An evaluation method of application of a fire coal additive in a power station boiler

A technology for coal-fired additives and power station boilers, applied in data processing applications, instruments, calculations, etc., can solve the problems of neglecting energy saving, environmental protection, long verification period, single and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

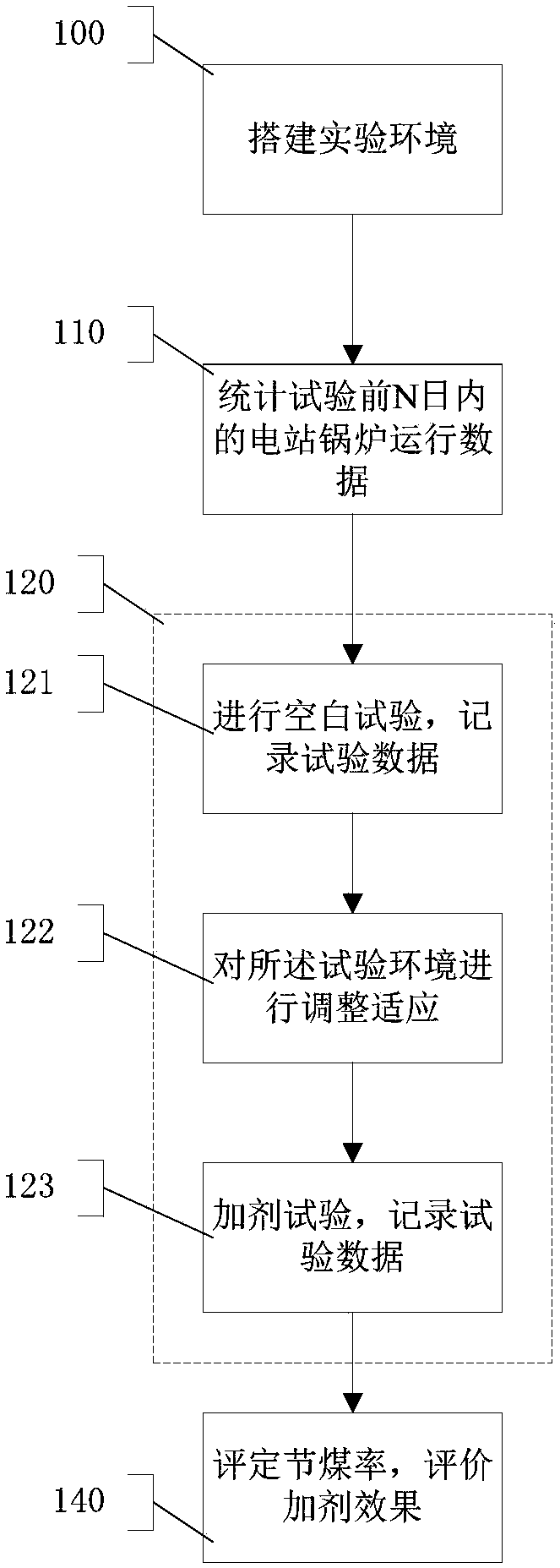

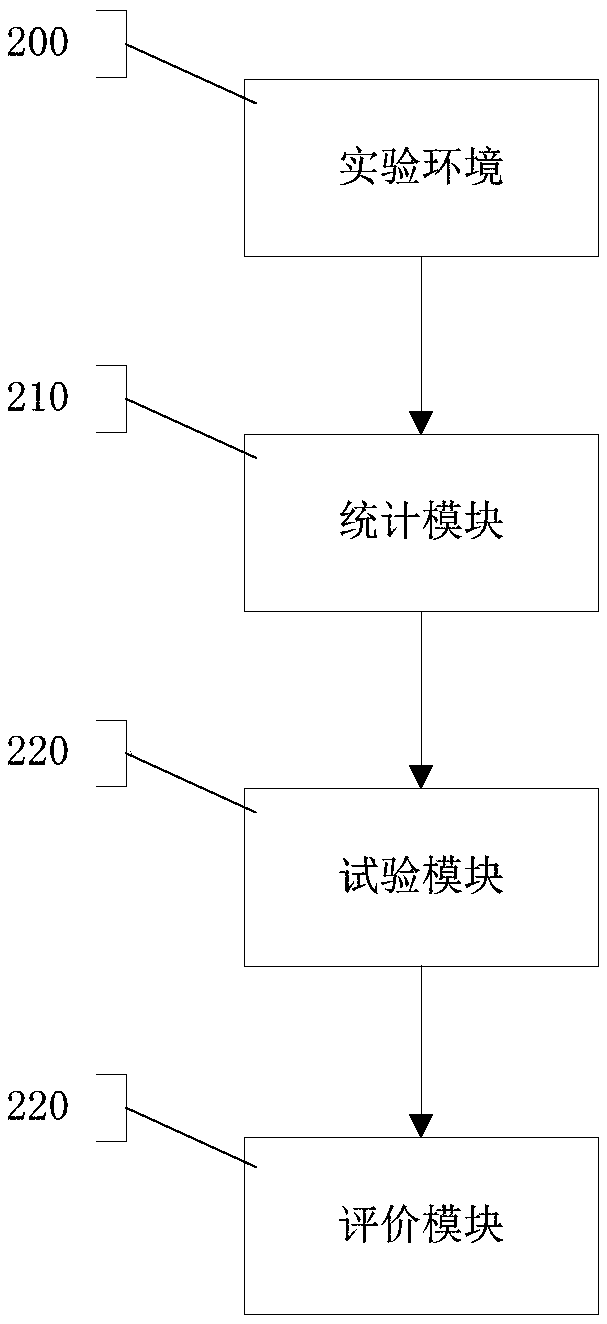

[0085] Such as figure 1 , 2 As shown, step 100 is executed to build the test environment 200, step 110 is executed, and the statistics module 210 counts the operating data of the utility boiler within N days before the test.

[0086] Execute step 120, the test module 220 conducts a test for a period of M days, and records the test collection data in the test. The test collection data includes the calorific value of the coal into the furnace, the amount of coal into the furnace, the power generation, the tail gas parameters, the position of the raw coal bunker, and the amount used for combustion. Oil content, fly ash carbon content, large slag carbon content, SO 2 At least one of emission concentration, NOx emission concentration, boiler exhaust gas temperature and furnace temperature field. . Step 120 includes: a blank stage 121, before the test starts M kDay, according to the test requirements, conduct a blank test and record the test data; adjustment stage 122, M before ...

