Technology for processing saturated steam on the basis of biomass fuel

A biomass fuel and processing technology, which is applied in sustainable manufacturing/processing, petroleum industry, chemical industry, etc., can solve the problems that liquid cannot be recycled, cannot generate saturated steam, and has poor energy saving and environmental protection effects, so as to save resources. , The effect of low production cost and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

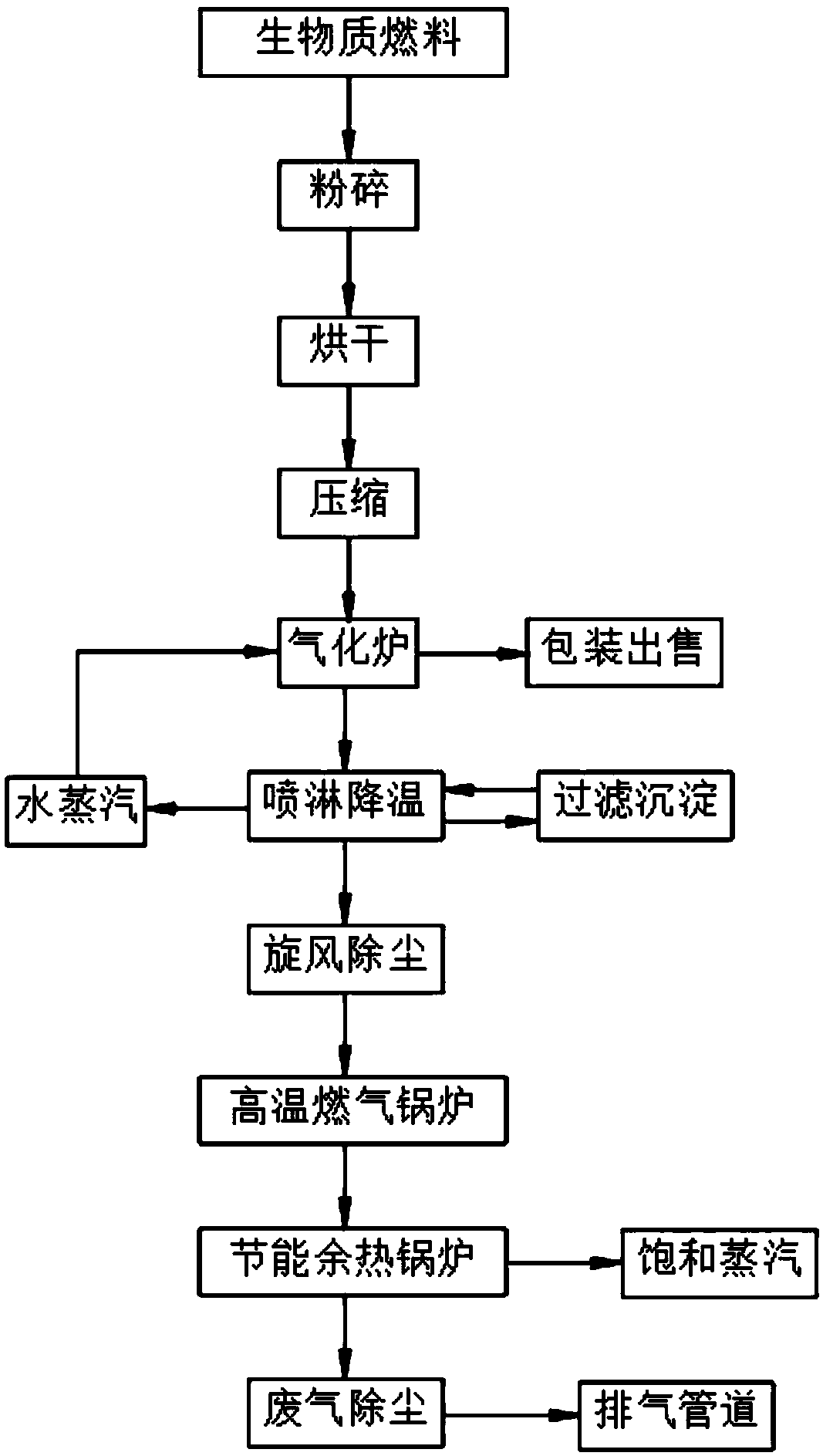

[0025] see figure 1 , in an embodiment of the present invention, a process for processing saturated steam based on biomass fuel, the specific processing process is the following steps:

[0026] 1): Collect biomass raw materials, and carry out crushing treatment to improve the uniformity of biomass fuel combustion;

[0027] 2): Dry the pulverized biomass fuel to ensure its full combustion;

[0028] 3): The dried biomass fuel is compressed by extrusion molding;

[0029] 4): The compressed biomass raw material is transported to the gasifier by means of the conveying device, and the gasification treatment of the biomass fuel is carried out. During the gasification process, a catalyst is added to the inside of the gasifier to accelerate the production of reactants from the biomass fuel and promote Biomass gas formation;

[0030] 5): The biomass gas produced in the gasification process enters the spray device through the pipeline for spraying and cooling treatment. At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com