Iron removing, impurity removing and purifying process and system of potash feldspar ore and sodium feldspar by using dry method

A technology of feldspar ore and albite, applied in the field of potassium feldspar, albite dry iron and impurity removal purification process and system, can solve the problems of water pollution, waste of water resources, waste of resources, etc. Good effect, saving water resources, avoiding the effect of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

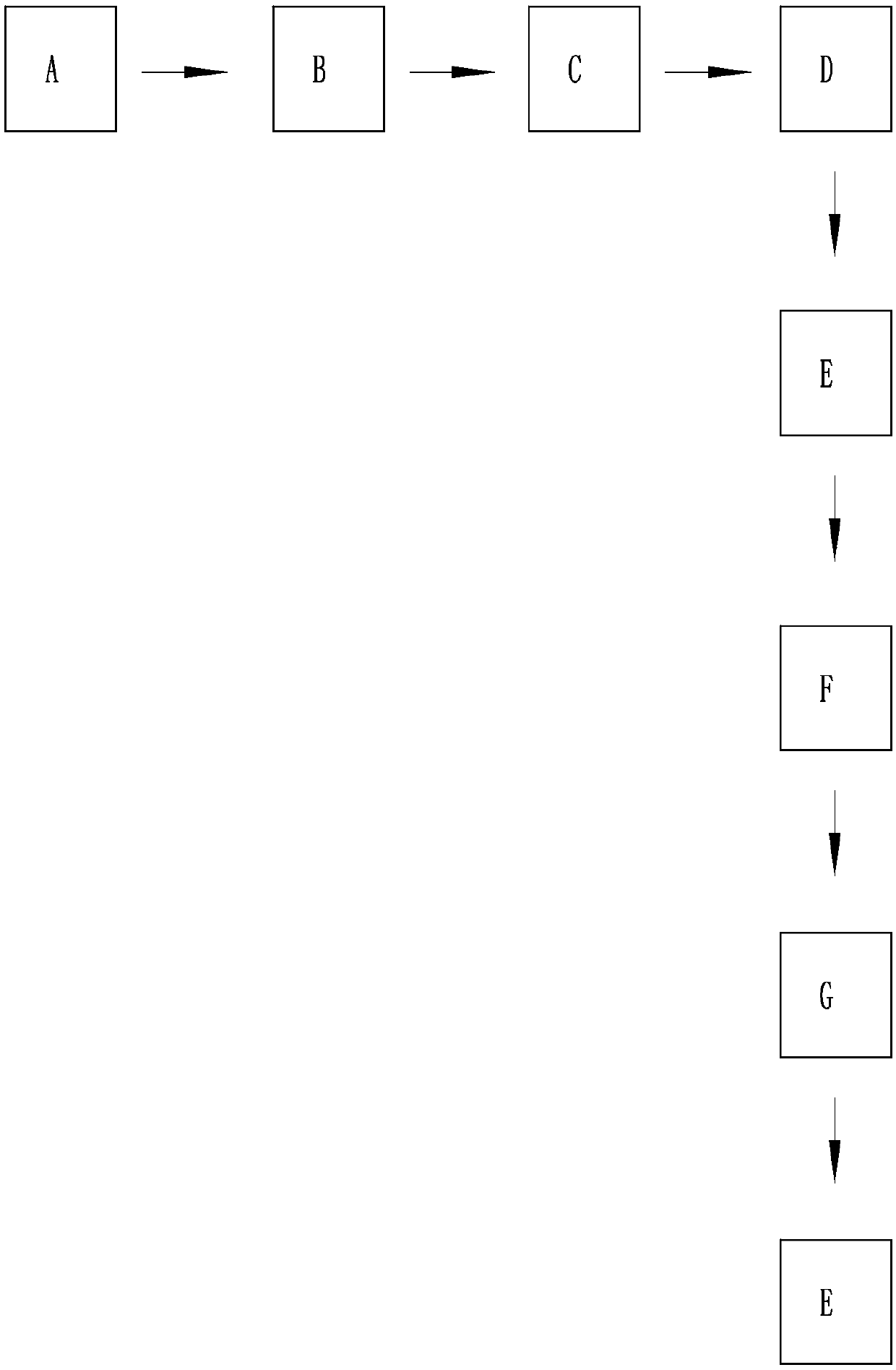

