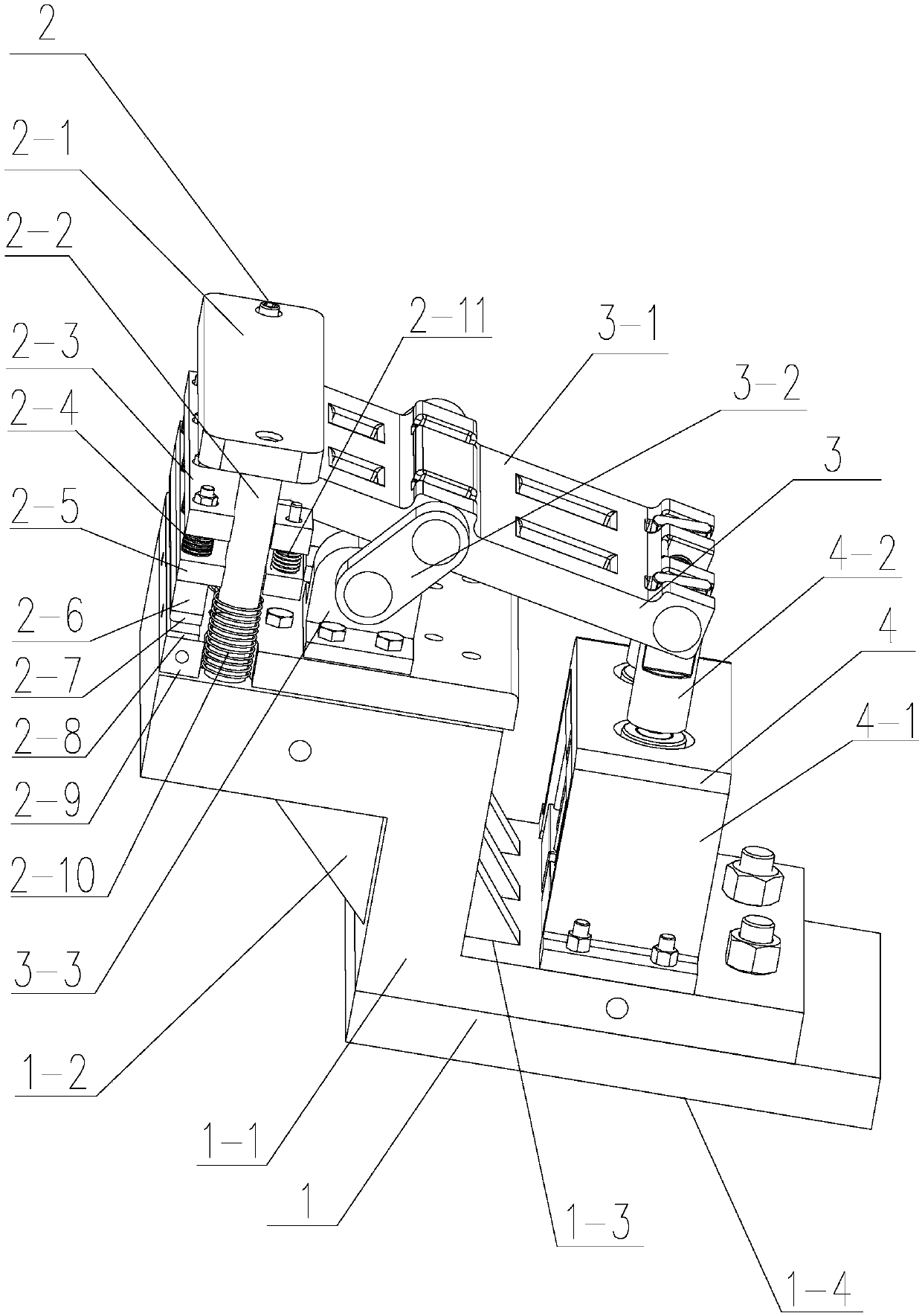

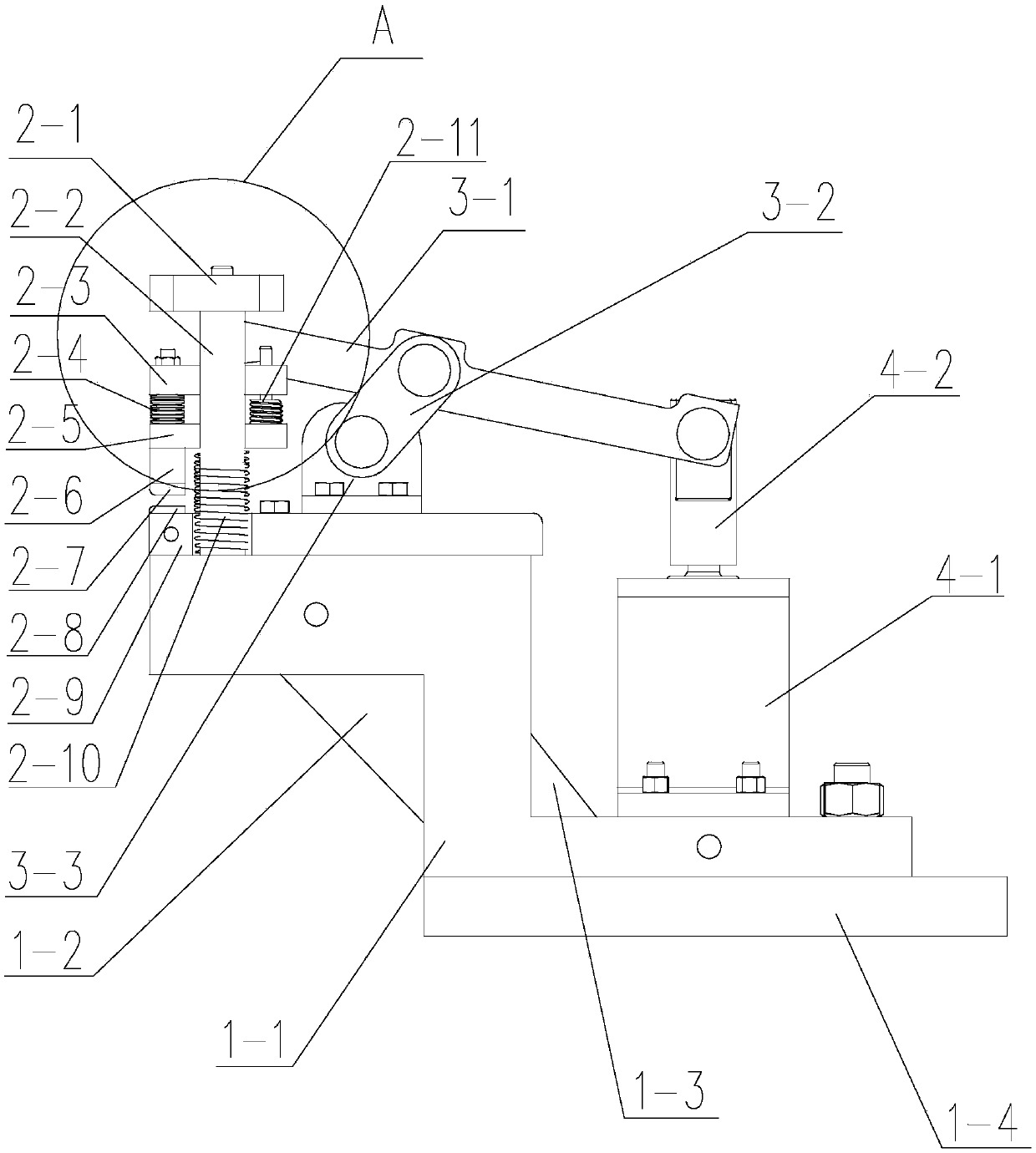

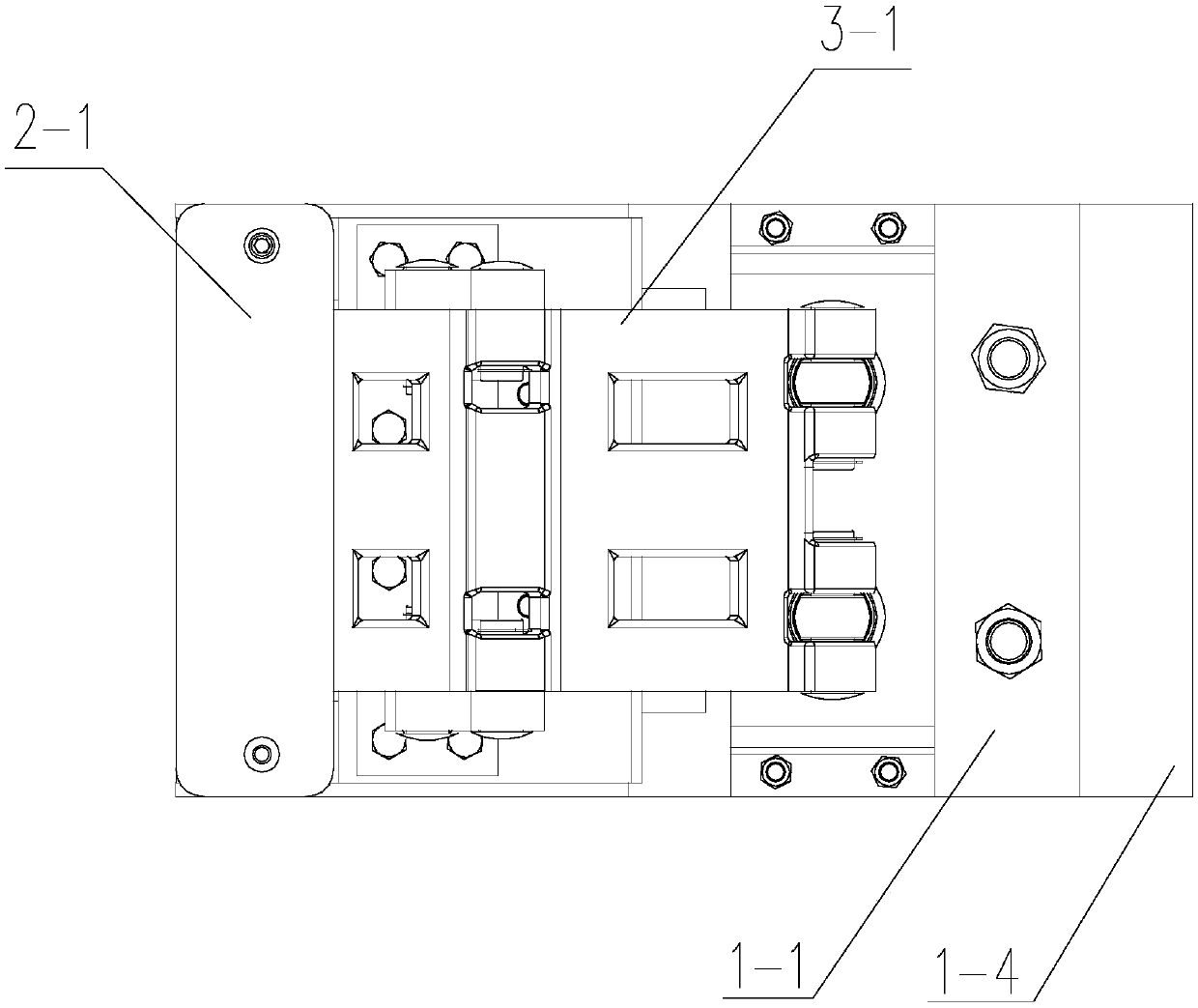

[0040] Specific implementation mode one: combine Figure 1-14 This embodiment is described. In this embodiment, a pneumatic flexible electrode heating and clamping device for an aluminum alloy component is described. The pneumatic flexible electrode clamping unit for an aluminum alloy component includes at least a pair of heating and clamping units. The unit includes a supporting assembly 1, a clamping assembly 2, a connecting rod assembly 3 and a pneumatic assembly 4, the clamping assembly 2 and the pneumatic assembly 4 are installed on the supporting assembly 1, and the connecting rod assembly 3 is realized by driving the pneumatic assembly 4 The up and down movement of the clamping assembly 2;

[0041] The supporting assembly 1 includes a supporting plate 1-1, and the clamping assembly 2 includes a guide post fixing plate 2-1, a guide post 2-2, an upper sliding connection plate 2-3, a disc spring 2-4, a lower sliding connection Plate 2-5, insulating plate 2-6, pressing pla...

