Artificial sponge soil, preparation method thereof and application of artificial sponge soil in air layering

A sponge and soil technology, applied in the field of agriculture, can solve the problems of difficult degradation of plastic bags, environmental pollution, cumbersome process, etc., and achieve the effects of preventing the agglomeration of finished products, facilitating plant growth, and enriching mineral nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

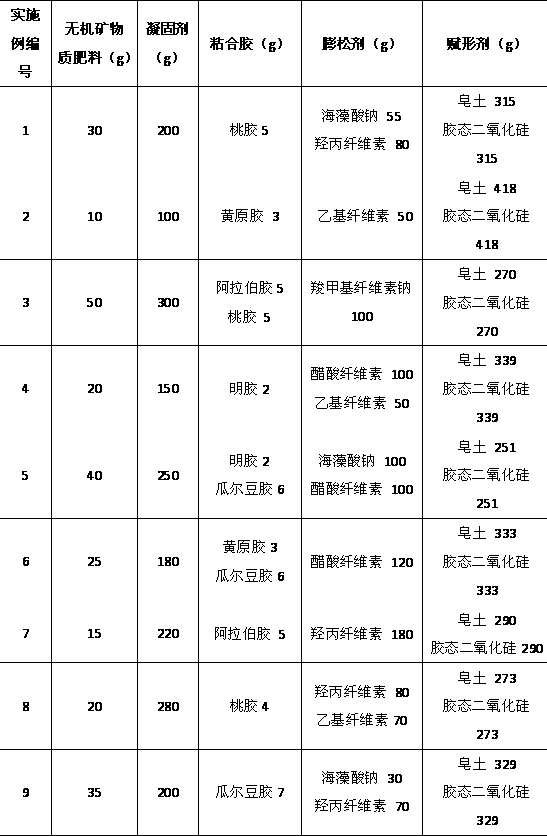

[0037] A kind of artificial sponge soil, in this soil 1000g finished product, inorganic mineral fertilizer 30g, agar 200g, peach gum 5g, sodium alginate 55g, hydroxypropyl cellulose 80g, bentonite 315g, colloidal silicon dioxide 315g.

[0038] Its preparation method is:

[0039] Accurately weigh 30g of inorganic mineral fertilizer, 200g of agar, 5g of peach gum, 55g of sodium alginate, 80g of hydroxypropyl cellulose, 315g of bentonite and 315g of colloidal silicon dioxide, mix them uniformly in a mixer, and pack them.

[0040] The application method in the layering in the air includes the following steps:

[0041] 1) Dilute the finished mixture of the artificial sponge soil with 10-20 times of water and stir evenly.

[0042] 2) Heat step 1 to 90~95°C and maintain the temperature for 20 minutes.

[0043] 3) Place step 2 in a constant temperature bath at 40-50°C to cool and maintain the temperature. At this time, the system is in the form of liquid gel.

[0044] 4) Use a knif...

Embodiment 12

[0047] Product Stability Test

[0048] Take the finished artificial sponge soil samples obtained in Examples 1-10, place them at normal temperature, high temperature and high humidity (constant temperature 40°C, relative humidity 75%), refrigerated at 4°C, and frozen at -20°C. After 0d, 15d, and 30d , 90d and 180d respectively take samples to observe the properties, to see whether there are unstable situations such as discoloration, agglomeration, and deterioration. The results show that the properties basically do not change after 180 days, and have good stability.

Embodiment 13

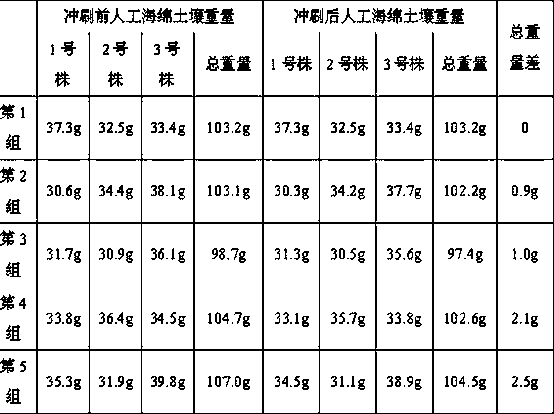

[0050] Rain wash experiment

[0051] Because the artificial sponge soil of the present invention is compared with the real soil used by the traditional layering method, it is completely exposed to the outside air after use without plastic bag protection. If the sponge soil is washed away when it is raining, the economic loss will be very large. Therefore, the investigation of the resistance of the product to the natural environment is of great significance to the promotion of the product, and it is also the quality assurance of the artificial sponge soil.

[0052] Select 15 healthy branches from the same fig tree with little difference in thickness and relative position. Use a scraper to scrape off a circle of bark with a length of about 3cm at the empty fork of each branch to expose the xylem, and then paint all of them with this Invention Example 1 prepares artificial soil, and the weight of the soil that each branch is coated with should be recorded, and 15 branches are ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com