Surface defect inspection with large particle monitoring and laser power control

一种表面检验、功率控制的技术,应用在测量装置、半导体/固态器件制造、通过光学手段进行材料分析等方向,能够解决光束功率损失、缺陷检测敏感度、损失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

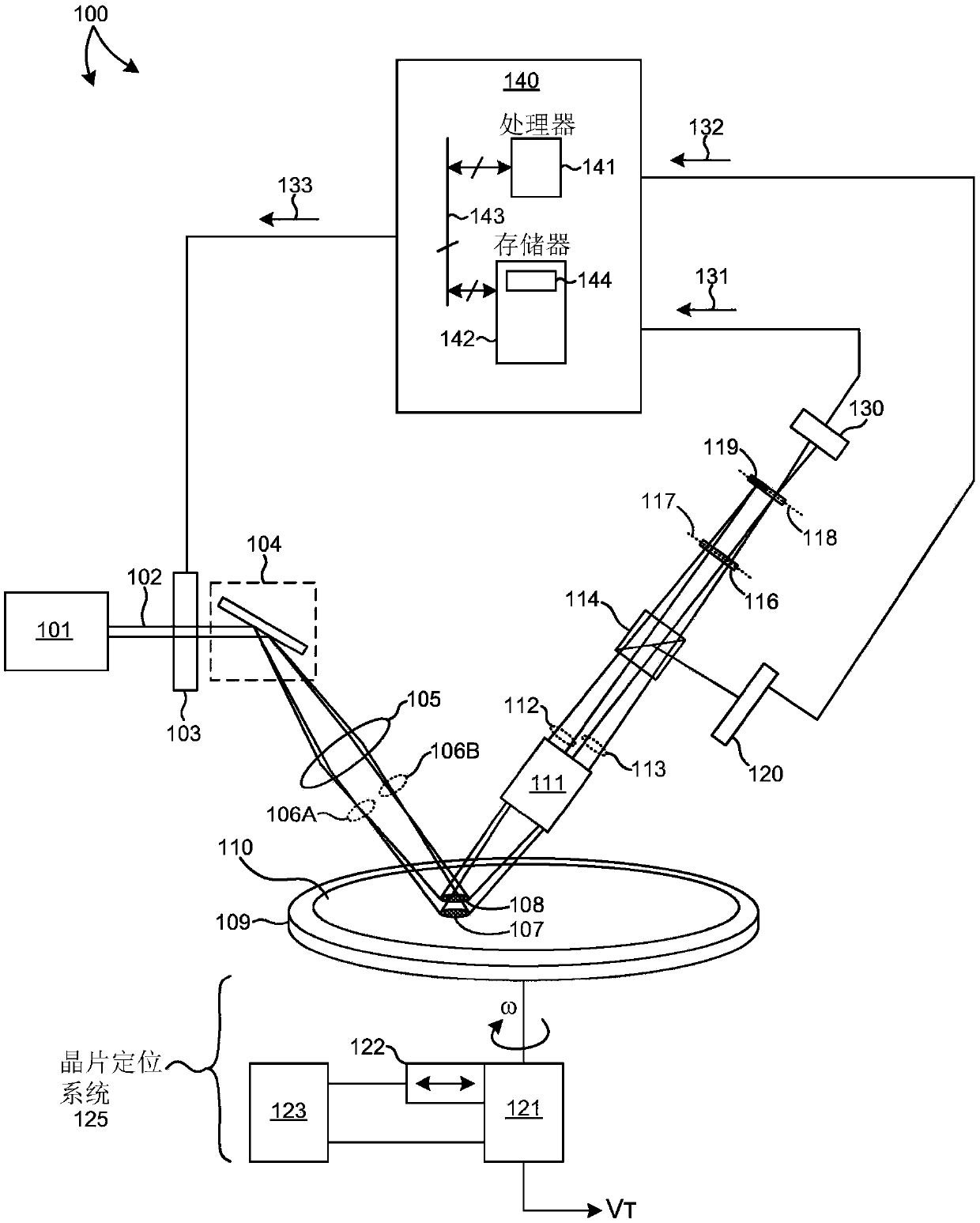

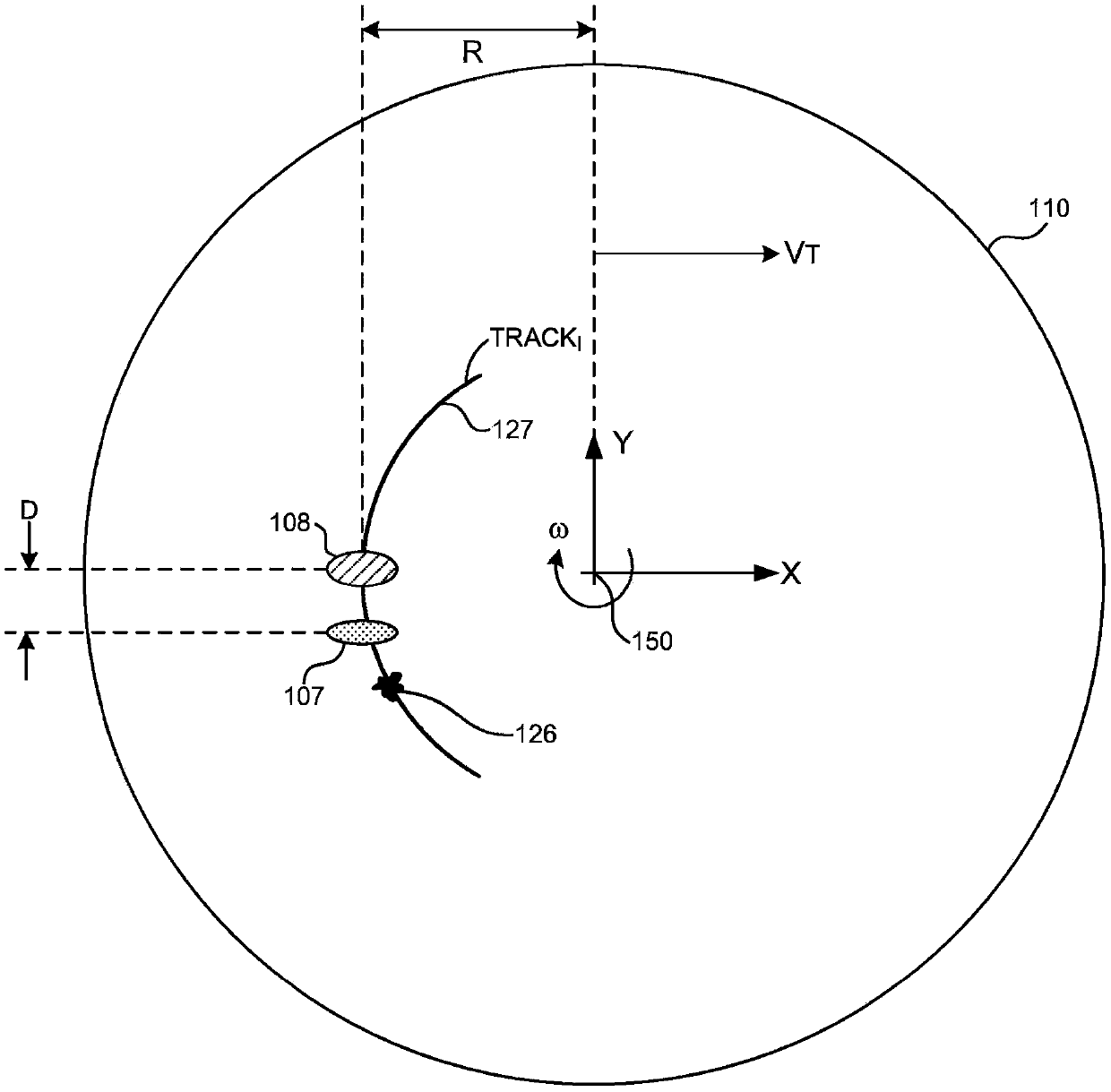

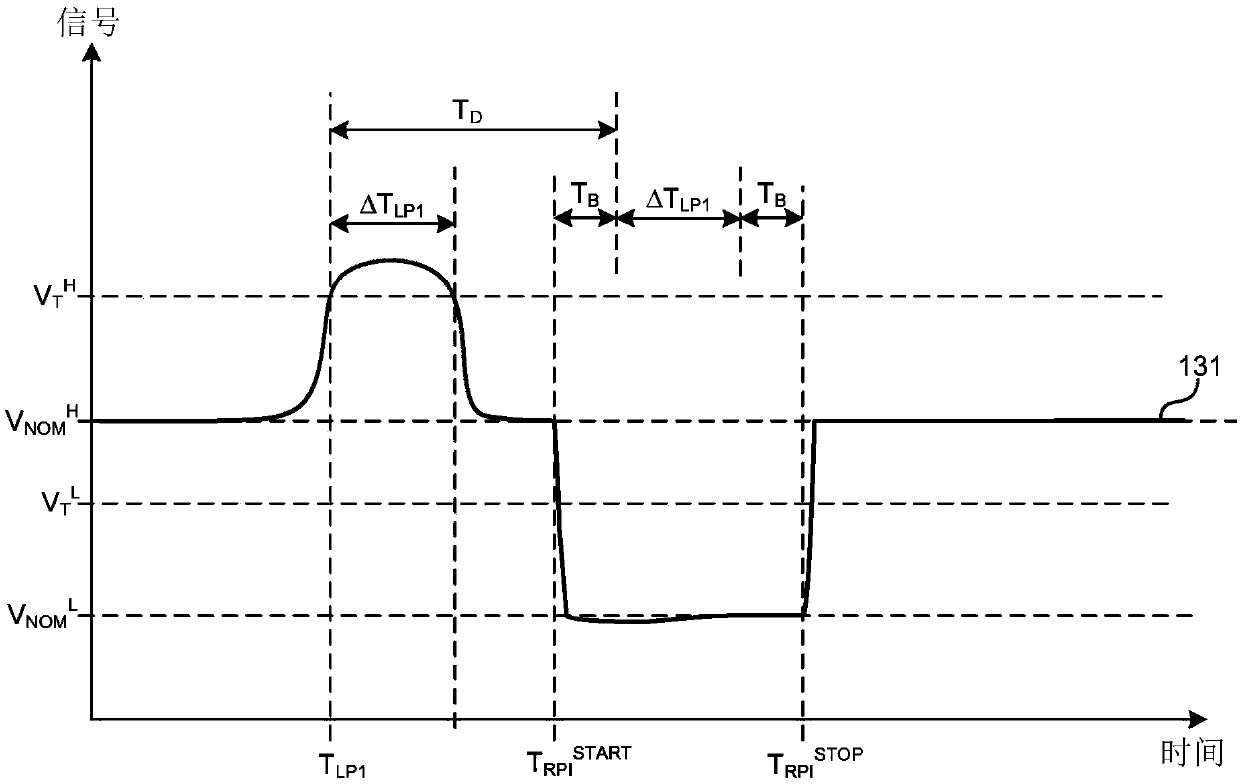

[0029] Reference will now be made in detail to background examples and some embodiments of the invention, examples of which are illustrated in the accompanying drawings.

[0030] The inventive concepts described herein are based on the observation that larger particles (eg, particles larger than microns in diameter) are more likely to be damaged by an incident laser beam than smaller particles. For example, larger particles have a greater surface area and, thus, tend to absorb significantly more power than smaller particles with a smaller surface area. Larger particles also tend to scatter significantly more light than smaller particles due to greater surface area and / or increased surface irregularities. For example, the relative amount of light scattered from a particle of radius R is proportional to the sixth power of the particle's radius. Take advantage of the tendency of large particles to strongly scatter light to reduce thermal damage during surface inspection.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com