specific Embodiment approach 2

[0046] Specific implementation mode two: combination figure 1 , figure 2 or Figure 12 Describe this embodiment, the pneumatic assembly 4 described in this embodiment includes a pneumatic cylinder 4-1 and a cylinder extension 4-2, and the bottom of the cylinder extension 4-2 is connected to the bottom of the cylinder extension 4-2. -1 top threaded connection, the top of the cylinder overhang 4-2 is connected with the rear part of the movable upper pressing plate 3-1 by pin shaft and rotation. Other compositions and connections are the same as in the first embodiment.

[0047] Specific implementation mode three: combination figure 2 or Figure 4 Describe this embodiment, the support plate 1-1 in this embodiment has three sections, the first section is the upper horizontal plate, the second section is the vertical plate and the third section is the lower horizontal plate, the whole is Z-shaped arrangement, other components and The connection relationship is the same as th...

specific Embodiment approach 7

[0053] Specific implementation mode seven: combination Figure 11 or Figure 12 To illustrate this embodiment, the current heating control system 5 in this embodiment also includes an integrated power supply 5-4, the integrated power supply 5-4 is composed of N sub-power supplies, each sub-power supply is respectively connected to a pair of heating clamping units, and The overall integrated controller 5-1 controls the opening and closing of each sub-power supply respectively. Other compositions and connections are the same as those in Embodiment 1, 2, 3, 4, 5 or 6.

[0054] Specific implementation mode eight: combination Figure 7 To describe this embodiment, through holes are provided on the front side of the electrode plate 2-9 in this embodiment, and the material of the electrode plate 2-9 is pure copper. Other compositions and connections are the same as those in Embodiment 1, 2, 3, 4, 5, 6 or 7.

[0055] In this embodiment, holes are opened at the front ends of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com