Aircraft wing compositely driven by shape memory alloy and motor

A memory alloy and wing technology, applied in the field of aircraft wings, can solve problems such as unpublished documents, and achieve the effects of light weight, weight reduction and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

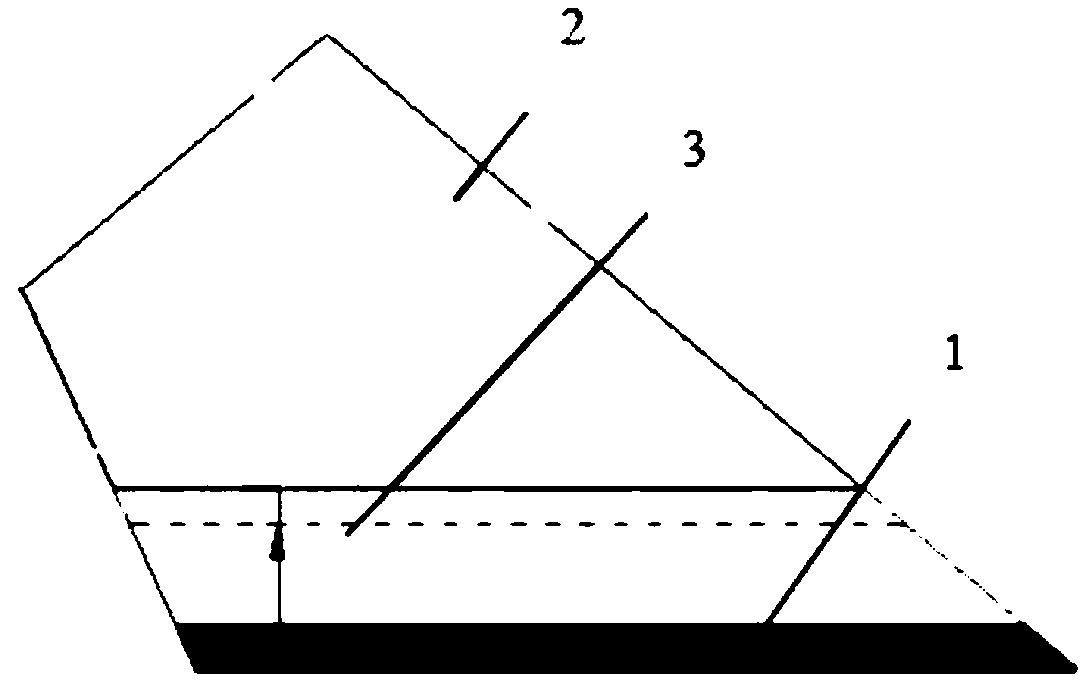

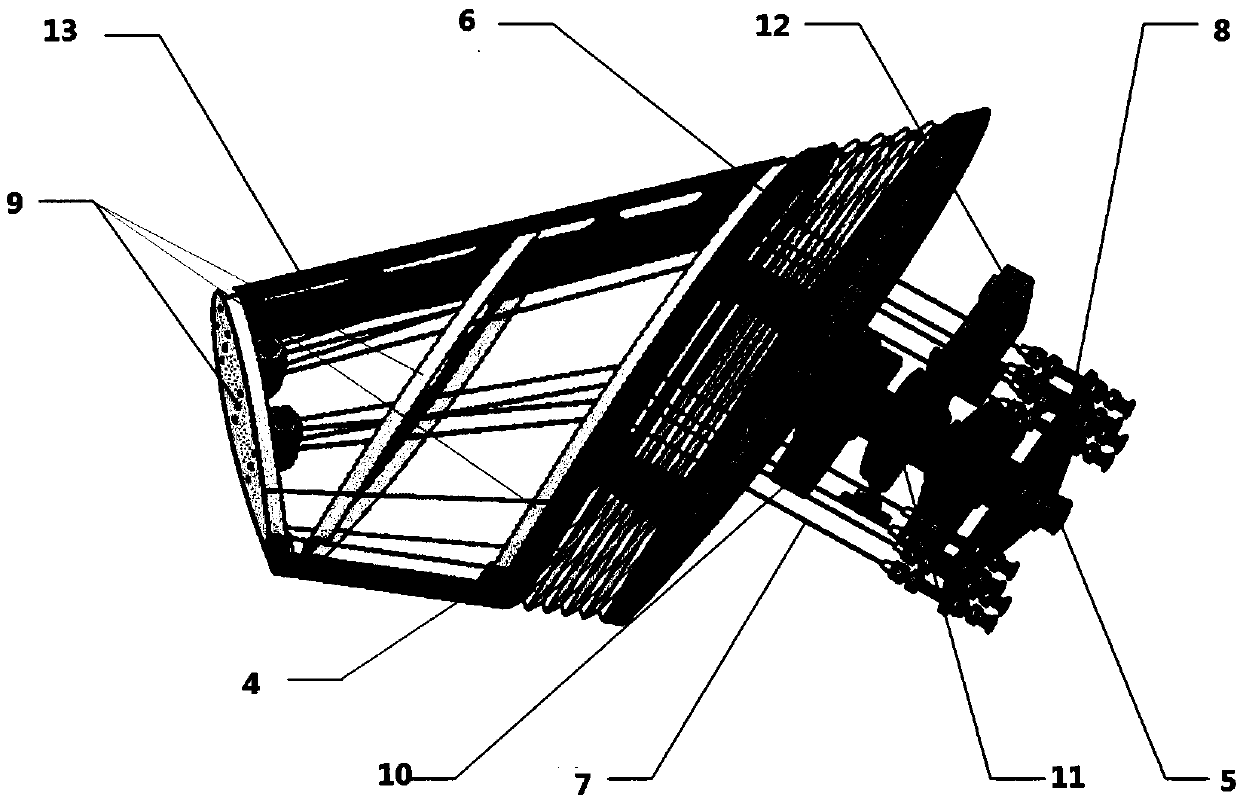

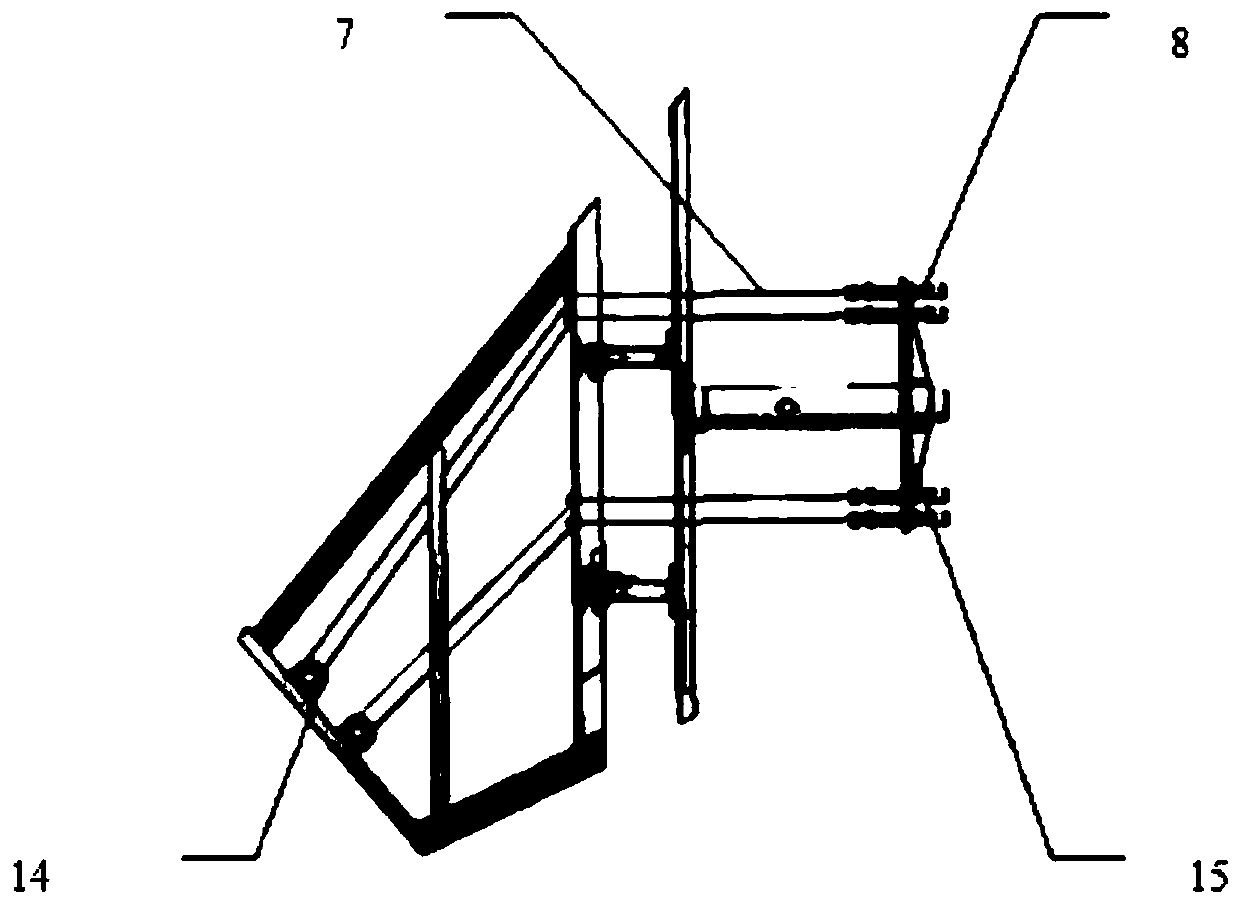

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] Such as Figure 1 to Figure 4 As shown, the present invention includes a fixed wing section 1, a deflecting wing section 2, a deflecting shaft axis 3, a rotary joint 4, a wing pitch axis 5, a corrugated skin 6, an SMA wire 7, a connecting terminal 8, a wing rib 9, and a bearing seat 10. Worm gear 11, stepper motor 12, common skin 13, pulley component 14, wiring board 15, worm 16, bushing 17 and coupling 18, wherein, the fixed wing section 1 is fixed on the wing pitch axis 5 by bolts Above, the deflecting wing segment 2 is connected to the fixed wing segment 1 through two rotating joints 4, the two rotating joints 4 are respectively located on both sides of the wing pitch axis 5, and the axes of the two rotating joints 4 are on the same deflection axis axis 3 Above, the deflection shaft axis 3 is parallel to the fuselage axis. The outside of the connection between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com