A kind of tobacco thin sheet and its preparation method and its substrate, the preparation method of coating liquid

A tobacco sheet and coating liquid technology, applied in the preparation of tobacco sheet, the field of tobacco sheet preparation, can solve the problem of consuming large wood resources, achieve the effect of improving sensory quality, increasing medicinal value, and enhancing internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

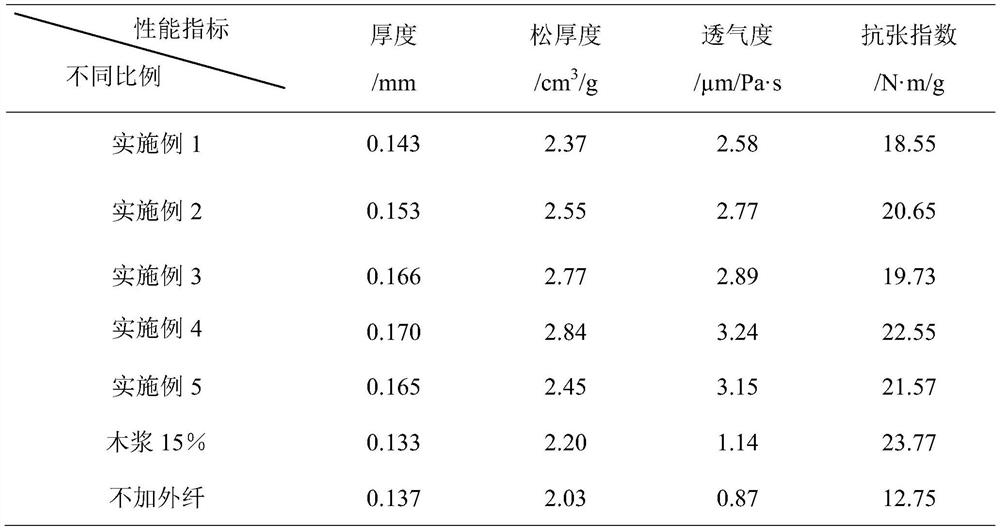

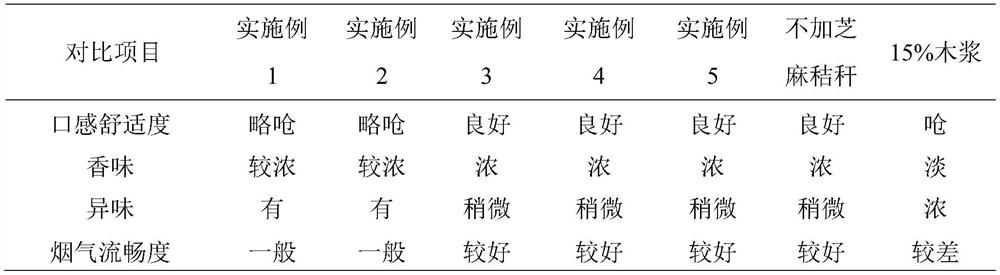

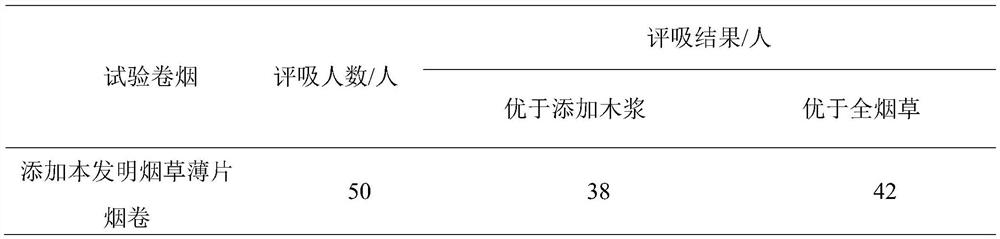

Examples

preparation example Construction

[0036] A method for preparing a base sheet of a tobacco sheet, specifically carried out according to the following steps:

[0037] Step 1: Take sesame stalks with a length of 3 cm to 5 cm including sesame stalks and sesame husks, add ethanol with a mass concentration of 95% to the sesame stalks, and extract at a temperature of 60°C to 80°C for 1h to 3h, wherein the sesame stalks The mass ratio to ethanol is 1:6-9, and the residue after extraction is defibrated using a grinding and splitting machine. The mass concentration of sesame straw during the defibrating treatment is 30% to 45%. The rotating speed is 2800r / min~3000r / min, the grinding distance is 0.85mm, and the beating degree is 15°SR~30°SR sesame straw slurry;

[0038] Step 2, adding hot water at 40°C to 60°C to the waste tobacco leaves to extract for 20min to 40min, wherein the mass ratio of waste tobacco leaves to hot water is 1:4 to 8, and the residue after extraction and the sesame straw slurry are mixed according t...

Embodiment 1

[0061] A kind of preparation method of tobacco sheet, specifically carries out according to the following steps:

[0062] In step a, take sesame stalks with a length of 3 cm including sesame stalks and sesame husks, add ethanol with a mass concentration of 95% to the sesame stalks, and extract at a temperature of 60° C. for 1 hour, wherein the mass ratio of sesame stalks to ethanol is 1 : 6, after carrying out impurity-removing and concentrating the extract, obtaining a mass concentration of 25% sesame stalk concentrate;

[0063] The residue after extraction is defibrillated using a grinding and splitting machine. The mass concentration of sesame stalks during the defibrating treatment is 30%, the rotating speed of the grinding and splitting machine is 2800r / min, and the grinding distance is 0.85mm to obtain beating 15°SR sesame straw slurry;

[0064] Step b, adding 40°C hot water to the waste tobacco leaves to extract for 20 minutes, wherein the mass ratio of the waste tobac...

Embodiment 2

[0070] A kind of preparation method of tobacco sheet, specifically carries out according to the following steps:

[0071] In step a, take sesame stalks with a length of 5 cm including sesame stalks and sesame husks, add ethanol with a mass concentration of 95% to the sesame stalks, and extract at a temperature of 80° C. for 3 hours, wherein the mass ratio of sesame stalks to ethanol is 1 : 9, it is 45% sesame stalk concentrated solution that the mass concentration is obtained after the extract is carried out to remove impurities and concentrate;

[0072] The residue after extraction is defibrillated using a grinding and splitting machine. The mass concentration of sesame stalks during the defibrating treatment is 5%. The degree is 30°SR sesame straw slurry;

[0073] Step b, adding 60°C hot water to the waste tobacco leaves for extraction for 40 minutes, wherein the mass ratio of the waste tobacco leaves to hot water is 1:8, removing impurities from the extract and then concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com