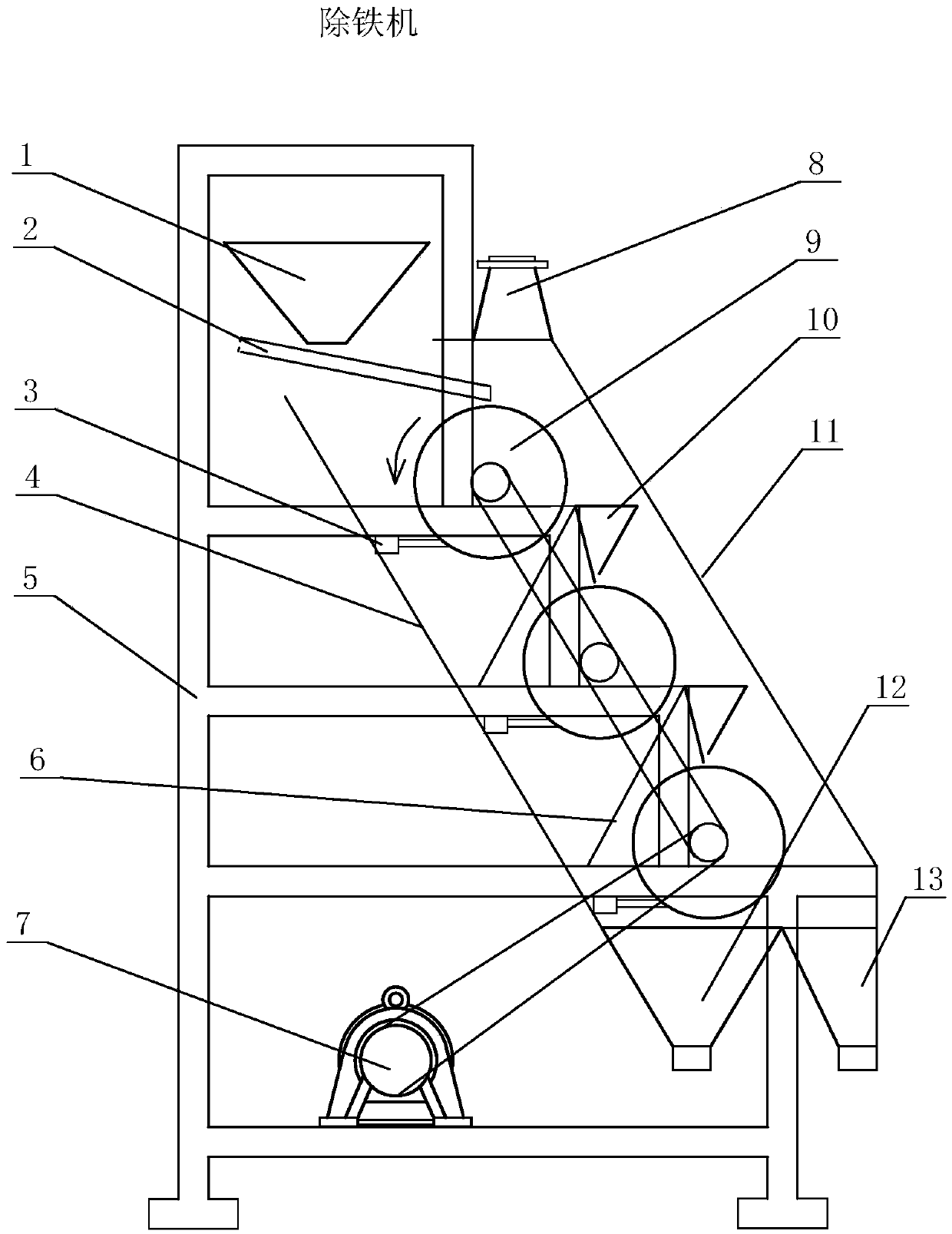

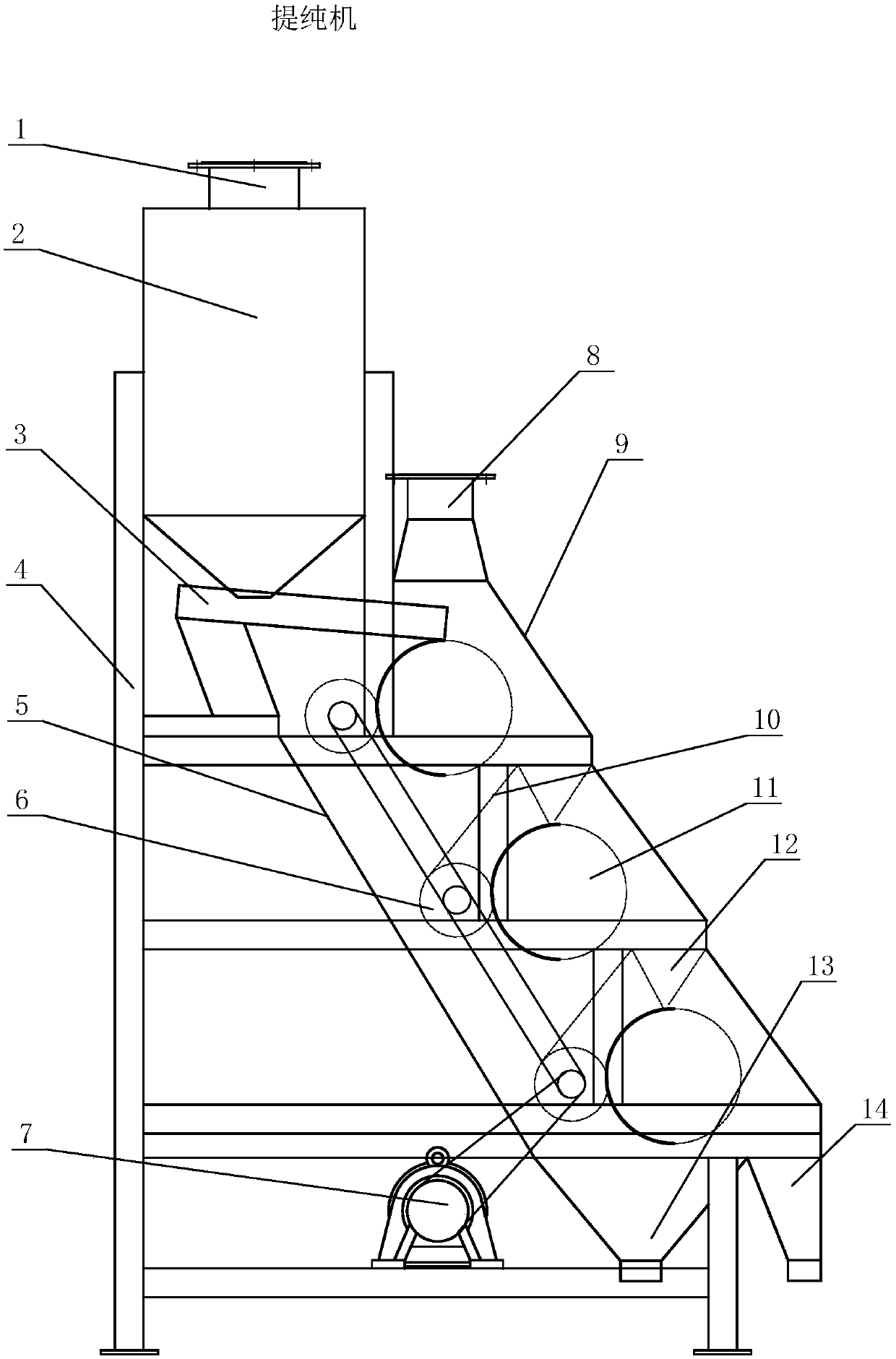

[0055] Such as figure 1 As shown, the potassium feldspar ore and albite dry-process iron and impurity removal purification process and system described in the present invention include a jaw crusher A, a fine crusher B, a powder separator C, and a rare earth supermagnetic iron remover D , Ultramagnetic Purifier E, High Gradient Granular Separator F, Ball Mill G;

[0056] The large feldspar raw ore is crushed to about 35mm by jaw crusher A, and impurities such as fine sand and soil below 2mm are separated by rotary sieve, and the primary removal of impurities is completed;

[0057] After primary impurity removal, the ore enters the fine crusher B to be crushed until the dissociated particle size of the impurity basic monomer is below;

[0058] The fine powder with a particle size less than 0.15mm produced during the crushing process is separated through screeni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com