Embodiment 2

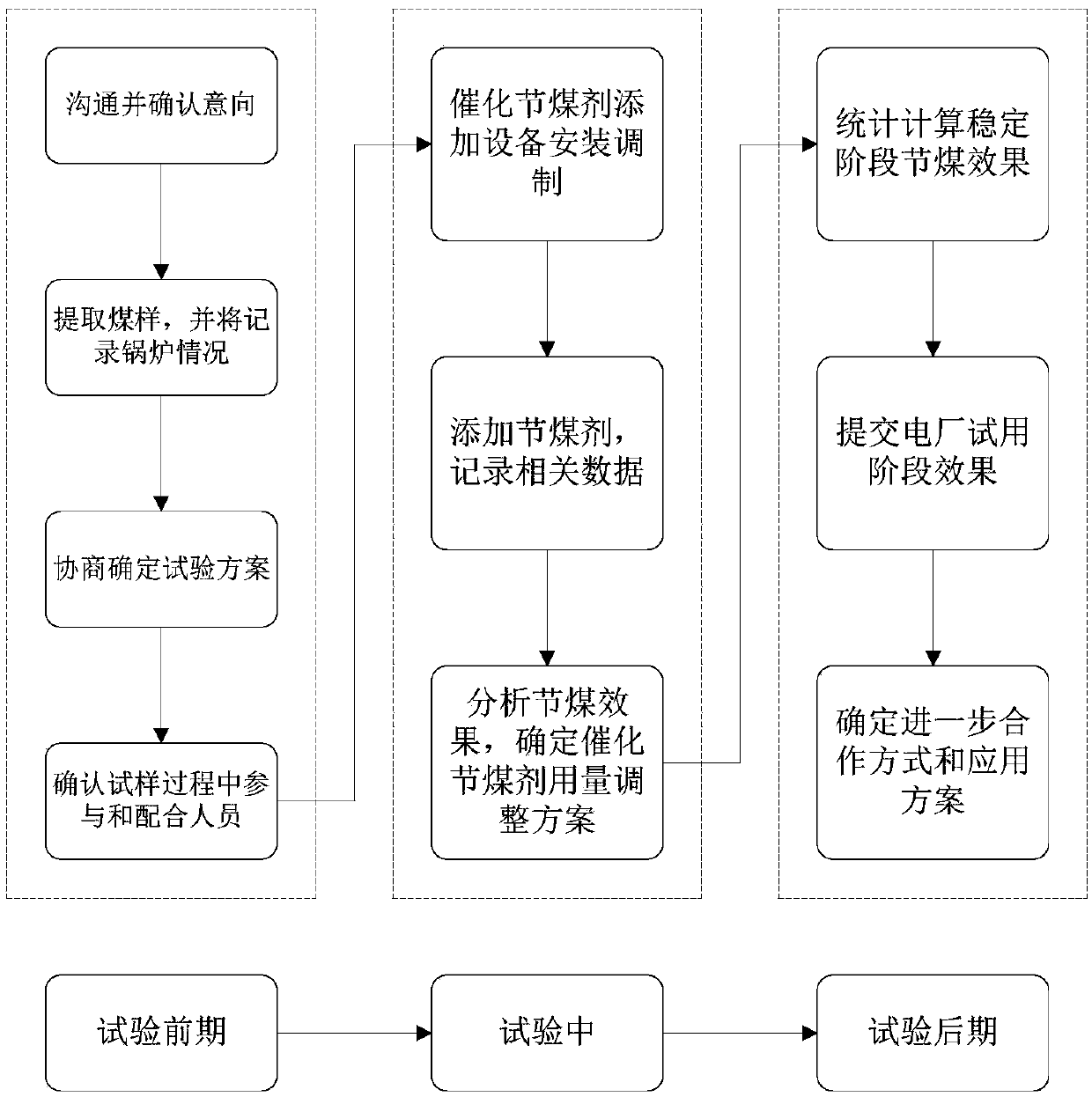

[0103] This embodiment discloses a test flow for the industrial application of coal-fired additives.

[0104] This example takes coal-fired thermal power units as the research object, develops the application of additive energy-saving evaluation methods, conducts coal-fired additive coal-saving system tests for power plant boilers, standardizes the industrial application test process of coal-fired additives, and ensures the authenticity, accuracy and reliability of the test process and results. .

[0105] (1) Test preparation

[0106] (1) Selection of the test boiler. The accuracy of coal-saving effect evaluation will firstly depend on conditions such as boiler load and stable coal quality. A boiler with relatively stable working conditions was selected to carry out a comparative test of the application of coal-fired additives.

[0107] (2) Calibration of measuring instruments. Check and correct the accuracy and stability of measuring instruments such as belt scales and el...

Embodiment 3

[0253] In this embodiment, it is hoped to establish a set of scientific evaluation methods for optimizing energy consumption by adding coal-saving agents to boilers. The pure condensing thermal power unit uses positive balance statistics to calculate the coal consumption of power generation to calculate the coal saving effect, and corrects the unit’s reverse balance index for the evaluation results. The energy-saving effect evaluation and verification method of coal-fired additives for at least one of the speed, power consumption rate of main auxiliary machines, furnace temperature field, and boiler emission indicators, comprehensively evaluate the energy-saving effect of additive combustion optimization; for heating units, use boiler heat production coal consumption, etc. The indicators are used to comprehensively compare and evaluate the energy consumption index levels of thermal power units in the heating period, and use the comprehensive evaluation system of unit energy con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com