A heat-not-burn cigarette raw material formula design method and its application

A heat-not-burn, design method technology, applied in the field of heat-not-burn cigarettes and heat-not-burn tobacco product leaf group formulations, can solve problems such as lack of thermal analysis data support for tobacco raw materials, and achieve a more scientific and applicable design method. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a method for designing the raw material formula of heat-not-burn cigarettes, which specifically includes the following steps:

[0047] (1) Preliminary selection of tobacco raw materials: according to the inventory of tobacco raw materials, 12 tobacco raw materials of different origins, varieties, grades, parts, shapes and years are selected, shredded, smoked, and then lit. The sensory quality burning and smoking evaluation is carried out under certain conditions, and is carried out according to the "scale value" evaluation method of single-material cigarettes. The specific evaluation indicators are three items: smoke concentration, strength and aroma. There are three grades of high, medium and low. Among them, the high-grade is the one with very strong concentration, great energy and sufficient aroma; the middle-grade is the one with medium concentration, medium energy and medium aroma; Bland is low-grade. Select raw materials with higher smoke...

Embodiment 2

[0063] This embodiment provides a method for designing heat-not-burn cigarette raw material formulations, including the following steps:

[0064] (1) Primary selection of tobacco raw materials under burning and smoking conditions;

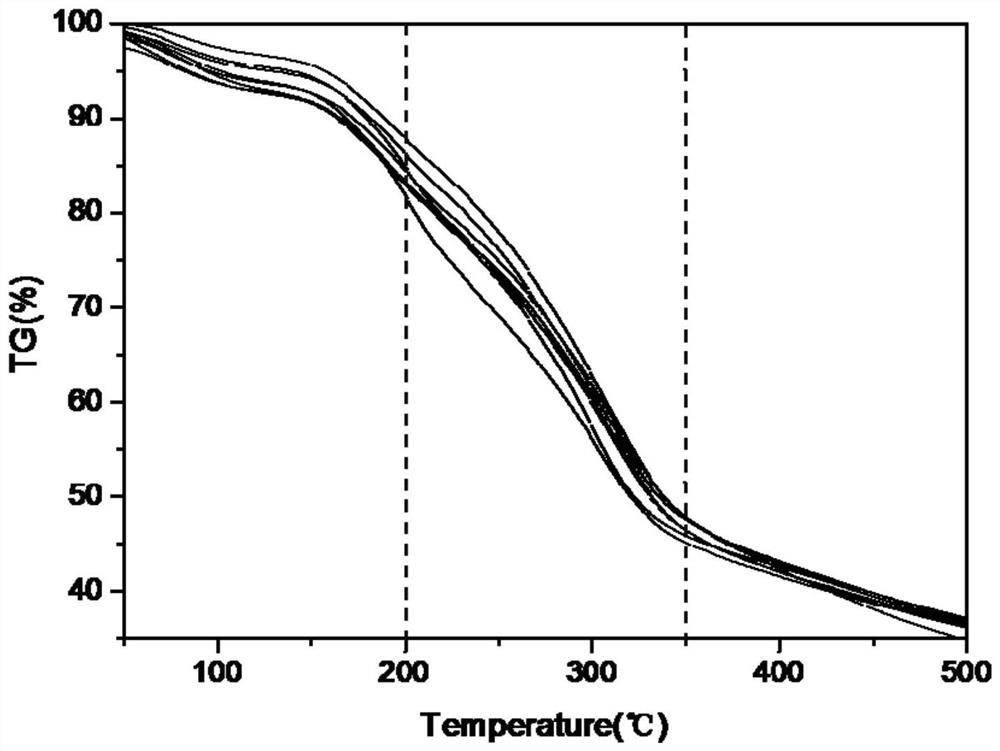

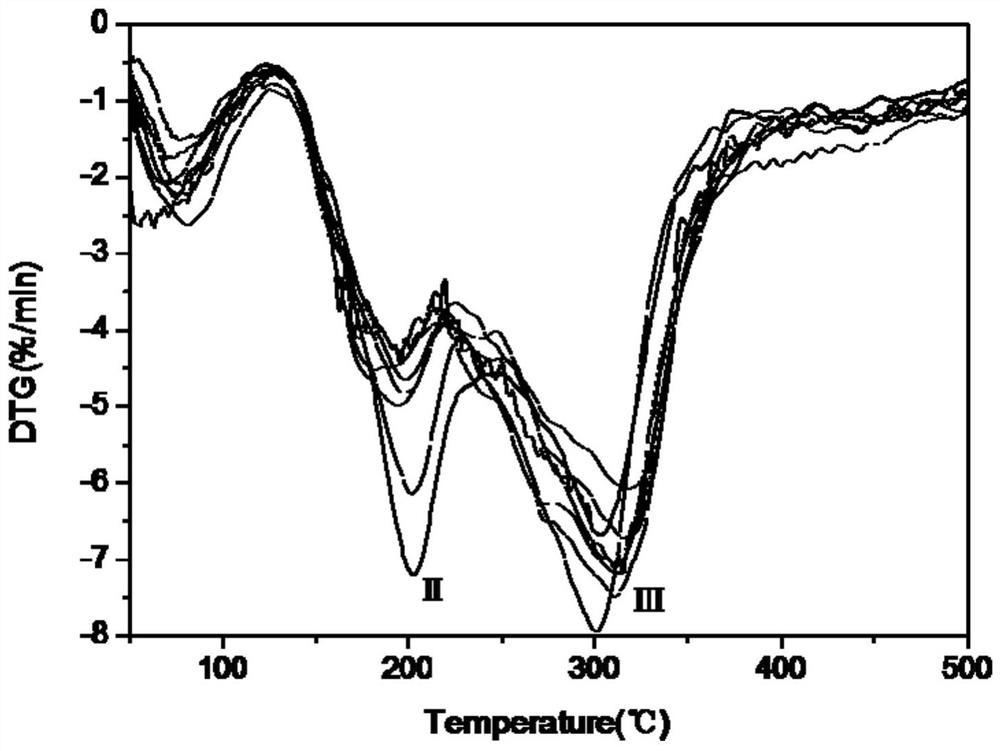

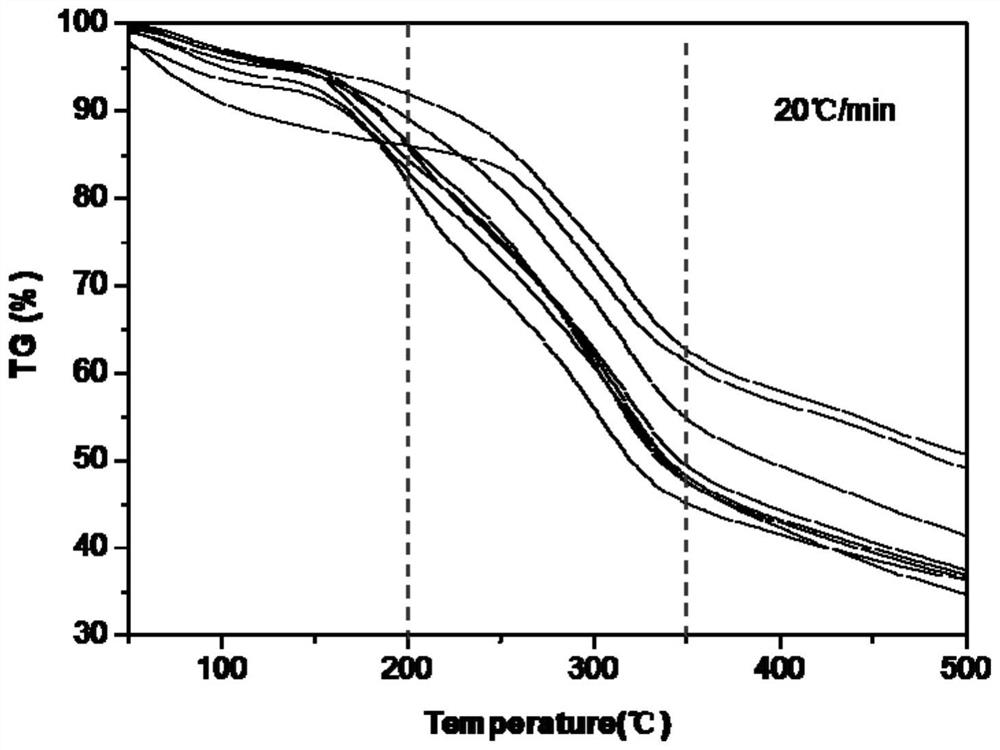

[0065](2) Use thermal analysis-gas chromatography-mass spectrometry (STA-GC / MS) to conduct thermal analysis on the primary selected tobacco raw materials, and obtain the thermogravimetric curve (TG), differential thermogravimetric curve (DTG) and the corresponding temperature at a specific temperature. Pyrolysis product gas chromatography total ion current chromatogram (TIC), according to the thermogravimetric curve, the tobacco raw material with a higher difference in the corresponding residue rate in the specific heating temperature range is preferred, and according to the differential thermogravimetric curve, the corresponding to the maximum weight loss rate is preferred. Tobacco raw materials with higher weight loss rate value, according to TIC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com