Nylon crystal reinforced epoxy resin coating and preparation method thereof

A technology of epoxy resin coating and epoxy resin, which is applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., and can solve poor toughness, insufficient transverse performance and interlayer shear strength, and poor impact damage resistance And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The epoxy resin coating without adding nylon crystal reinforced is prepared according to the following proportions (mass percentage):

[0019] Epoxy resin 69.2%;

[0020] Curing agent is 20.7%;

[0021] Nylon-6 0%;

[0022] Hexafluoroisopropanol 10%;

[0023] 1ml each of leveling agent and defoamer;

[0024] Add nylon-6 to the hexafluoroisopropanol solvent, seal and stand for 5 hours to completely dissolve, then place the epoxy resin in an oven, heat it at 60 °C for 15 min, and after the viscosity drops, take an appropriate amount of epoxy resin. The resin was added to the nylon-6 / hexafluoroisopropanol system. The nylon-6 / hexafluoroisopropanol / epoxy resin system was placed on a constant temperature magnetic stirrer, a magnetic stirring bar was added, and it was set to stir at room temperature for 2 h until the system was uniform, colorless and transparent. Add epoxy resin curing agent, 1ml leveling agent and 1ml defoamer into the blend system, stir well with a glas...

Embodiment 2

[0026] The epoxy resin coating reinforced by nylon crystals is prepared according to the following proportions (mass percentage):

[0027] Epoxy resin 67.3%;

[0028] Curing agent is 20.2%;

[0029] Nylon-6 2.5%;

[0030] Hexafluoroisopropanol 10%;

[0031] 0.5ml each of leveling agent and defoamer;

[0032] Add nylon-6 to the hexafluoroisopropanol solvent, seal and stand for 5 hours to completely dissolve, then place the epoxy resin in an oven, heat it at 60 °C for 15 min, and after the viscosity drops, take an appropriate amount of epoxy resin. The resin was added to the nylon-6 / hexafluoroisopropanol system. The nylon-6 / hexafluoroisopropanol / epoxy resin system was placed on a constant temperature magnetic stirrer, a magnetic stirring bar was added, and it was set to stir at room temperature for 2 h until the system was uniform, colorless and transparent. Add epoxy resin curing agent, leveling agent and defoamer into the blend system, stir well with a glass rod, seal and...

Embodiment 3

[0034] The epoxy resin coating reinforced by nylon crystals is prepared according to the following proportions (mass percentage):

[0035] Epoxy resin 65.4%;

[0036] Curing agent is 19.6%;

[0037] Nylon-6 5%;

[0038] Hexafluoroisopropanol 10%;

[0039] 1ml each of leveling agent and defoamer;

[0040] Add nylon-6 to the hexafluoroisopropanol solvent, seal and stand for 5 hours to completely dissolve, then place the epoxy resin in an oven, heat it at 60 °C for 15 min, and after the viscosity drops, take an appropriate amount of epoxy resin. The resin was added to the nylon-6 / hexafluoroisopropanol system. The nylon-6 / hexafluoroisopropanol / epoxy resin system was placed on a constant temperature magnetic stirrer, a magnetic stirring bar was added, and it was set to stir at room temperature for 2 h until the system was uniform, colorless and transparent. Add a curing agent, a drop of leveling agent, and a drop of defoamer to the blend system, which is about 30% of the mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

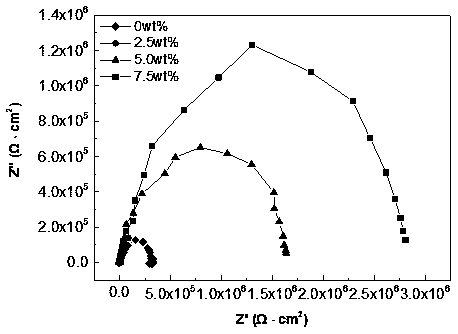

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com