Portable high-precision drop hammer impact testing machine

A drop hammer impact test, high-precision technology, applied in the direction of strength characteristics, the use of devices for measuring the time required to move a certain distance, force/torque/power measuring instruments, etc., can solve problems such as excessive size, and achieve easy assembly, The effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

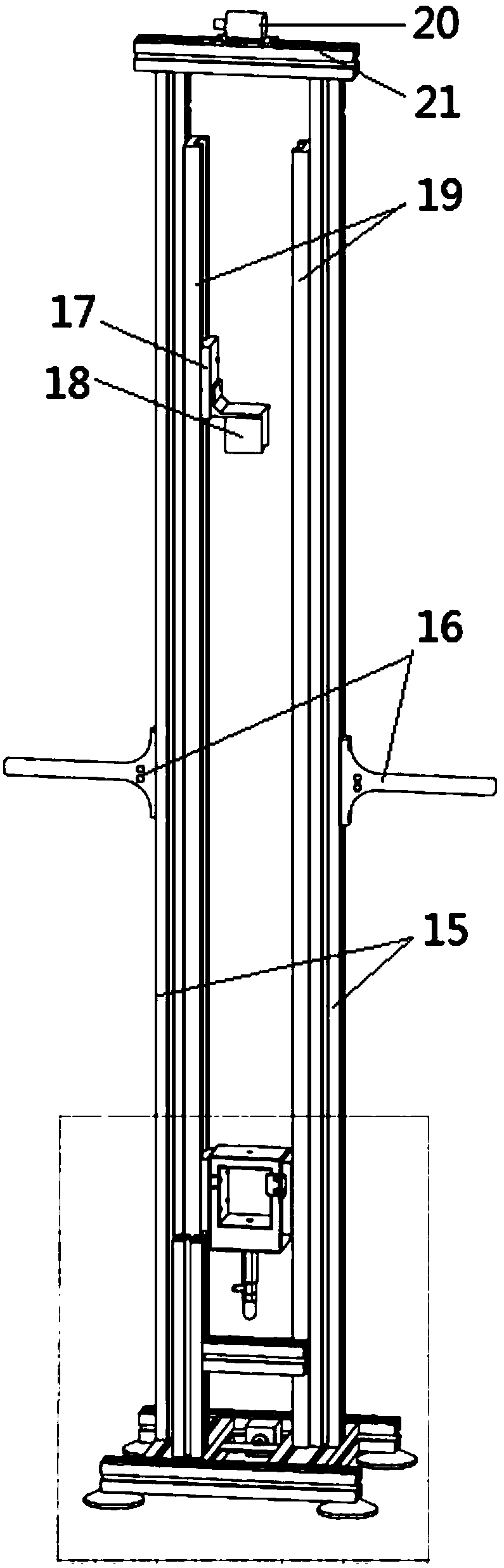

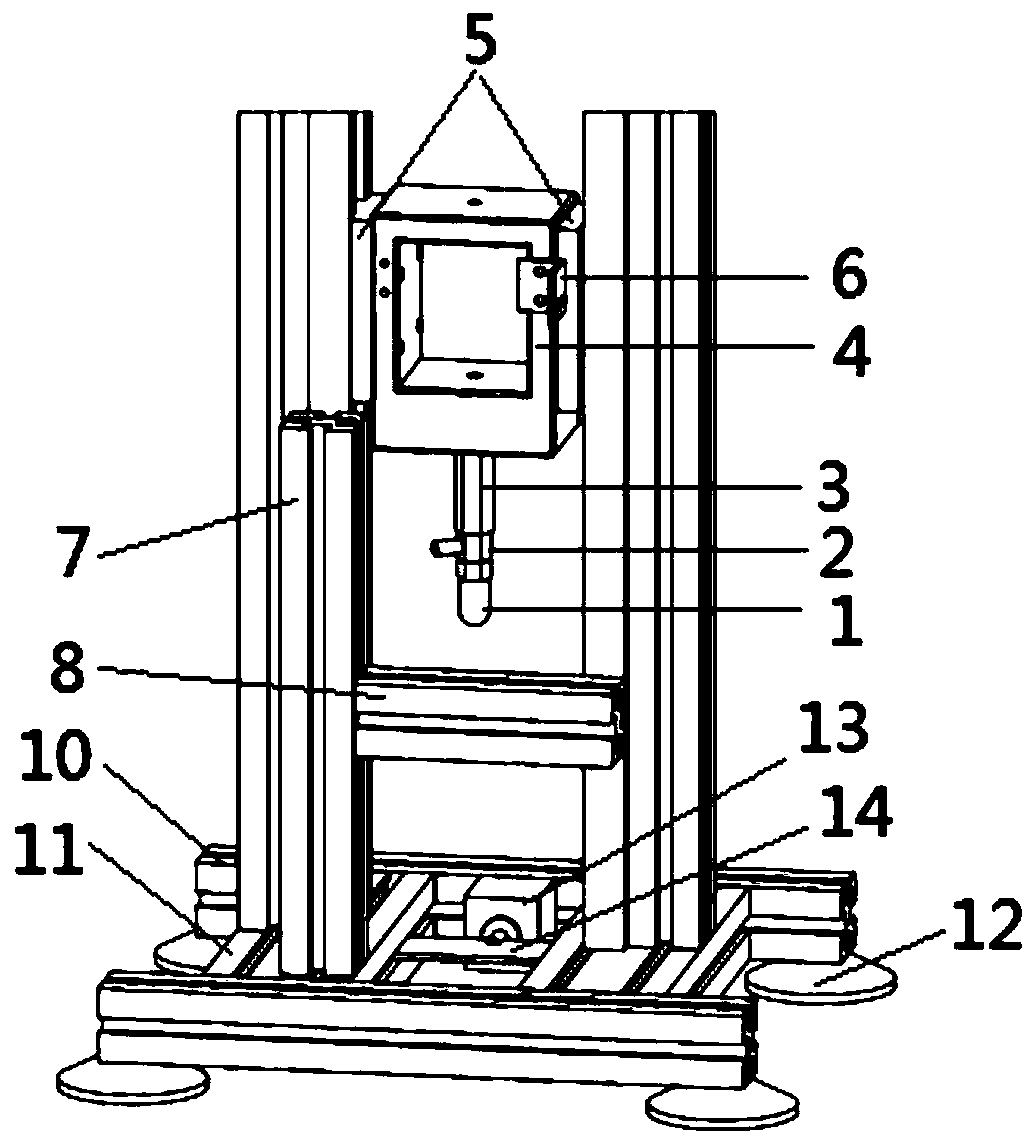

[0040] A portable high-precision drop weight impact testing machine, its structure is as follows: figure 1 As shown, the portable low-speed impact testing machine of this embodiment includes: a falling weight impact assembly, a photoelectric speed measurement system, a guide rail-slider