A method for preparing diisononyl phthalate molecularly imprinted microspheres

A technology of diisononyl phthalate and molecularly imprinted microspheres, which is applied in the field of molecularly imprinted polymer preparation, can solve the problems of many interference factors and unfavorable detection, and achieve the effect of reducing matrix interference and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

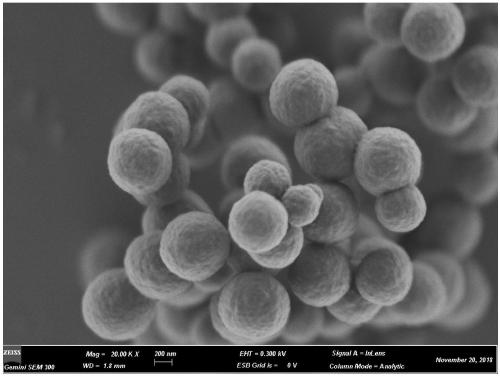

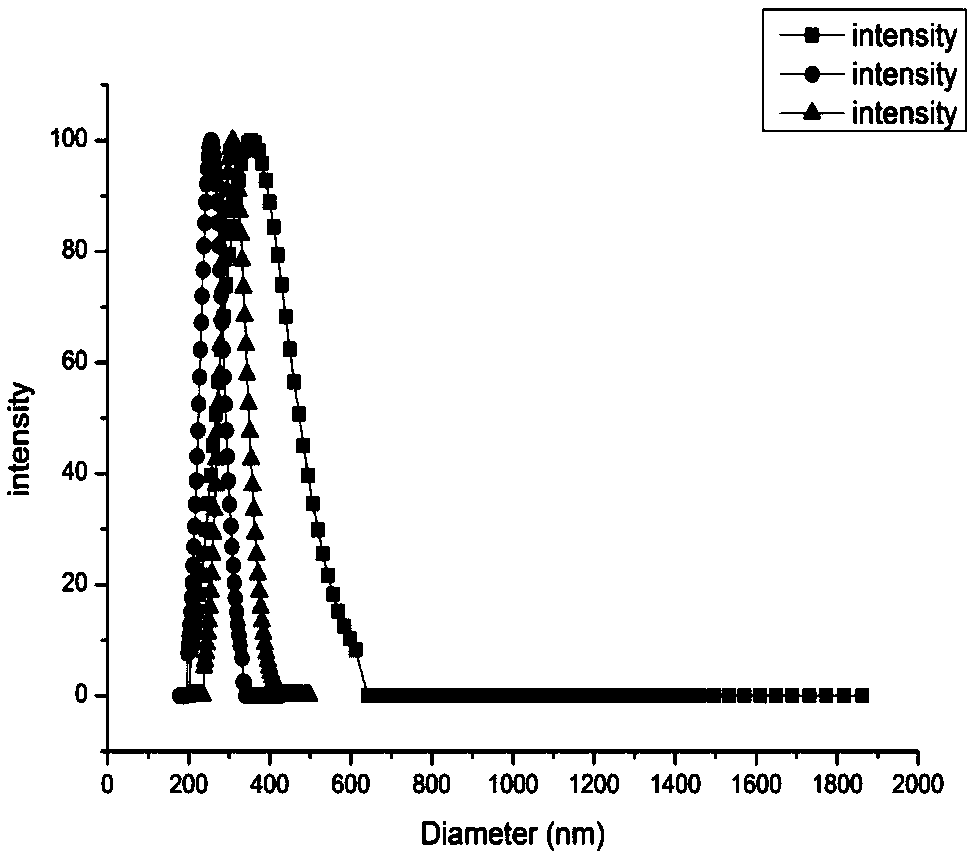

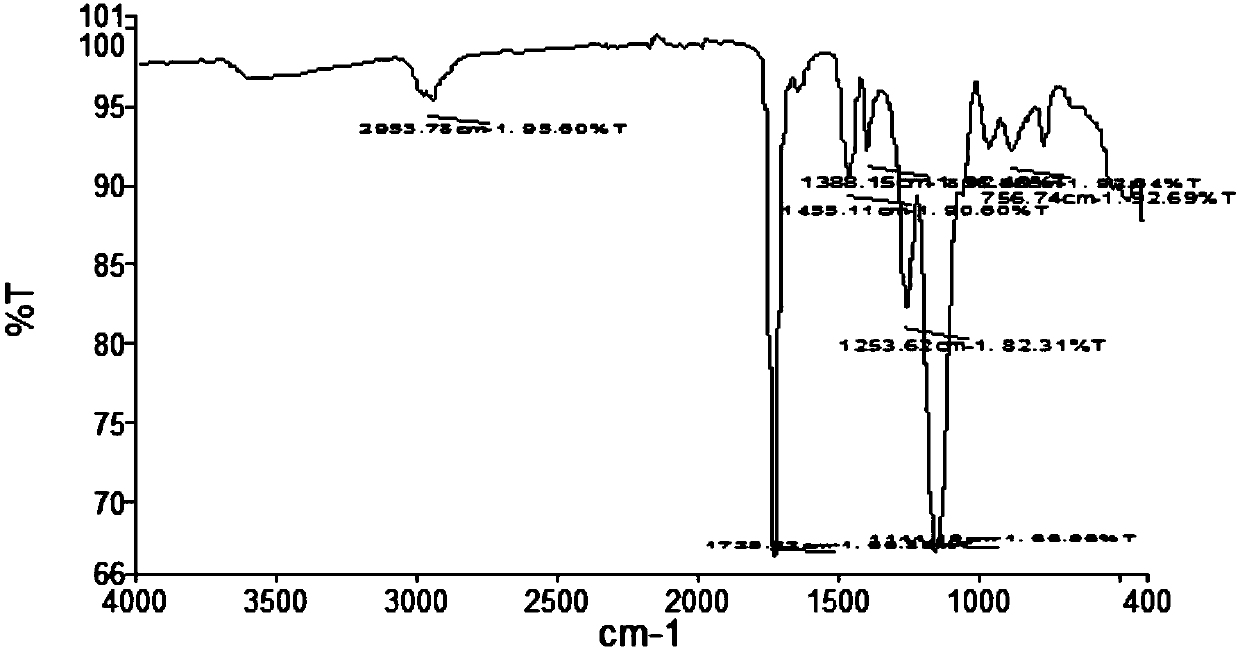

[0023] The preparation method of diisononyl phthalate molecularly imprinted microspheres in this example, the preparation method comprises the following steps:

[0024] Step 1: Add 0.5mmol template molecule diisononyl phthalate and 3mmol functional monomer methacrylic acid in molar ratio to 200mL acetonitrile, and then ultrasonically mix thoroughly to form a mixed solution, which is left to stand at 4°C 12 hours;

[0025] Step 2: Add 10 mmol of ethylene glycol dimethacrylate as a crosslinking agent and 60 mg of azobisisobutyrocyanide as an initiator to the mixture in step 1. After mixing, blow nitrogen gas for 20 minutes to remove oxygen. In a water bath with a heat-collecting magnetic stirrer, stir and react at 65°C for 24 hours;

[0026] Step 3: After the reaction, cool to room temperature, and centrifuge the reaction mixture at a speed of 10,000 rpm for 15 minutes to collect the precipitated polymer; then use a large amount of methanol-acetic acid mixture (v / v=9:1) to repe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com