system, a secondary impact prevention device, a lifting release device, and a support frame 15 and other mechanisms. The falling weight impact component is connected to the support frame 15 through the guide rail-slider system, the photoelectric speed measurement system is connected to the falling weight impact component and the support frame, the anti-secondary impact device is fixed at the bottom of the support frame, and the lifting release device is arranged on the support frame.

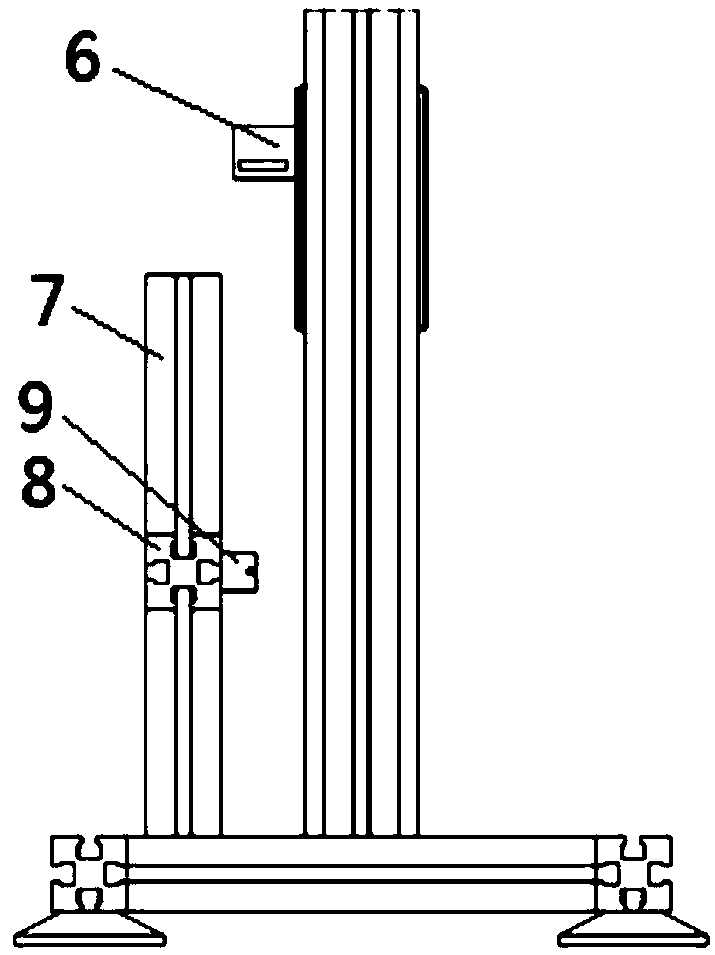

[0041] The following is a further description of the above institutions. The photoelectric speed measurement system is composed of a perforated speed measurement plate 6 arranged on the falling weight impact asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com